Organic light emitting device and manufacturing method thereof

An electroluminescent device and luminescent technology, which is applied in the direction of electric solid-state devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problem of low luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

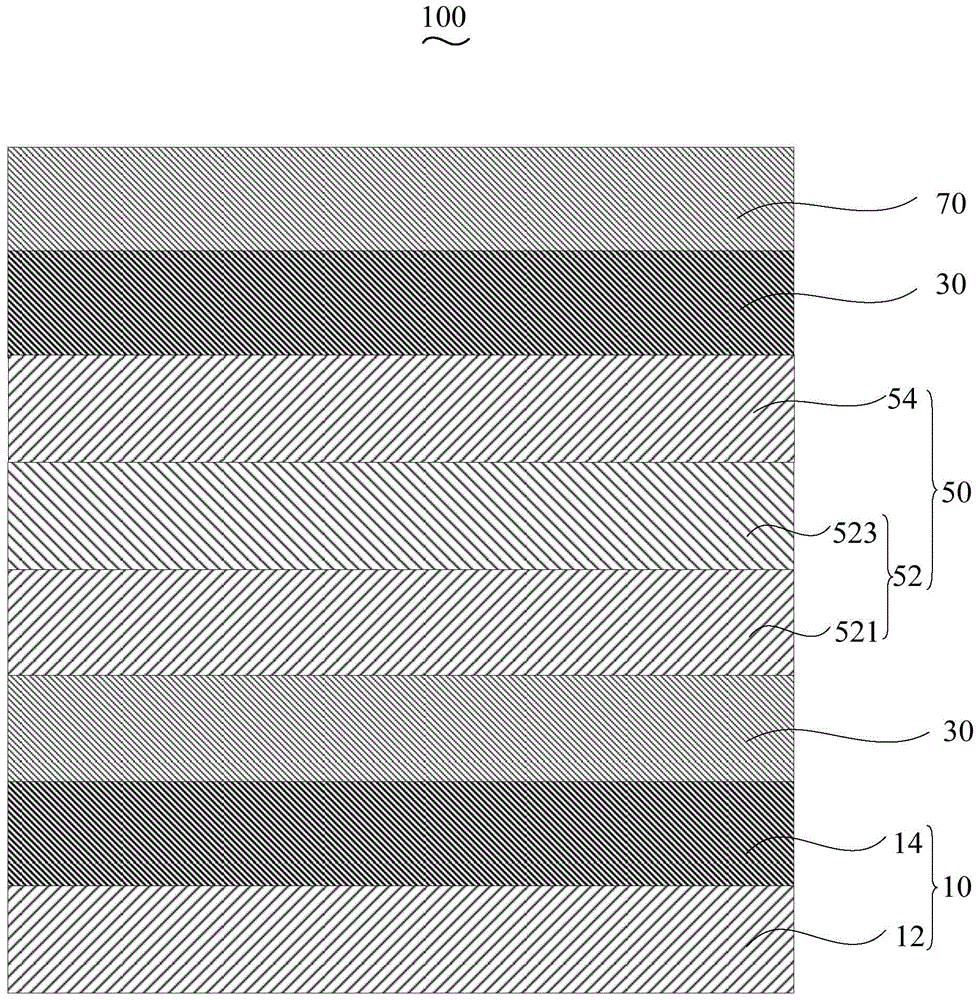

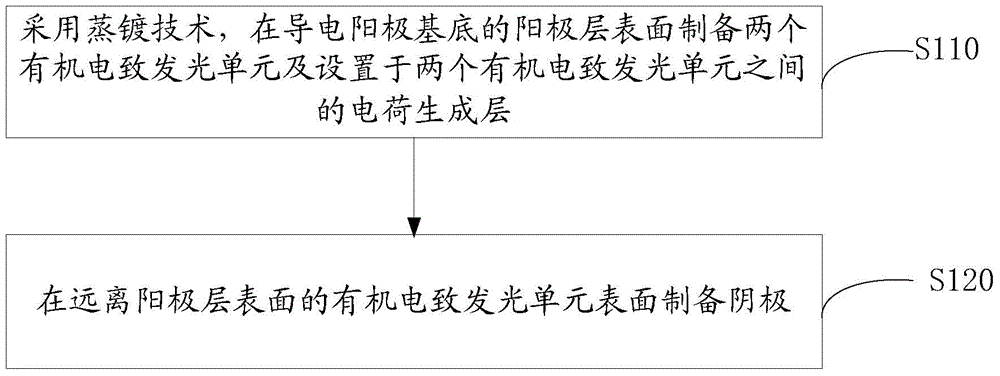

[0042] Please also see figure 2 , the preparation method of the organic electroluminescent device 100 of one embodiment, it comprises the following steps:

[0043] Step S110 , preparing two organic electroluminescent units 30 and a charge generation layer 50 disposed between the two organic electroluminescent units 30 on the surface of the anode layer 14 of the conductive anode substrate 10 using evaporation technology.

