Technical preparation method of glycyl glutamine

A technology of glycylglutamine and glutamine, applied in the direction of peptides, etc., can solve the problems of difficult removal of triethylamine, influence of drip acceleration rate, and high equipment requirements, so as to achieve easy control of the reaction, reduce equipment cost, and improve the reaction The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

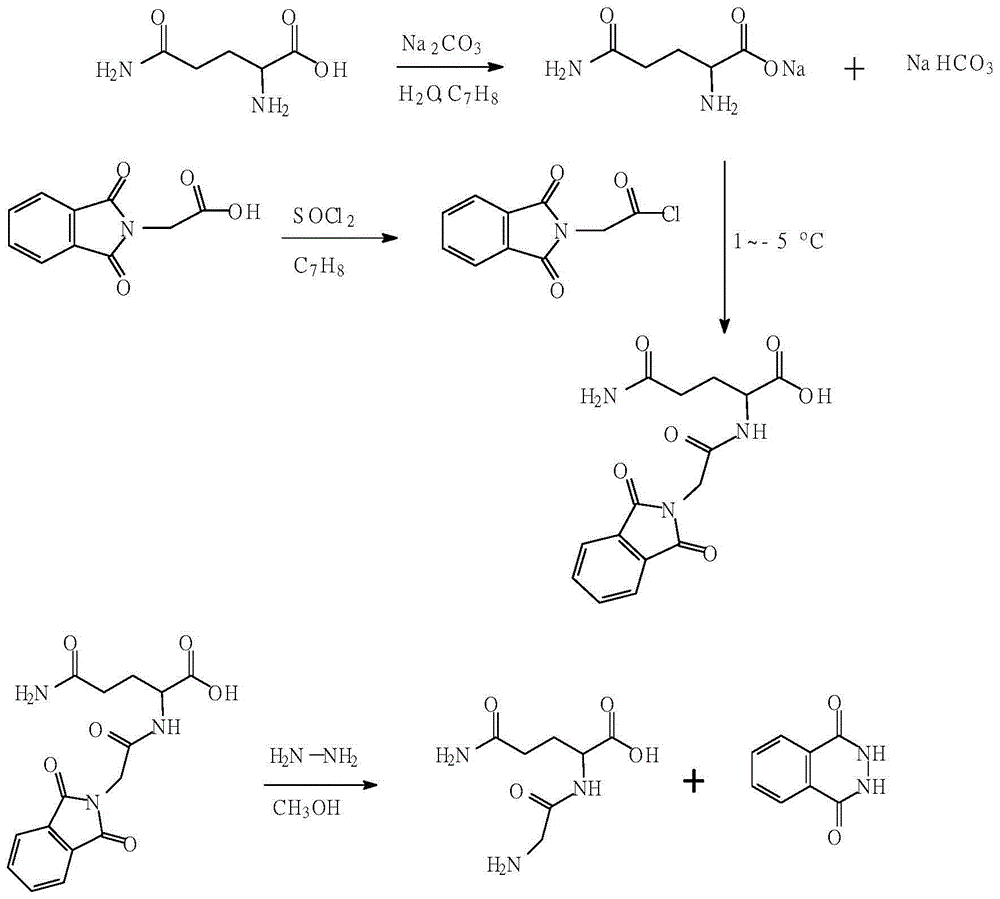

Method used

Image

Examples

Embodiment 1

[0021] (1) Add 8.52g of sodium carbonate, 11.74g of glutamine, 100mL of water and 40mL of toluene into a four-neck flask, place it in a low-temperature tank, stir and cool down to -2°C. Slowly add 16.4 g of freshly prepared phthaloylglycyl chloride (prepared from phthaloylglycine and thionyl chloride in 40 mL of toluene) to the above low-temperature stirred glutamine solution, dropwise The addition process lasted 4 hours and 20 minutes. When the dropwise amount of acid chloride reached 90%, it was found that the pH value of the reaction solution was 8, and then 2.0 g of sodium bicarbonate solid was added. After the acid chloride has been added dropwise, withdraw from the low-temperature tank, stir and naturally heat up. Then the lower aqueous phase was extracted, and concentrated hydrochloric acid was added dropwise until the pH was about 2.5, and a large amount of white solid precipitated. Finally, it was dried by suction filtration under low pressure to obtain 22.9 g of ph...

Embodiment 2

[0024] (1) Add 82.9g of potassium carbonate, 88.1g of glutamine, 750mL of water and 300mL of toluene into a four-necked flask, place it in a low-temperature tank, stir and cool down to -1°C. 123.0 g of freshly prepared phthaloylglycyl chloride (prepared from phthaloylglycine and thionyl chloride in 300 mL of toluene) was slowly added dropwise to the above low-temperature stirring glutamine solution, and the whole dropwise The addition process lasted 5 hours. When the dropwise amount of acid chloride reaches 92%, it is found that the pH value of the reaction solution is 8, then 9.0g potassium bicarbonate solid is added, and when the dropwise amount of acid chloride reaches about 97%, it is found that the pH value of the reaction solution is 8 , and then add 8.0 g of potassium bicarbonate solid. After the acid chloride has been added dropwise, withdraw from the low-temperature tank, stir and naturally heat up. Then the lower aqueous phase was extracted, and concentrated hydroc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com