Two-component microporous film with waterproof, moisture-permeable and high elastic properties

A microporous film, waterproof and moisture-permeable technology, applied in the field of textile fabrics, can solve the problems of not being able to adapt to film damage well, waterproof performance and adhesive performance decline, etc., to improve the performance of preventing rainwater, improve elasticity and adaptability, reduce The effect of moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

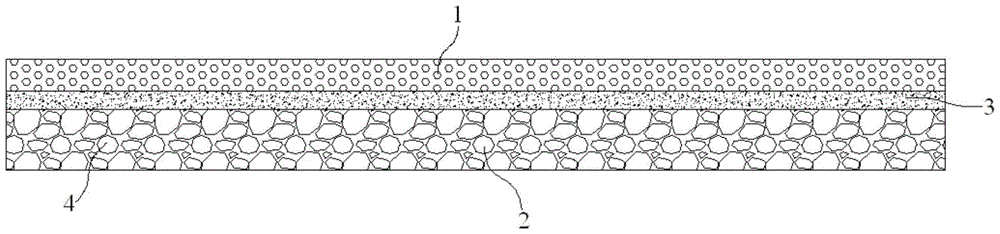

[0031] Embodiment 1: A two-component microporous film with waterproof, moisture-permeable and high elastic properties, comprising a microporous polyurethane film 1, a polytetrafluoroethylene film 2, the microporous polyurethane film 1, a polytetrafluoroethylene film 2 are bonded by an adhesive layer 3, and the number of holes 4 per square inch of the polytetrafluoroethylene film 2 is 8.5 to 9.5 billion, and the average diameter of the holes 4 is 0.2um to 10um;

[0032] The microporous polyurethane film 1 is obtained by scraping and coating prefabricated polyurethane slurry on silicone oil release paper and sequentially baking in an oven with a temperature gradient of 80 to 150 degrees, and then cooling to normal temperature after reaching 150 degrees and keeping warm;

[0033] The prefabricated polyurethane slurry consists of the following components:

[0034] 100 parts of polyurethane resin,

[0035] 22 parts of dimethylformamide,

[0036] 32 parts of toluene,

[0037] But...

Embodiment 2

[0051] Embodiment 2: A two-component microporous film with waterproof, moisture-permeable and high elastic properties, comprising a microporous polyurethane film 1, a polytetrafluoroethylene film 2, and the microporous polyurethane film 1, a polytetrafluoroethylene film 2 are bonded by an adhesive layer 3, and the number of holes 4 per square inch of the polytetrafluoroethylene film 2 is 8.5 to 9.5 billion, and the average diameter of the holes 4 is 0.2um to 10um;

[0052] The microporous polyurethane film 1 is obtained by scraping and coating prefabricated polyurethane slurry on silicone oil release paper and sequentially baking in an oven with a temperature gradient of 80 to 150 degrees, and then cooling to normal temperature after reaching 150 degrees and keeping warm;

[0053] The prefabricated polyurethane slurry consists of the following components:

[0054] 100 parts of polyurethane resin,

[0055] 25 parts of dimethylformamide,

[0056] 35 parts of toluene,

[0057]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com