[0044] The conductive anode substrate 10 includes a transparent substrate 12 and an anode layer 14 prepared on the transparent substrate 12 . Preferably, the transparent substrate 12 is glass. The material of the anode layer 14 is indium tin oxide (ITO). The sheet resistance of the anode layer 14 is 5-100Ω / sq.

[0045] Preferably, before the conductive anode substrate 10 is used, a step of cleaning the conductive anode substrate 10 is also included. The cleaning steps are as follows: the base of the conductive anode is ultrasonically cleaned with deterge...

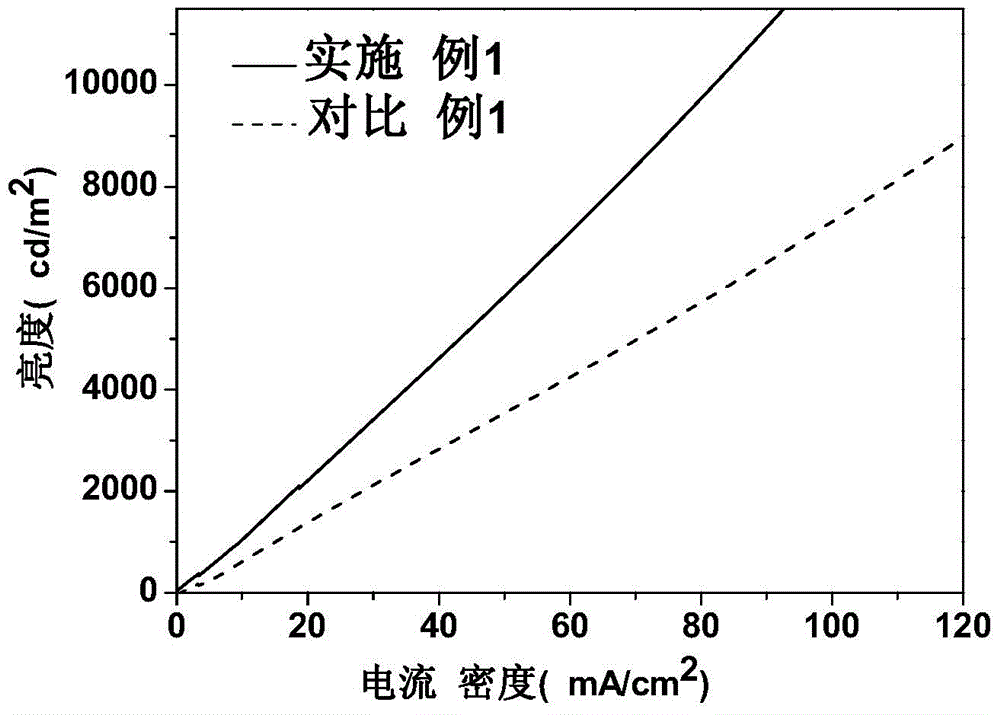

Embodiment 1

[0075] The structure prepared in this example is ITO glass / NPB / NPB: Ir(MDQ)2(acac) / Bphen / Li 2 CO 3 : Organic electroluminescent device of Bphen / ZnO / HAT-CN / m-MTDATA / CBP: FIr6 / Bphen / Mg-Al. Among them, the slash " / " indicates a layered structure, and the colon ":" indicates doping, the same below.

[0076] The preparation of the organic electroluminescent device of this embodiment comprises the following steps:

[0077] The conductive substrate is provided as the anode, and cleaned, it is ITO conductive glass, and the sheet resistance is 5Ω / □.

[0078] In a vacuum of 1 x 10- 5 In Pa's vacuum coating system, a hole transport layer is prepared on the surface of the ITO conductive film, the material is NPB, the thickness is 20nm, and the evaporation rate of NPB is 0.1nm / s.

[0079] In a vacuum of 1×10 -5 In the vacuum coating system of Pa, the light-emitting layer is prepared on the surface of the hole transport layer by thermal resistance evaporation technology, and the materi...

Embodiment 2

[0089] The structure prepared in this example is ITO glass / MeO-TPD / DCJTB:Alq3 / TPBi / Cs 2 CO 3 : TPBi / SnO 2 / HAT-CN / MeO-TPD / DPVBi / TPBi / Al organic electroluminescent devices.

[0090] The preparation of the organic electroluminescent device of this embodiment comprises the following steps:

[0091] The conductive substrate is provided as the anode, and cleaned, it is ITO conductive glass, and the sheet resistance is 100Ω / □.

[0092] In a vacuum of 1 x 10- 3 In the vacuum coating system of Pa, a hole transport layer is prepared on the surface of the ITO film, the material is MeO-TPD, the thickness is 80nm, and the evaporation rate of MeO-TPD is 1nm / s.

[0093] In a vacuum of 1 x 10- 3 In the vacuum coating system of Pa, the light-emitting layer is prepared on the surface of the hole transport layer by thermal resistance evaporation technology. The material of the light-emitting layer is a mixture of DCJTB and Alq3. The mass ratio of DCJTB to Alq3 is 5:100. The evaporation rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com