Preparation method of catalyst for ozone oxidization

A technology of ozone oxidation and catalyst, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve problems such as shedding and loss, and achieve uniform distribution and high specific surface area Large, good catalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

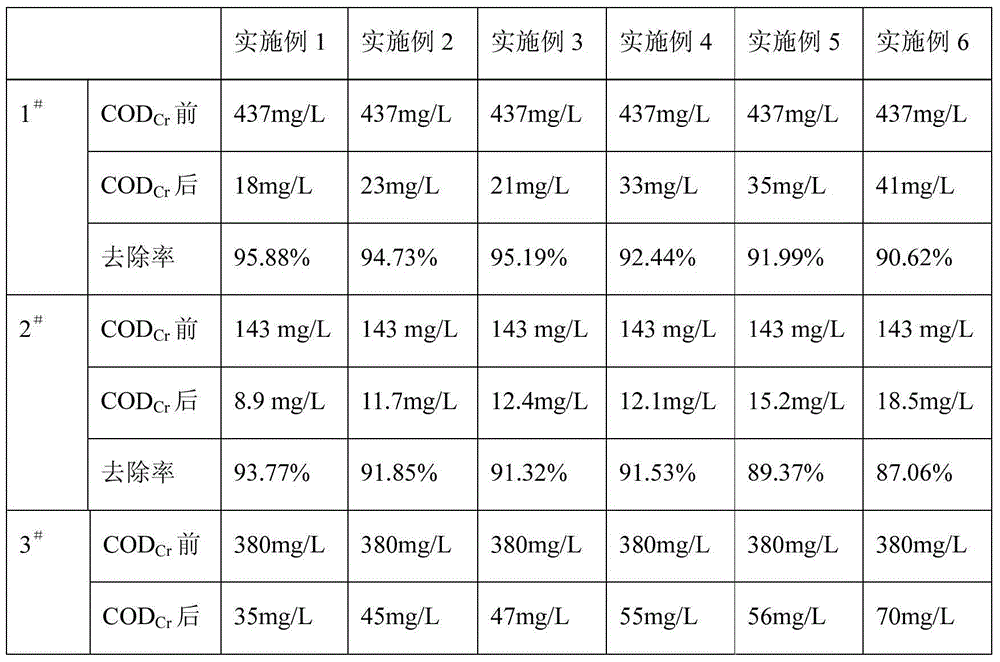

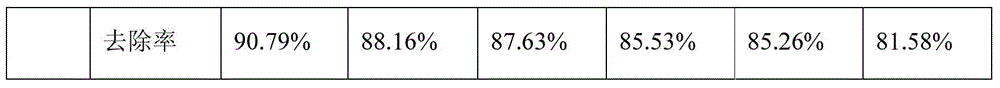

Examples

Embodiment 1

[0035]The specific surface area is 800~1200m 2 / g, the rod-shaped activated carbon with a particle size of 1.5-3 mm is used as a catalyst carrier, activated with 45% nitric acid at 60 ° C for 2 hours under reflux, then washed to neutral, and dried for later use.

[0036] Prepare a 10% mixed aqueous solution of ferric sulfate and manganese nitrate, wherein the molar ratio of iron to manganese is 5:1; the volume of the mixed aqueous solution of ferric sulfate and manganese nitrate is 1.5 times the volume of activated carbon. 10% ammonia water was used as precipitant.

[0037] The activated activated carbon is placed in a container, and under stirring, the pre-prepared iron salt, manganese salt mixed aqueous solution and ammonia water are added to the container for co-precipitation, wherein the iron salt, manganese salt mixed aqueous solution Adding speed is 3 ml / min, adjust the adding speed of ammonia water to ensure the pH value of the liquid in the container is 8-10, until th...

Embodiment 2

[0039] The specific surface area is 800~1200m 2 / g, the rod-shaped activated carbon with a particle size of 1.5-3 mm is used as a catalyst carrier, activated with 10% nitric acid under the condition of reflux for 4 hours at 80 ° C, then washed to neutral, and dried for later use.

[0040] Prepare a 15% mixed aqueous solution of ferric sulfate and manganese chloride, wherein the molar ratio of iron to manganese is 3:1; the volume of the mixed aqueous solution of ferric sulfate and manganese chloride is 1.5 times the volume of activated carbon. 15% ammonia water was used as precipitant.

[0041] The activated activated carbon is placed in a container, and under stirring, the pre-prepared iron salt, manganese salt mixed aqueous solution and ammonia water are added to the container for co-precipitation, wherein the iron salt, manganese salt mixed aqueous solution Adding speed is 6 ml / min, adjust the adding speed of ammonia water to ensure the pH value of the liquid in the contain...

Embodiment 3

[0043] The specific surface area is 800~1200m 2 / g, the rod-shaped activated carbon with a particle size of 1.5-3 mm is used as a catalyst carrier, activated by refluxing with 25% nitric acid for 3 hours at 70 ° C, then washed to neutral, and dried for later use.

[0044] Prepare a 20% mixed aqueous solution of ferric nitrate and manganese chloride, wherein the molar ratio of iron to manganese is 2:1; the volume of the mixed aqueous solution of ferric nitrate and manganese chloride is 1.5 times the volume of activated carbon. 20% ammonia water was used as precipitant.

[0045] The activated activated carbon is placed in a container, and under stirring, the pre-prepared iron salt, manganese salt mixed aqueous solution and ammonia water are added to the container for co-precipitation, wherein the iron salt, manganese salt mixed aqueous solution Adding speed is 10 ml / min, adjust the adding speed of ammonia water to ensure that the pH value of the liquid in the container is 10-12...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com