Extraction process method of animal grease

A technology of animal fat and extraction process, which is applied in the direction of fat oil/fat production, fat oil/fat refining, and fat oil/fatty acid recovery from waste, and can solve problems such as strong odor, unqualified fire protection, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

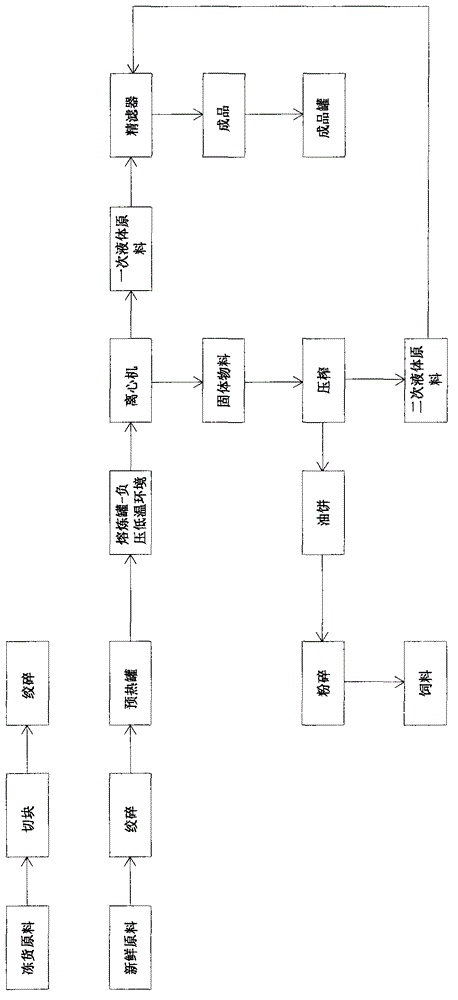

Method used

Image

Examples

Embodiment 1

[0031] Cut the raw materials of frozen goods into 0.8mm particles and enter the preheating tank through Jiaolong. After preheating at 100°C for 30 minutes to precipitate the oil, pump the precipitated oil into the melting tank under a negative pressure of 90Kpa. After heating to 90°C and extracting for 30 minutes, it enters the centrifuge for solid-liquid separation, and the separated primary liquid oil passes through the fine filter and enters the finished product tank for storage. The oil content of the separated solid material is 8% after being squeezed by the press, and the finished oil index is as follows: acid value 2.5mgKOH / g oil, moisture 0.5%, color is 6# color, peroxide value 1.5mmol / kg, and negative pressure and low temperature The gas extracted from the smelting tank under extraction is treated by environmental protection equipment and then discharged into the atmosphere. The air in the smelting workshop is fresh and has no peculiar smell.

Embodiment 2

[0032] Example 2, the fresh raw materials are minced to 0.8mm particles and then passed through Jiaolong into the preheating tank. After preheating at 100°C for 30 minutes, the precipitated oil is pumped into the melting tank and heated to 90Kpa under negative pressure. After extraction at 90°C for 30 minutes, it enters the centrifuge for solid-liquid separation, and the separated primary liquid oil passes through the fine filter and enters the finished product tank for storage. The oil content of the oil residue is 8% after being squeezed by the press. The finished oil index is as follows: acid value 2.6mgKOH / g oil, water content 0.4%, color 6#, peroxide value 1.4mmol / kg. And the gas extracted from the smelting tank under negative pressure and low temperature extraction is discharged into the atmosphere after being treated by the environmental protection agency, and the air in the smelting workshop is fresh and has no peculiar smell.

Embodiment 3

[0033] Example 3: Cut the raw materials of frozen goods into pieces and grind them into 0.5mm particles, and then enter the preheating tank through Jiaolong. After preheating at 90°C for 40 minutes, the precipitated oil is pumped into the melting tank under a negative pressure of 85Kpa , heated to 115°C, extracted for 20 minutes, then enters the centrifuge for solid-liquid separation, and the separated primary liquid oil passes through the fine filter and enters the finished product tank for storage. The oil content of the oil residue is 7% after being squeezed by the press. The finished oil index is as follows: acid value 2.2mgKOH / g oil, water content 0.6%, color 6#, peroxide value 1.5mmol / kg. And the gas extracted from the smelting tank under negative pressure and low temperature extraction is discharged into the atmosphere after being treated by environmental protection equipment, and the air in the smelting workshop is fresh and has no peculiar smell.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pov | aaaaa | aaaaa |

| Pov | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com