Preparation method of high-mechanical-strength SCR denitration catalyst

A denitrification catalyst, mechanical strength technology, applied in the direction of chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of short service life, unstable mechanical properties of catalysts, and low cost advanced questions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

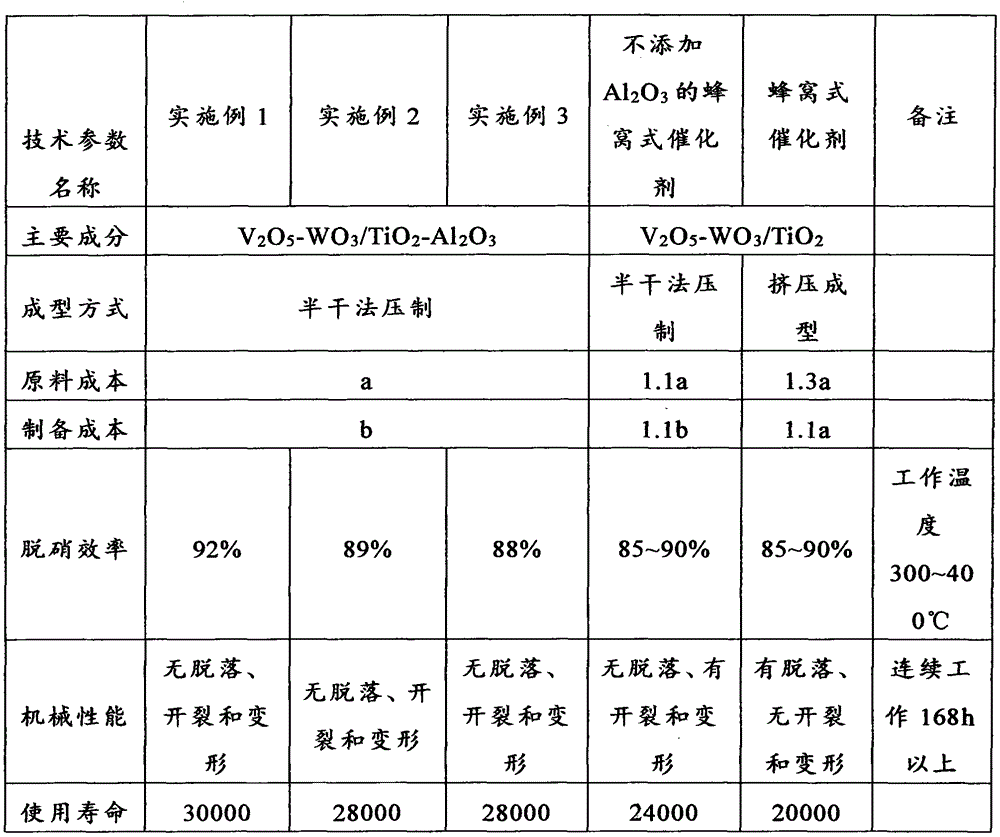

Examples

preparation example Construction

[0020] The embodiment of the present invention discloses a preparation method of a high mechanical strength SCR denitration catalyst, comprising the following steps: V 2 o 5 with WO 3 / TiO 2 -Al 2 o 3 The powder is mixed, stirred, roasted, and dried to obtain V 2 o 5 -WO 3 / TiO 2 -Al 2 o 3 ; to V 2 o 5 -WO 3 / TiO 2 -Al 2 o 3Add silica sol, methylcellulose, glass fiber filaments and ethanolamine to the mixture, stir to obtain a catalyst blank, add water and stir to obtain a slurry; add reinforced glass fiber carbon fiber composite board and the slurry to the semi-dry pressing mold in turn , pressing and molding to obtain a catalyst body; extruding the catalyst body into a honeycomb catalyst body, drying and calcining to obtain a high mechanical strength SCR denitration catalyst.

[0021] As a preferred option, the WO 3 / TiO 2 -Al 2 o 3 The powder is prepared as follows: add ammonium paratungstate to the oxalic acid solution, add Al after stirring 2 o 3 / Ti...

Embodiment 1

[0034] The described low-cost SCR denitration catalyst with high mechanical properties comprises the following steps:

[0035] 1. Preparation of composite carrier: at 2mol L -1 AlCl 3 solution, then add 2mol·L -1 TiCl 4 solution, the two solutions are mixed evenly and then slowly added dropwise with a concentration of 2mol L -1 ammonia water and stirred vigorously until the pH value reached 8. The precipitate was washed by centrifugation, and the filtered solid was dried and calcined at a constant temperature of 550°C for 4 hours to obtain Al 2 o 3 / TiO 2 Composite carrier.

[0036] 2. Preparation of catalyst blank: Dissolve 8g of oxalic acid in 160ml of distilled water to obtain an oxalic acid solution. Dissolve 18g of ammonium paratungstate in the oxalic acid solution and stir until completely dissolved. Al impregnation with ammonium paratungstate in an oil bath at 85 °C 2 o 3 / TiO 2 Composite carrier, stirring and evaporating to dryness. Dry in an oven at 100°C ...

Embodiment 2

[0041] The described low-cost SCR denitration catalyst with high mechanical properties comprises the following steps:

[0042] 1. Preparation of composite carrier: at 2mol L -1 AlCl 3 solution, then add 2mol·L -1 TiCl 4 solution, the two solutions are mixed evenly and then slowly added dropwise with a concentration of 2mol L -1 ammonia water and stirred vigorously until the pH value reached 8. The precipitate was washed by centrifugation, and the filtered solid was dried and calcined at a constant temperature of 550°C for 4 hours to obtain Al 2 o 3 / TiO 2 Composite carrier.

[0043] 2. Preparation of catalyst blank: Dissolve 7.5g of oxalic acid in 150ml of distilled water to obtain an oxalic acid solution. Dissolve 17.8g of ammonium paratungstate in the oxalic acid solution and stir until completely dissolved. Al impregnation with ammonium paratungstate in an oil bath at 85 °C 2 o 3 / TiO 2 Composite carrier, stirring and evaporating to dryness. Dry in an oven at 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com