A tower type negative pressure continuous inert gas stripping naphthalene blowing method and its device

An inert gas and negative pressure technology, applied in the field of β-naphthalenesulfonic acid production, can solve the problems of difficult energy saving and emission reduction, clean production, production cost reduction, high energy consumption of naphthalene blowing, and meet the requirements of green production, The effect of small amount of public works and improvement of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

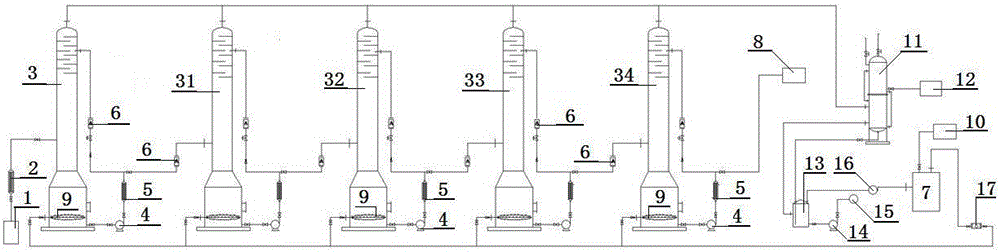

[0031] A, one-stage naphthalene-blowing: the hydrolyzate after the sulfonation reaction mixture is hydrolyzed in the hydrolysis reactor 1 enters the first-stage naphthalene-blowing tower 3 through the heat exchanger 2, and then the hydrolyzate passes through the bottom of the tower coordinated with the first-stage naphthalene-blowing tower 3 Circulating pump 4 and tower bottom reboiler 5 are sprayed into primary naphthalene blowing tower 3 again from the fifth tray of primary naphthalene blowing tower 3, and pure nitrogen is blown from inert gas storage tank 7 through compressor 17 from primary stage The bottom of the naphthalene tower 3 is in contact with the hydrolyzate in a countercurrent manner, and the naphthalene vapor and nitrogen overflow from the top of the primary naphthalene blowing tower 3 into the vaporization condensation cooler 11, and the liquid phase naphthalene and nitrogen gas are sent from the vaporization condensation cooler 11 to the gas-liquid separator 1...

Embodiment 2

[0038] A, one-stage naphthalene-blowing: the hydrolyzate after the sulfonation reaction mixture is hydrolyzed in the hydrolysis reactor 1 enters the first-stage naphthalene-blowing tower 3 through the heat exchanger 2, and then the hydrolyzate passes through the bottom of the tower coordinated with the first-stage naphthalene-blowing tower 3 Circulating pump 4 and tower bottom reboiler 5 are sprayed into primary naphthalene blowing tower 3 again from the fifth tray of primary naphthalene blowing tower 3, and pure nitrogen is blown from inert gas storage tank 7 through compressor 17 from primary stage The bottom of the naphthalene tower 3 is in contact with the hydrolyzate in a countercurrent manner, and the naphthalene vapor and nitrogen overflow from the top of the primary naphthalene blowing tower 3 into the vaporization condensation cooler 11, and the liquid phase naphthalene and nitrogen gas are sent from the vaporization condensation cooler 11 to the gas-liquid separator 1...

Embodiment 3

[0045] A, one-stage naphthalene-blowing: the hydrolyzate after the sulfonation reaction mixture is hydrolyzed in the hydrolysis reactor 1 enters the first-stage naphthalene-blowing tower 3 through the heat exchanger 2, and then the hydrolyzate passes through the bottom of the tower coordinated with the first-stage naphthalene-blowing tower 3 Circulating pump 4 and tower bottom reboiler 5 are sprayed into primary naphthalene blowing tower 3 again from the fifth tray of primary naphthalene blowing tower 3, and pure nitrogen is blown from inert gas storage tank 7 through compressor 17 from primary stage The bottom of the naphthalene tower 3 is in contact with the hydrolyzate in a countercurrent manner, and the naphthalene vapor and nitrogen overflow from the top of the primary naphthalene blowing tower 3 into the vaporization condensation cooler 11, and the liquid phase naphthalene and nitrogen gas are sent from the vaporization condensation cooler 11 to the gas-liquid separator 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com