A method for comprehensive utilization of magnesium slag

A magnesium slag and potassium carbonate technology, applied in the field of comprehensive utilization of waste resources, can solve the problems of restricting the large-scale application of magnesium reduction furnace slag, complex production process, unstable composition, etc., and achieve the restoration of heavy metal polluted soil, easy access to raw materials, The effect of process environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

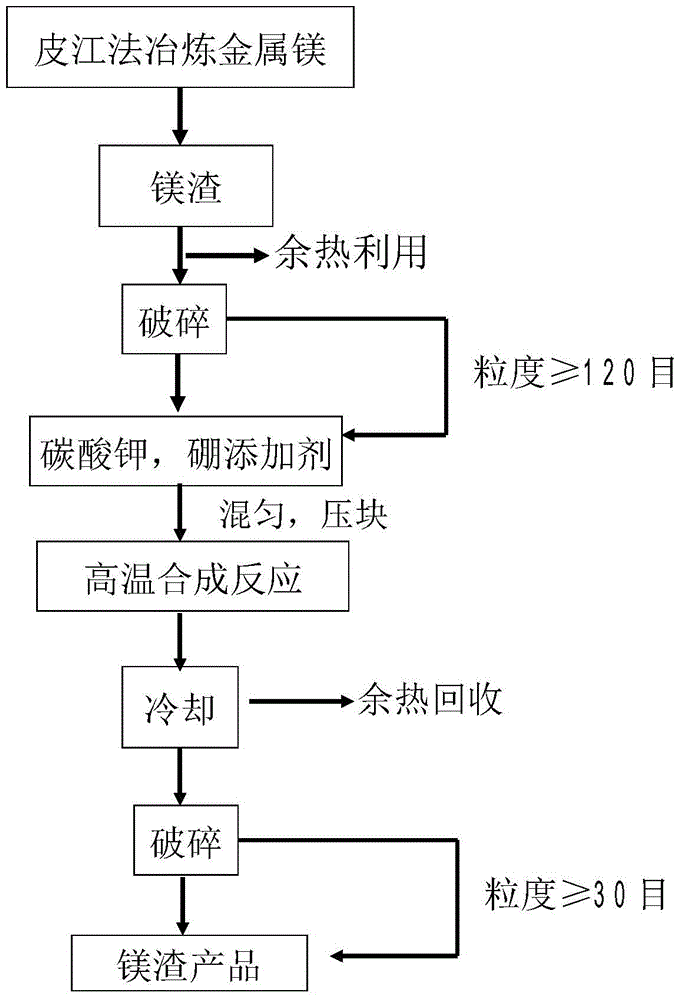

[0023] according to figure 1 In the process flow shown, the magnesium slag is ground to 120 mesh with a grinding machine, and the ingredients are: 65g of magnesium slag, 35g of potassium carbonate, 6g of boric acid, mix the magnesium slag, industrial potassium carbonate and boric acid, and put in corundum Put the corundum crucible into a temperature-controllable high-temperature electric furnace, heat up, the heating temperature is 1290 ° C, and the holding time is 40 minutes. After the heat preservation, the sample is cooled to room temperature by air. The sample is a relatively loose block. Grinding to 35 mesh, the obtained magnesium slag product is bagged and sealed.

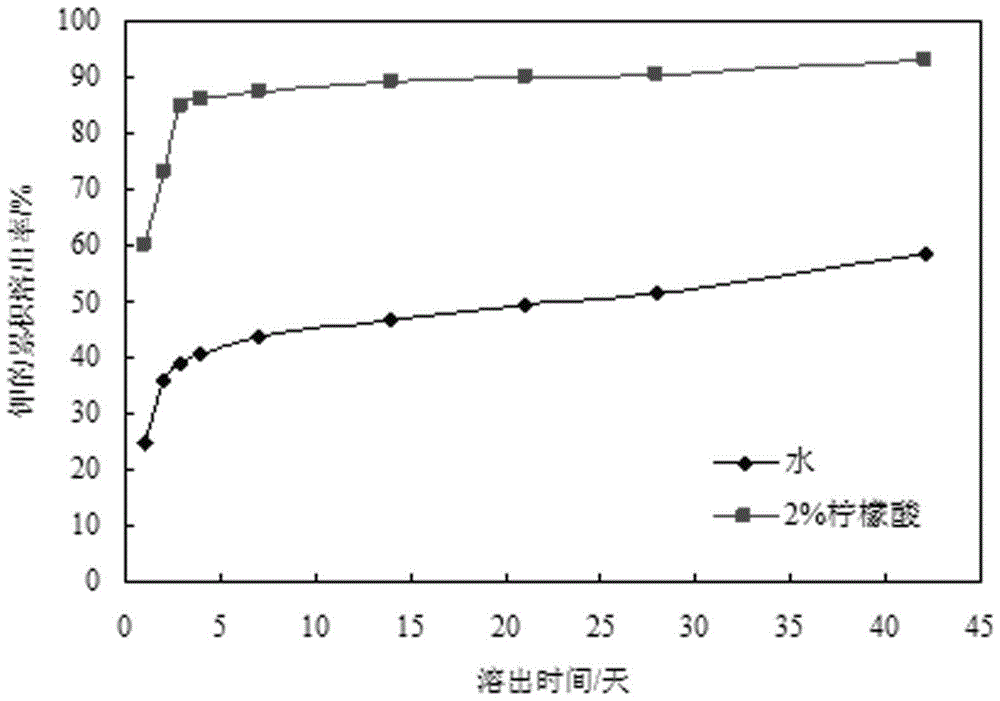

[0024] The magnesium slag product obtained through the above process has an effective silicon content of 11%, and its water-soluble initial dissolution rate and 28-day cumulative dissolution rate are respectively 27% and 52% through the slow-release fertilizer national standard method analysis, and the initia...

Embodiment 2

[0026] Grind the magnesium slag to 150 mesh with a pulverizer, and add the following ingredients: 70g of magnesium slag, 30g of potassium carbonate, and 7g of boric acid. Mix the magnesium slag, industrial potassium carbonate and boric acid, and put them into a corundum crucible; Put it in a temperature-controllable high-temperature electric furnace, heat up, the heating temperature is 1250 ° C, and the holding time is 60 minutes. After the heat preservation, the sample is cooled to room temperature by air. The sample is a relatively loose block, which is ground to 35 mesh. The vested magnesium slag products are bagged and sealed.

Embodiment 3

[0028] Grind the magnesium slag to 180 mesh with a pulverizer, and add the following ingredients: 75g of magnesium slag, 25g of potassium carbonate, 10g of borax, mix the magnesium slag and industrial potassium carbonate, and put them into a corundum crucible; put the corundum crucible into In a temperature-controllable high-temperature electric furnace, heat up, the heating temperature is 1200°C, and the holding time is 60 minutes. After the heat preservation, the sample is cooled to room temperature by air. Slag products, bagged and sealed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com