Nanosheet self-assembled SAPO-34 molecular sieve and preparation method thereof

A SAPO-34, self-assembly technology, applied in the chemical field, can solve problems such as complex processes, and achieve the effects of high acid content, large specific surface area, and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

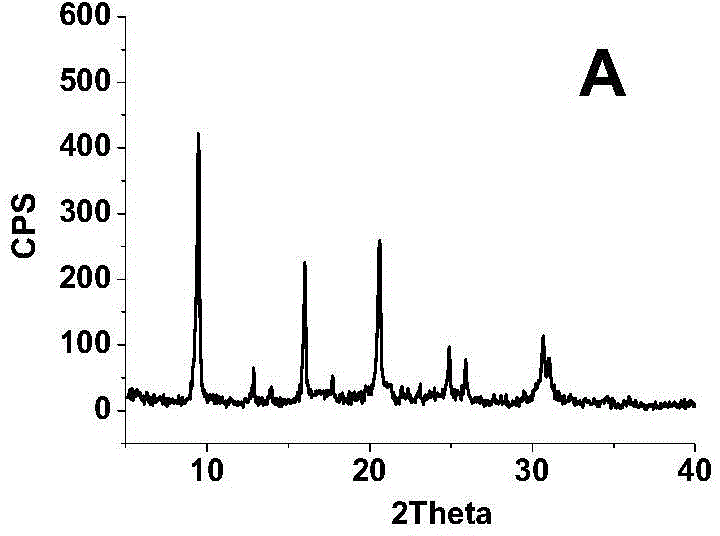

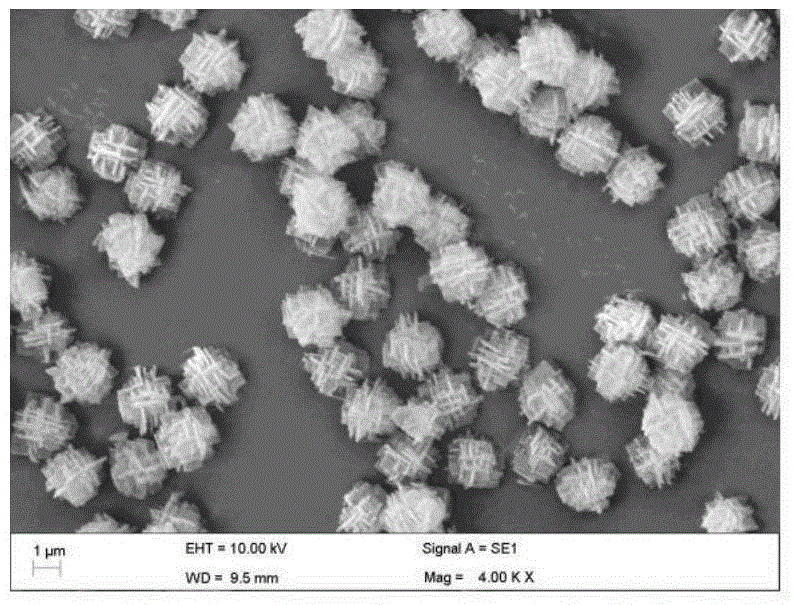

[0038] 284.4g of aluminum isopropoxide (Al 2 o 3 content is 26.3%) into 786g deionized water, add 414.5g morpholine and 40.8gTMAmOH (TMAmOH content is 25%), stir for 5h, add 70.6g ethyl orthosilicate (SiO 2 Content is 40%), 183.0g orthophosphoric acid (H 3 PO 4 content is 85%) and 68.3g of n-hexane, stirred for 3h to obtain a gel, transferred the gel to a crystallization kettle, and crystallized at 185°C for 48h to obtain a mixed solution, filtered the mixed solution to obtain a filter cake, and washed the filter cake until The pH value of the filtrate was less than 8, dried at 80-120°C for 8 hours, programmed to heat up to 550°C at a heating rate of 3°C / min, and roasted for 6 hours to obtain the target product, which was named A. After XRD and SEM characterization tests, it is found that the product A prepared under this condition has a typical CHA type diffraction peak of SAPO-34, such as figure 1 As shown, the SEM picture shows that the product is a spherical particle f...

Embodiment 2

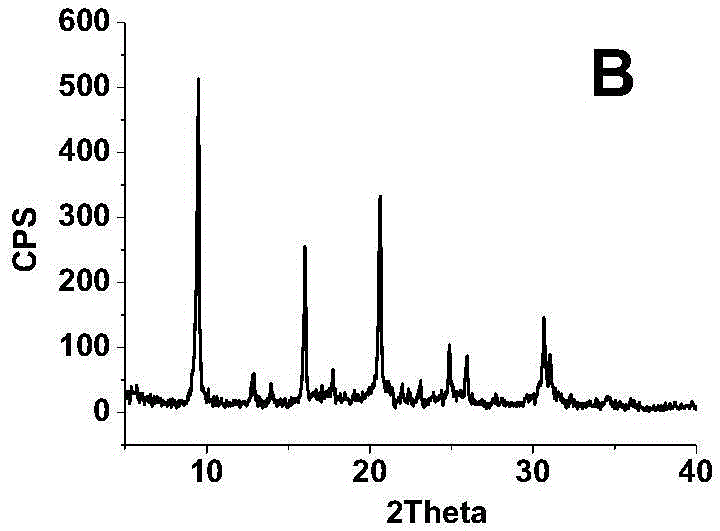

[0040] 284.4g of aluminum isopropoxide (Al 2 o 3 Content is 26.3%) into 768.3g deionized water, add 345.6g morpholine and 30.6gTMAmOH (TMAmOH content is 25%), stir for 5h, add 70.6g ethyl orthosilicate (SiO 2 Content is 40%), 183.0g orthophosphoric acid (H 3 PO 4content is 85%), stirred for 3 hours to obtain a gel, transferred the gel to a crystallization kettle, and crystallized at 195°C for 48 hours to obtain a mixed solution, filtered the mixed solution to obtain a filter cake, washed the filter cake until the pH value of the filtrate was less than 8. Dry at 80-120°C for 8 hours, program the temperature up to 550°C at a heating rate of 3°C / min, and roast for 6 hours to obtain the target product, named B. After XRD and SEM characterization tests, it is found that the product B prepared under this condition has a typical CHA type diffraction peak of SAPO-34, such as image 3 As shown, the SEM picture shows that the product is a spherical particle formed by the self-assemb...

Embodiment 3

[0042] 284.4g of aluminum isopropoxide (Al 2 o 3 Content is 26.3%) into 809.0g deionized water, add 276.4g morpholine and 27.2gTMAmOH (TMAmOH content is 25%), stir for 3h, add 70.6g ethyl orthosilicate (SiO 2 Content is 40%), 183.0g orthophosphoric acid (H 3 PO 4 content is 85%) and 76.2g of toluene, stirred for 1h to obtain a gel, transferred the gel to a crystallization kettle, and crystallized at 165°C for 24h to obtain a mixed solution, filtered the mixed solution to obtain a filter cake, washed the filter cake to the filtrate The pH value is less than 8, dried at 80-120°C for 8 hours, programmed to heat up to 600°C at a heating rate of 3°C / min, and roasted for 5 hours to obtain the target product, named C. After XRD and SEM characterization tests, it was found that the product C prepared under this condition had a typical CHA type diffraction peak of SAPO-34, such as Figure 5 As shown, the SEM picture shows that the product is a spherical particle formed by the self-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com