Sustained-release raw hide swelling agent as well as preparation method and application

A technology of bulking agent and rawhide, applied in the field of preparation of sustained-release rawhide bulking agent, can solve the problems of difficulty in controlling the degree of separation and loosening of collagen fibers, severe swelling effect, etc. mud effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

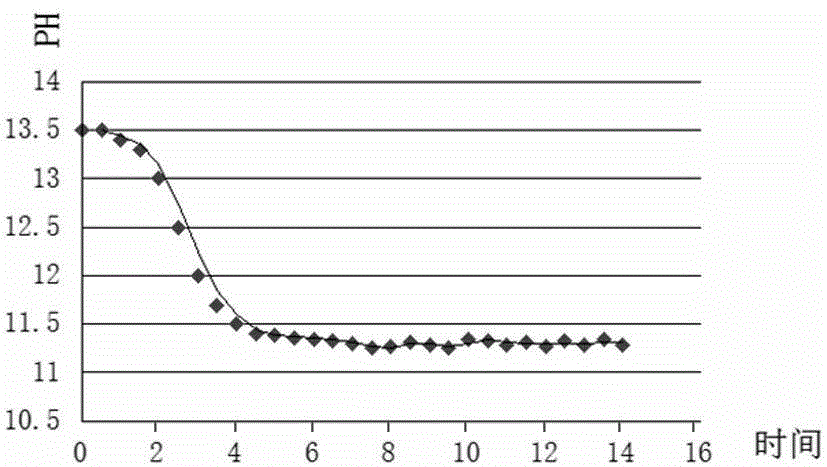

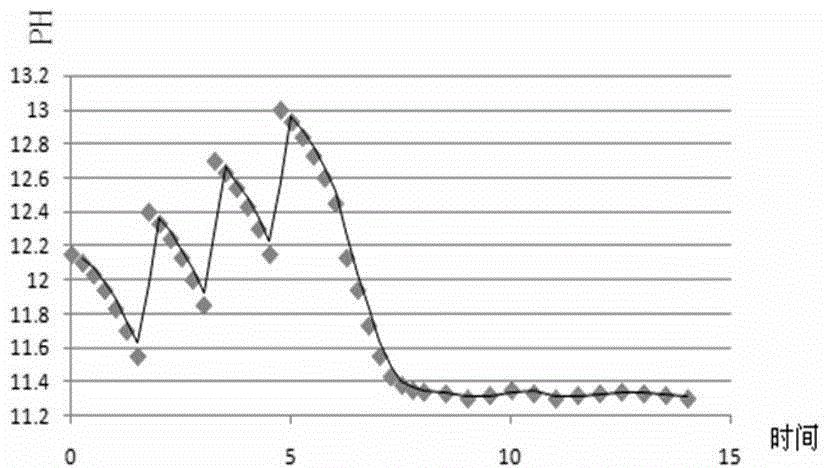

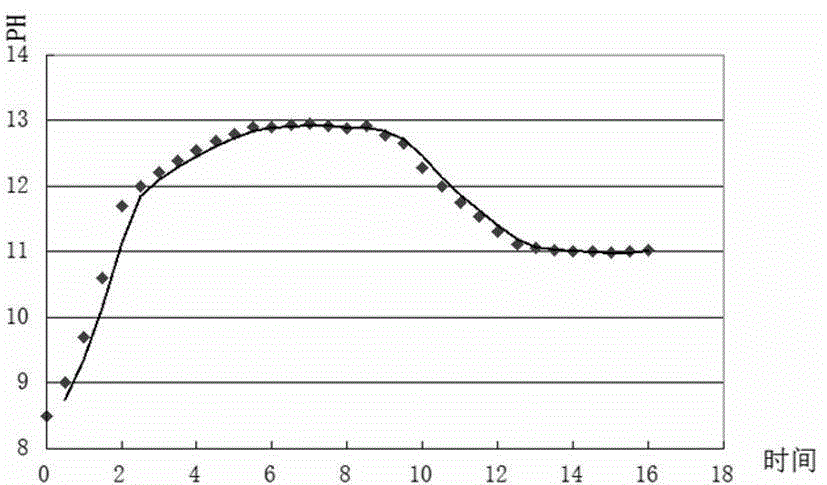

Image

Examples

Embodiment 1

[0044] A slow-release rawhide bulking agent, in the form of granules, has two layers from the inside to the outside, the inner layer is sodium silicate granules, and the sodium silicate granules are covered with polyvinyl alcohol coating.

[0045] The preparation method of this slow-release rawhide bulking agent mainly comprises the following steps:

[0046] (1) Preparation of coating agent

[0047] After dissolving 3 parts by weight of commercially available polyvinyl alcohol PVA-2488 in 50 parts by weight of water at 30 degrees Celsius for 2 hours, add 47 parts by weight of water, stir, heat up to 90 degrees Celsius, stir until the polyvinyl alcohol is fully dissolved, add a small amount of 2 % dilute hydrochloric acid to adjust the pH to 4.0, add 1 part by weight of formaldehyde solution (30%), keep warm at this temperature for 2 hours, adjust the pH of the system to 8.5 with 5% aqueous sodium hydroxide solution, and then cool down for later use;

[0048] (2) Coating agent...

Embodiment 2

[0057] A slow-release rawhide bulking agent, in the form of granules, has two layers from the inside to the outside, the inner layer is sodium silicate granules, and the sodium silicate granules are covered with polycaprolactam coating.

[0058] The preparation method of this slow-release rawhide bulking agent mainly comprises the following steps:

[0059] (1) Preparation of coating agent

[0060] After dissolving 10 parts by weight of commercially available polycaprolactam in 50 parts by weight of water at 30 degrees Celsius for 2 hours, add 40 parts by weight of water, stir, raise the temperature to 90 degrees Celsius, stir until the polycaprolactam is fully dissolved, add a small amount of 5% dilute sulfuric acid to adjust the pH 5.0, add 2 parts by weight of formaldehyde solution (30%), keep warm at this temperature for 2 hours, adjust the pH value of the system to 9.0 with 2% calcium hydroxide aqueous solution, and then cool down for later use.

[0061] (2) Envelope

[...

Embodiment 3

[0070] A slow-release rawhide swelling agent, in the form of granules, with two layers from the inside to the outside, the inner layer is a mixture of sodium silicate and calcium hydroxide particles, and the sodium silicate particles are covered with modified Polyvinyl alcohol coating.

[0071] The preparation method of this slow-release rawhide bulking agent mainly comprises the following steps:

[0072] (1) Preparation of coating agent

[0073] After dissolving 5 parts by weight of commercially available polyvinyl alcohol PVA-1799 in 50 parts by weight of water at 30 degrees Celsius for 2 hours, add 47-40 parts by weight of water, stir, heat up to 90 degrees Celsius, stir until the polyvinyl alcohol is fully dissolved, add A small amount of 3% dilute hydrochloric acid is used to adjust the pH to 4.5, add 1 part by weight of formaldehyde solution (30%), keep warm at this temperature for 2 hours, adjust the pH of the system to 9.0 with aqueous calcium hydroxide solution, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com