High-solubility fermented soybean meal and preparation method thereof

A technology of fermented soybean meal and high solubility, which is applied in the fields of application, animal feed, animal feed, etc., can solve the problem of insufficient solubility of fermented products, and achieve the effect of reducing the molecular weight of protein

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] The invention provides a method for preparing fermented soybean meal with high solubility.

[0056] The method provided by the invention comprises:

[0057] i) adding water to the dried and / or undried desolvated soybean meal;

[0058] ii) inoculation of microbial strains in water-added soybean meal; and

[0059] iii) Fermentation at 25°C to 45°C to obtain fermented soybean meal; finished product processing.

[0060] In one embodiment of the present invention, the following step may be included before step ii): sterilizing the desolvated soybean meal. In the present invention, the sterilization method used is a conventional method used in the art, for example including but not limited to: heat sterilization (including but not limited to dry heat, wet heat and intermittent heating sterilization), radiation sterilization , Osmotic pressure sterilization and other sterilization methods. In one embodiment of the present invention, the sterilization method includes, but i...

Embodiment 1

[0104] Embodiment 1: strain preparation

[0105] Seed liquid preparation: Inject Bacillus subtilis, Saccharomyces cerevisiae and lactic acid bacteria into the seed medium of Bacillus subtilis, Saccharomyces cerevisiae and lactic acid bacteria respectively, and ferment at 150 rpm for 24 hours at 37°C to obtain Bacillus subtilis and Saccharomyces cerevisiae respectively and lactic acid bacteria seeds.

Embodiment 2

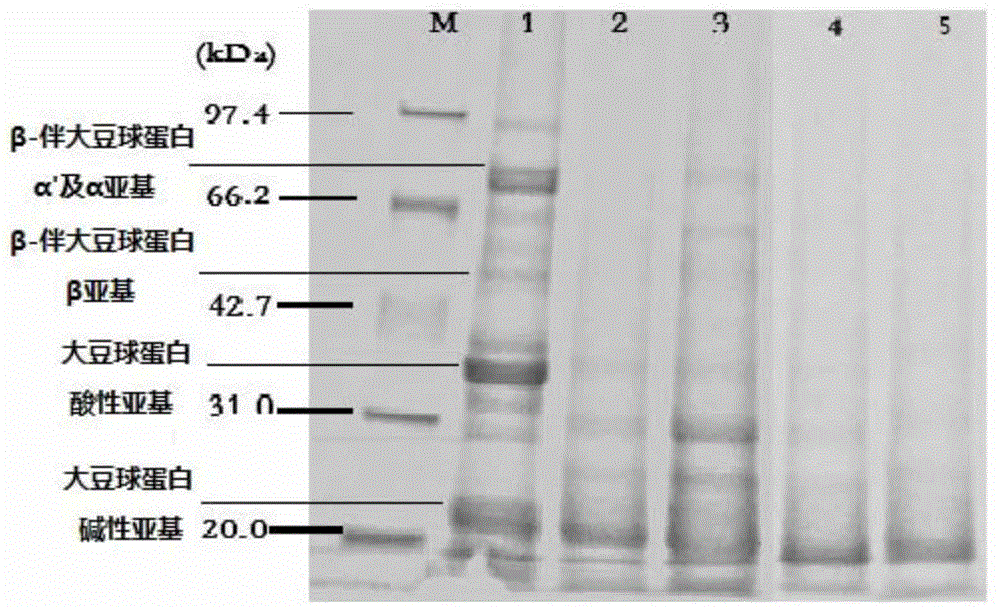

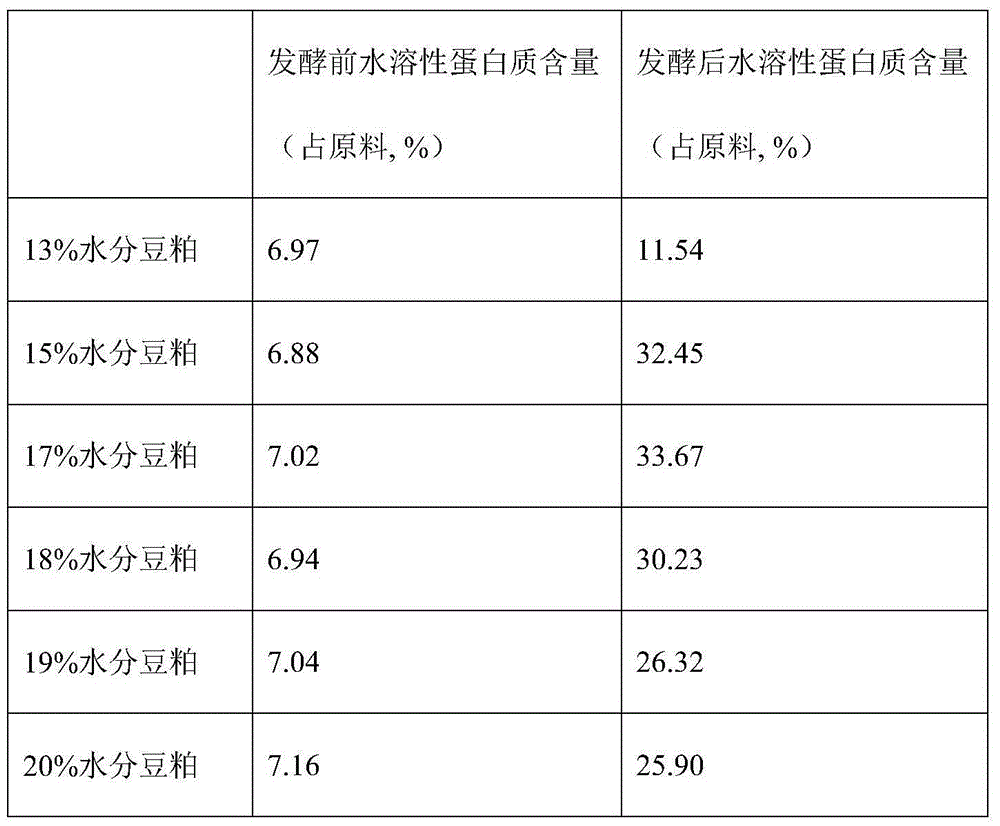

[0106] Example 2: Changes in quality and properties during fermentation of soybean meal mixed strains with 17% water content

[0107] The desolvated soybean meal is dried with hot air to reduce the moisture content to 17%, and steam sterilized at 121°C for 30 minutes. Add sterile water until the water content of the material (desolvated soybean meal) is 50%, and mix well.

[0108] Add mixed strains (70% of Bacillus subtilis, 20% of Saccharomyces cerevisiae and 10% of lactic acid bacteria) to the soybean meal with the inoculum amount of 10% of the weight of the wet soybean meal after adding water, and ferment at 25°C for 24 hours. The product was dried at 68-74°C for 2 hours until the moisture content was 12%. After the dried product was cooled to 30-40°C, it was crushed and passed through a 60-mesh sieve to obtain fermented soybean meal 1.

[0109] The water content, crude protein, water-soluble protein content, acid-soluble protein content, and pH of fermented soybean meal 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com