Lithium ion secondary battery porous silicon/carbon composite negative electrode material and preparation method thereof

A technology for secondary batteries and negative electrode materials, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as unfavorable industrial production, high elemental cost, high risk, etc., achieve convenient and easy process conditions, and improve the first effect. , the effect of low material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Preparation of silicon aluminum alloy:

[0035] 1) The polyacrylonitrile powder, silicon dioxide powder, and alumina powder with a mass ratio of 10:0.7:1.8 are ball milled and mixed on a planetary ball mill to obtain a primary mixture. The ball milling conditions are: 200 rpm, 5 hours of ball milling, and a ball-to-material ratio of 5:1.

[0036] 2) Put the primary mixture and NaCl with a mass ratio of 1:1 in a boron nitride crucible, N 2 Under air protection, the temperature was raised to 820°C at 5°C / min, and kept for 2 hours. The product was washed with deionized water, filtered with suction, and dried in vacuum to obtain a silicon-aluminum alloy.

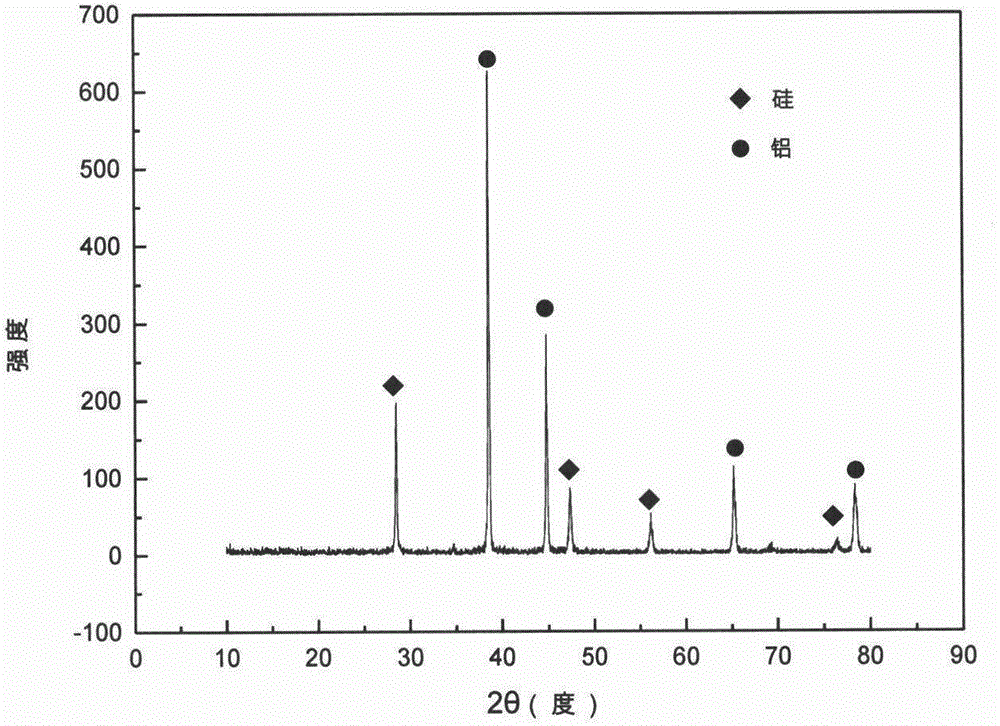

[0037] figure 1 is the X-ray diffraction pattern (XRD) of the silicon-aluminum alloy prepared above. It can be seen from the figure that no other phases are found except the two phases of silicon and aluminum.

[0038] Preparation of porous silicon / carbon composite anode materials:

