Diamond tool bit and preparation method thereof

A diamond cutter head and diamond technology, applied in the field of materials, can solve the problems of high production cost, high energy consumption, and long sintering time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

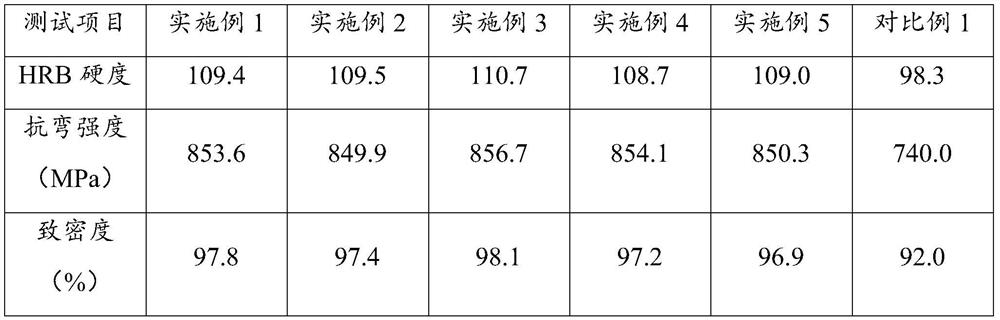

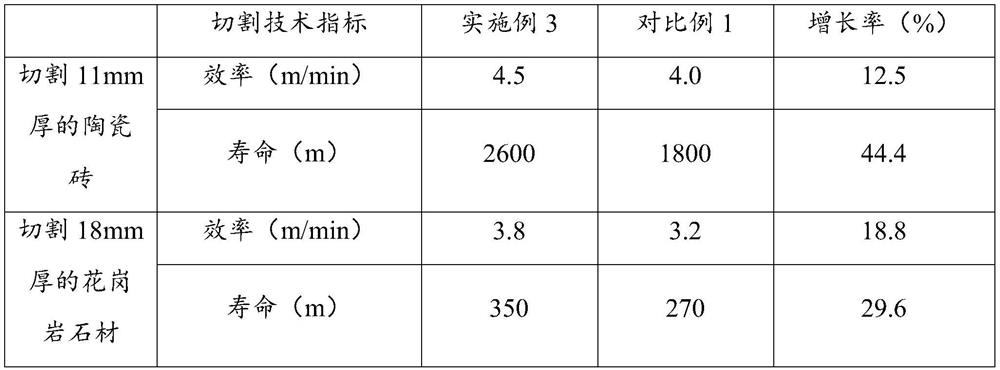

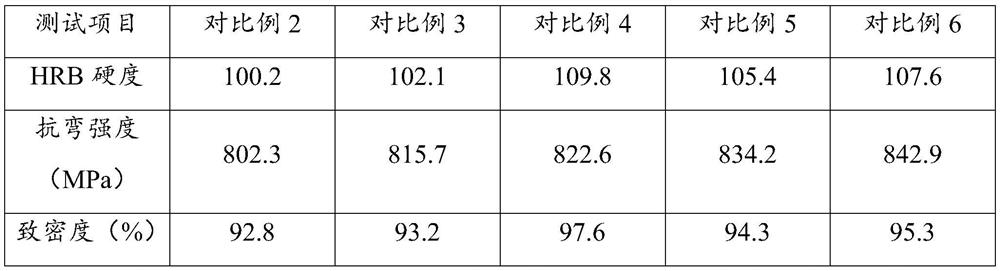

Examples

preparation example Construction

[0011] The preparation method of the diamond segment provided by the embodiment of the present invention adopts the method of discharge plasma sintering for sintering, the sintering time is short, the heating is uniform, the temperature field is relatively small, and the energy consumption is low, which can inhibit the grain coarsening and prevent the secondary heavy Crystallization, the structure is fine and uniform, can maintain the natural state of the raw material, can greatly improve the holding force of the metal bond on the diamond, and improve the sharpness, wear resistance and density of the diamond cutter head, and can maintain the quality of mass production Product quality stability. Compared with the traditional hot-pressing sintering process, its efficiency is increased by at least 50%, energy consumption is reduced by more than 80%, and it does not produce waste gas and waste residue, which is environmentally friendly, and can reduce labor intensity and save produ...

Embodiment 1

[0026] The diamond cutter bit of the present embodiment is prepared by the following steps:

[0027] Put the atomized iron-copper-nickel alloy powder (350 mesh), electrolytic copper powder (450 mesh), tin powder (150 mesh) and tungsten carbide (2800 mesh) according to the mass ratio of 30:20:8:10 Put it into a planetary ball mill, and at a rotating speed of 150r / min, the reverse frequency is 20Hz, continuous ball milling for 15min, and then sealing and vacuumizing for 20min to obtain a premix; after taking out the premix, put it into a three-dimensional mixer, Add diamond and mix for 2 hours to get mixed powder (the mass ratio of diamond, atomized iron-copper-nickel alloy powder, electrolytic copper powder, tin powder and tungsten carbide in the system is 3:30:20:8:10) Put the mixed powder into a graphite mold, place it in a discharge plasma sintering machine, fill it with an inert gas after vacuuming, and carry out sintering treatment at a temperature of 850°C and a pressure ...

Embodiment 2

[0029]Put the atomized iron-copper-nickel alloy powder (400 mesh), electrolytic copper powder (500 mesh), tin powder (200 mesh) and tungsten carbide (3000 mesh) according to the mass ratio of 40:25:10:15 Put it into a planetary ball mill, at a rotating speed of 250r / min, a reverse frequency of 25Hz, continue ball milling for 20min, and then seal and vacuumize for 30min to obtain a premix; after taking out the premix, put it into a three-dimensional mixer, Add diamond and mix for 3 hours to obtain mixed powder (the mass ratio of diamond, atomized iron-copper-nickel alloy powder, electrolytic copper powder, tin powder and tungsten carbide in the system is 5:40:25:10:15) ; Put the mixed powder into a graphite mold, then place it in a discharge plasma sintering machine, fill it with inert gas after vacuuming, and carry out sintering treatment at a temperature of 800°C and a pressure of 35MPa for 3 minutes, and then keep warm 2min, take it out and grind it after cooling to get the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com