Method for preparing conductive polyaniline/graphene large-area flexible electrochromic material

A conductive polyaniline and graphene technology, which is applied in the electrolysis process, electrolysis components, electrolysis organic production, etc., to achieve the effects of good adhesion, stable performance and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The preparation method of conductive polyaniline / graphene large-area flexible electrochromic material comprises the following steps:

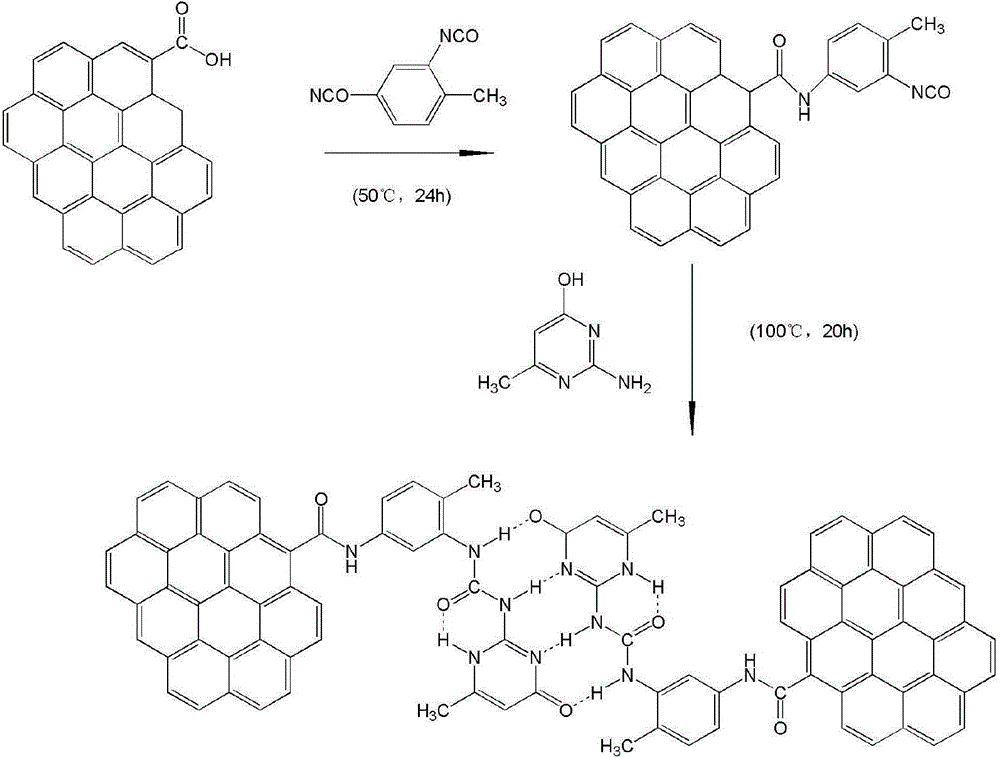

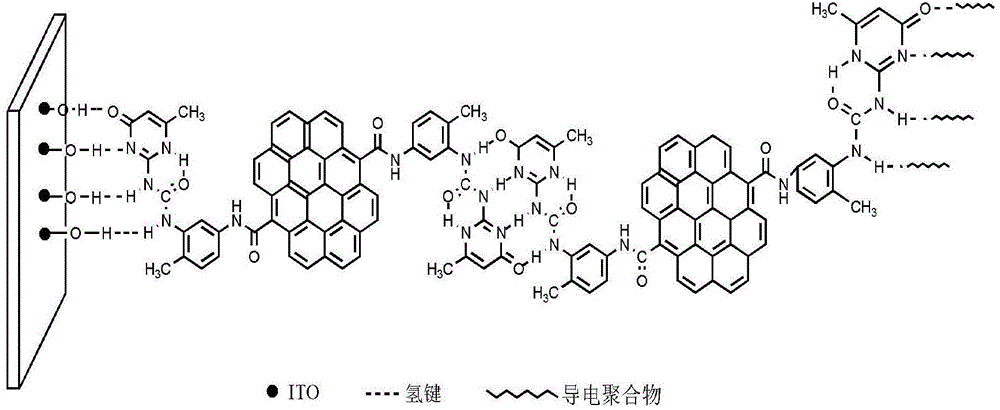

[0023] 1) Under the protection of an inert gas, disperse graphene containing 2g of carboxyl groups in 800g of dimethylformamide and ultrasonically disperse in a water bath for 1h, then add 4g of toluene diisocyanate and heat at 50°C for 24h to generate a coupling reaction to introduce isocyanide Acid groups, unreacted toluene diisocyanate were removed by washing and vacuum filtration.

[0024]2) 2 g of graphene modified by the obtained isocyanate group was dispersed in 800 g of dimethylformamide solution, and 4 g of 4-amino-6-hydroxyl-2-methylpyrimidine and 2 g of triethyl acetic acid were added salt to obtain 2-ureido-4[1H]-pyrimidinone group, the mixture was ultrasonically stirred at 100°C for 20 h, washed and dried, then dissolved in an organic solvent to obtain a dispersion solution of graphene bonded by four hydrogen bonds.

[0025...

Embodiment 2

[0027] The preparation method of conductive polyaniline / graphene large-area flexible electrochromic material comprises the following steps:

[0028] 1) Under the protection of an inert gas, disperse graphene containing 10g of carboxyl groups in 5000g of dimethylformamide and ultrasonically disperse in a water bath for 1h, then add 50g of toluene diisocyanate and heat at 50°C for 24h to generate a coupling reaction to introduce isocyanide Acid groups, unreacted toluene diisocyanate were removed by washing and vacuum filtration.

[0029] 2) 10g of graphene modified by the obtained isocyanate group was dispersed in 5000g of dimethylformamide solution, and 30g of 4-amino-6-hydroxyl-2-methylpyrimidine and 20g of triethyl acetic acid were added salt to obtain 2-ureido-4[1H]-pyrimidinone group, the mixture was ultrasonically stirred at 100°C for 20 h, washed and dried, then dissolved in an organic solvent to obtain a dispersion solution of graphene bonded by four hydrogen bonds.

[...

Embodiment 3

[0032] The preparation method of conductive polyaniline / graphene large-area flexible electrochromic material comprises the following steps:

[0033] 1) Under the protection of an inert gas, disperse graphene containing 50g of carboxyl groups in 15,000g of dimethylformamide in a water bath and ultrasonically disperse for 1h, then add 100g of toluene diisocyanate and heat at 50°C for 24h to generate a coupling reaction to introduce isocyanide Acid groups, unreacted toluene diisocyanate were removed by washing and vacuum filtration.

[0034] 2) 50g of graphene modified by the obtained isocyanate group was dispersed in 15000g of dimethylformamide solution, and 150g of 4-amino-6-hydroxyl-2-methylpyrimidine and 100g of triethyl acetic acid were added salt to obtain 2-ureido-4[1H]-pyrimidinone group, the mixture was ultrasonically stirred at 100°C for 20 h, washed and dried, then dissolved in an organic solvent to obtain a dispersion solution of graphene bonded by four hydrogen bonds...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com