Concentration method of milk and preparation method of dairy products

A technology for dairy products and milk, applied in the direction of dairy products, milk preparations, and other dairy products, can solve the problems of high concentration temperature, high energy consumption, and inability to retain the flavor and nutrition of milk well.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

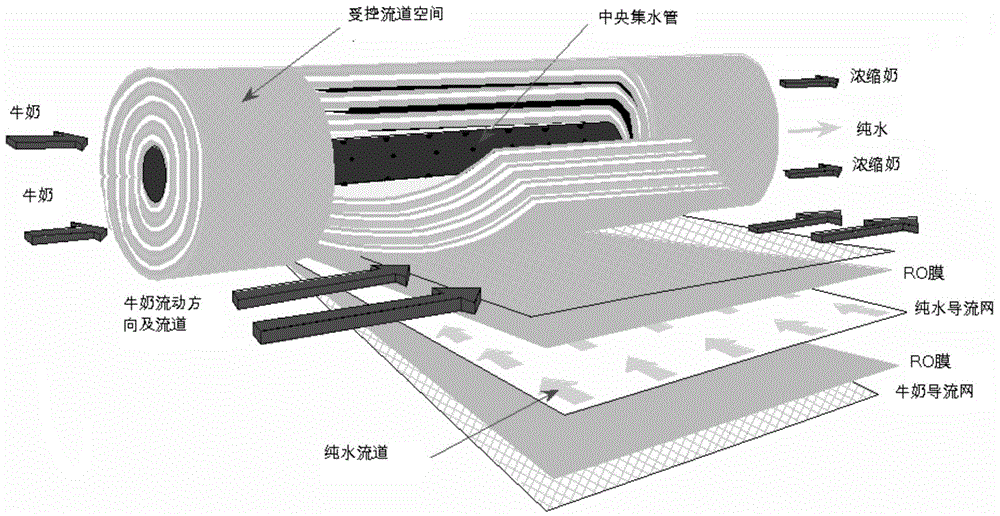

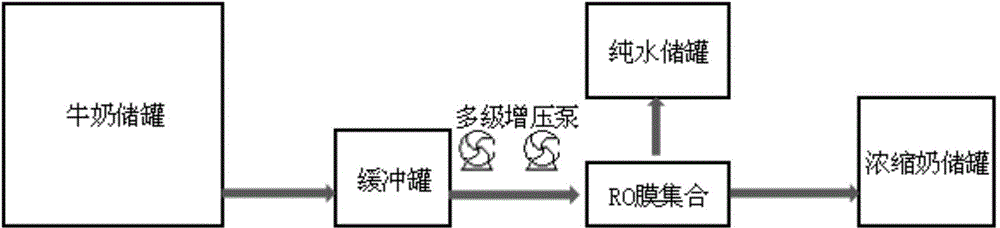

Method used

Image

Examples

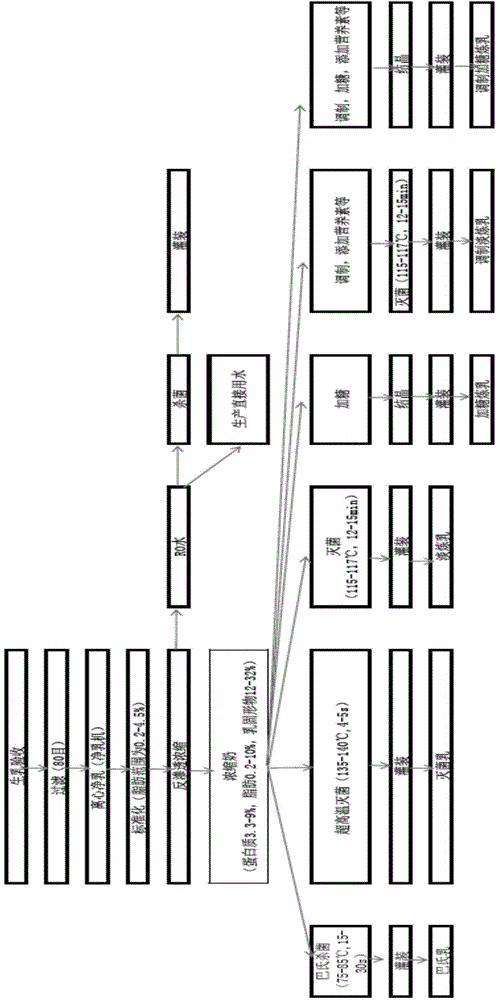

Embodiment 1

[0038] The raw milk has been tested, and the protein is ≥2.8% and the fat is ≥3.1%. After being processed by the milk purifier, it enters the standardized equipment, and the fat range is controlled to (0.2%-4.5%) according to the requirements of the finished product to obtain standardized milk. Content ≥ 3.3%) milk, concentrated milk with a fat range of 0.2%-4.5%, the concentrated milk is then passed through a pasteurizer to obtain pasteurized milk stored in a cold chain, and packaged and sold according to different packaging specifications.

Embodiment 2

[0040] The raw milk has been tested, and the protein is ≥2.8% and the fat is ≥3.1%. After being processed by the milk purifier, it enters the standardized equipment, and the fat range is controlled to (0.2%-4.5%) according to the requirements of the finished product to obtain standardized milk. Content ≥ 3.3%) milk, concentrated milk with a fat range of 0.2%-4.5%, the concentrated milk is then passed through an ultra-high temperature sterilizer to obtain sterilized milk that can be stored at room temperature, and packaged and sold according to different packaging requirements.

Embodiment 3

[0042] The raw milk has been tested, and the protein is ≥2.8% and the fat is ≥3.1%. After being processed by the milk purifier, it enters the standardized equipment, and the fat range is controlled to (0.2%-4.5%) according to the requirements of the finished product to obtain standardized milk, and then the standardized milk enters the reverse osmosis membrane treatment system to obtain evaporated milk with milk solids content ≥ 25%. , according to different packaging specifications for filling and sales.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com