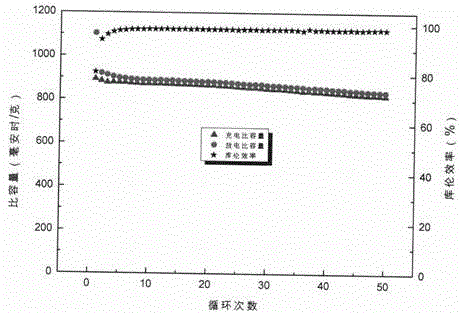

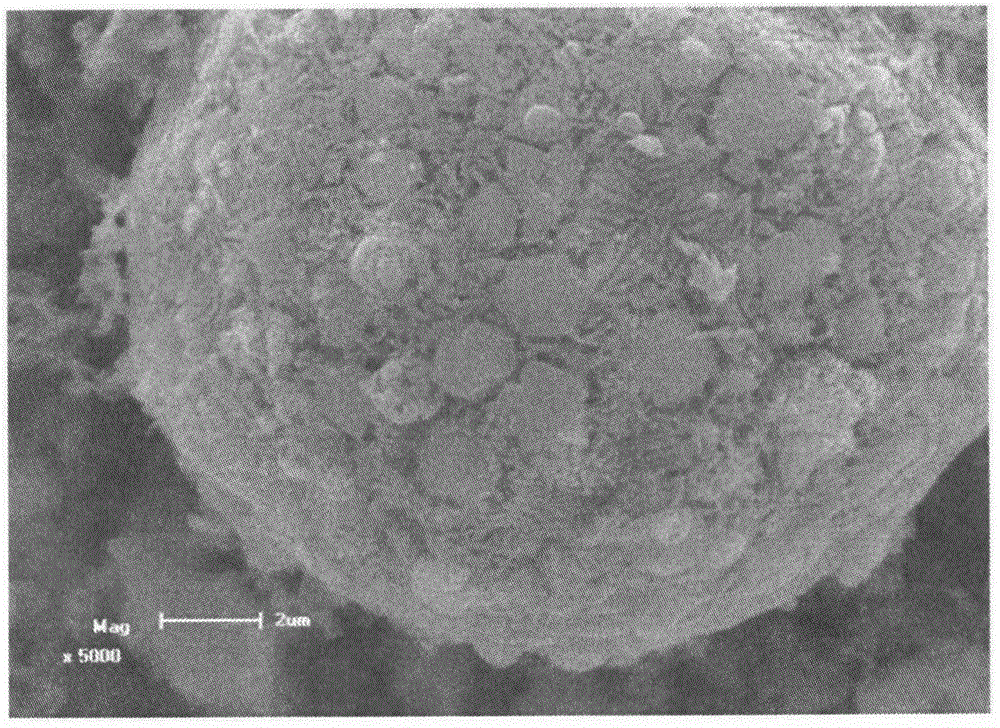

[0039] 1) The above-prepared alumin...

Embodiment 2

[0046] Preparation of silicon aluminum alloy:

[0047] 1) The polyvinyl chloride powder, silicon dioxide powder, and alumina powder with a mass ratio of 10:0.1:2.4 are ball milled and mixed on a planetary ball mill to obtain a primary mixture. The ball milling conditions are: 300 rpm, 20 hours of ball milling, and a ball-to-material ratio of 10:1.

[0048] 2) Mix the primary mixture, KCl, NaCl, CaCl with a mass ratio of 1:4:2:4 2 Place it in a boron nitride crucible, raise the temperature to 760°C at 5°C / min under the protection of Ar gas, and keep it warm for 5h. The product is washed with deionized water, filtered with suction, and dried in vacuum to obtain a silicon-aluminum alloy.

[0049] The X-ray diffraction pattern (XRD) of the silicon-aluminum alloy of above-mentioned preparation and in the embodiment figure 1 similar. It can be seen from the figure that no other phases are found except the two phases of silicon and aluminum.

[0050] Preparation of porous silicon...

Embodiment 3

[0057] Preparation of silicon aluminum alloy:

[0058] 1) The phenolic resin powder, silicon dioxide powder, and alumina powder with a mass ratio of 10:0.5:2 are ball milled and mixed on a planetary ball mill to obtain a primary mixture. The ball milling conditions are: 350rpm, ball milling 10h, ball to material ratio 8:1.

[0059] 2) Put the primary mixture, NaCl, and KCl with a mass ratio of 1:5:4 in a boron nitride crucible, N 2 Under air protection, the temperature was raised to 800°C at 10°C / min, and kept for 1h. The product was washed with deionized water, filtered with suction, and dried in vacuum to obtain a silicon-aluminum alloy.

[0060] The X-ray diffraction pattern (XRD) of the silicon-aluminum alloy of above-mentioned preparation and in the embodiment figure 1 similar. It can be seen from the figure that no other phases are found except the two phases of silicon and aluminum.

[0061] Preparation of porous silicon / carbon composite anode materials:

[0062] 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Charging capacity | aaaaa | aaaaa |

| Inverse capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com