Quantum well structure of photoelectric device

A photoelectric device and quantum well technology, which is applied in the field of quantum well structure, can solve the problems that holes cannot be injected effectively, hole migration rate is blocked, and electrons in the N layer are easy to migrate, so as to achieve quantum confinement with weakened Stark effect and electron Effects of improved blocking efficiency and increased hole injection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

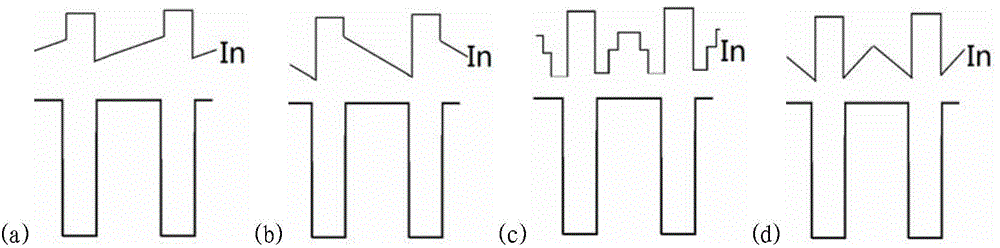

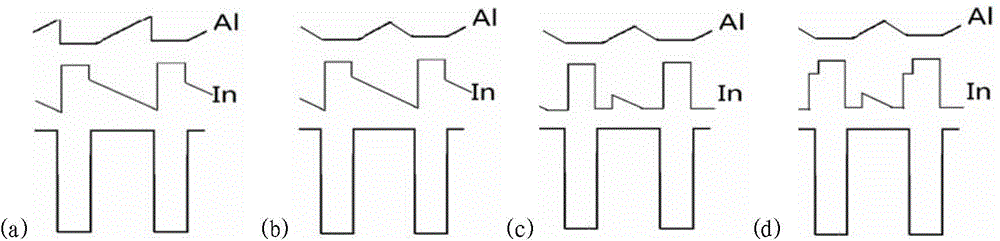

[0027] Low power high brightness chip design under low current. Can be designed as figure 1 In the structure shown in (a), the distribution of In components in each barrier layer increases linearly and gradually, and the proportion of In in the barrier layer gradually changes from X to Y, where X is 0.1% and Y is 5%.

[0028] It has been verified that the brightness of the structure adopting the gradual change of the In composition of the barrier layer is 20%-30% higher than that of the traditional structure.

Embodiment 2

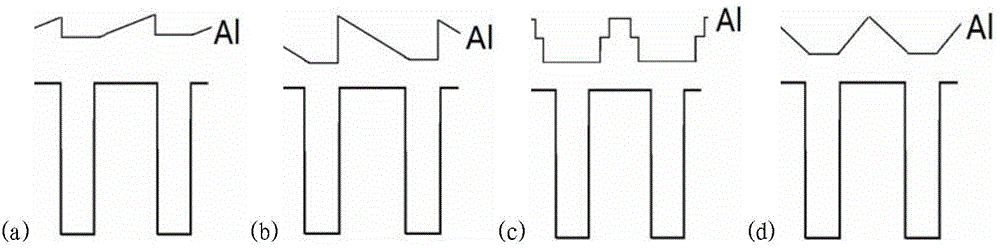

[0030] Low power high brightness chip design under high current. All barriers can be designed as figure 1 The structure shown in (a) combined with the design of the Al composition of the last two barrier layers is designed as figure 2 (a), the distribution of In components in each barrier layer increases linearly and gradually, and the proportion of In in this barrier layer gradually changes from X to Y, where X is 0.1%, Y is 5%, and the last two barrier layers The distribution of the inner Al component increases linearly and gradually, and the proportion of the Al component in the barrier layer changes gradually from M to N, where M is 0.1% and N is 5%.

[0031] It has been verified that the brightness of the structure using the gradual change of the In composition of the barrier layer combined with the gradual change of the Al composition of the last two barrier layers is 13% higher than that of the traditional structure, and the maximum current value that can be passed is...

Embodiment 3

[0033] The design of medium power and high brightness chip under high current. All barriers can be designed as figure 1 The structure shown in (a) combined with the design of the Al composition except the last 2 barrier layers is designed as figure 2 (c), the Al composition of the last two barrier layers is designed as figure 2 (d), the distribution of In components in each barrier layer increases linearly and gradually, and the proportion of In in this barrier layer gradually changes from X to Y, where X is 0.1%, and Y is 5%; except the last two barriers The Al composition outside the layer gradually changes in a trapezoidal manner, the Al content of the high Al composition position is 3.5%, and the Al content of the low Al composition position is 1.5%; the distribution of the Al composition in the last two barrier layers increases linearly and gradually. The proportion of Al components in the layer is gradually changed from M to N, where M is 0.1% and N is 3.5%.

[0034...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com