Manufacturing method for engine assembly type camshaft

A manufacturing method and camshaft technology, applied to cams, mechanical equipment, components with teeth, etc., can solve the problems of long processing procedures, low material utilization rate, high energy consumption, etc., and achieve the goal of reducing combination procedures and saving energy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

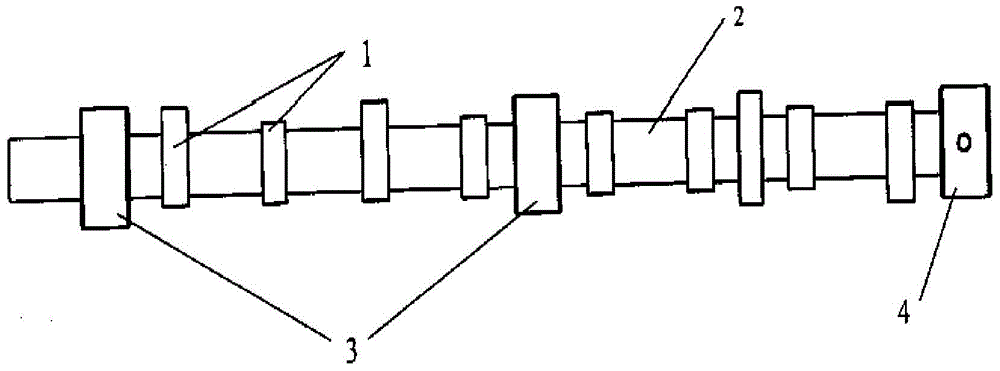

[0015] figure 1 Shown is a schematic diagram of the assembled camshaft of the 483 engine. The camshaft is assembled by brazing and powder metallurgy sintering welding. The specific steps are as follows:

[0016] (1) Selection of materials for each component: cam plate 1 is pressed by powder metallurgy materials; journal 3 and ends 4 are machined from steel parts; base shaft 2 is finished by seamless tube; The composition system of the cam piece is Fe-Cu-Cr-Mo-P-Si-C, wherein, according to the weight ratio, the Cu content is 0.5-3.0%, the Cr content is 3-8%, the Mo content is 0.5-5.0%, and the P The content is 0.3-0.7%, the Si content is 0.3-1.0%, the C content is 1.8-3.0%, and the Fe is the balance;

[0017] (2) The cam piece and the base shaft are assembled by powder metallurgy sintering welding process; the journal and both ends are assembled by brazing process with Cu as solder; among them, the high temperature sintering and brazing temperature is 1120 ° C, and the sinteri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com