Low-expansion ethylene-propylene rubber material

An ethylene-propylene rubber, low-expansion technology, applied in the field of low-expansion ethylene-propylene rubber materials, can solve problems such as poor stability, lack of polarity, and large volume expansion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

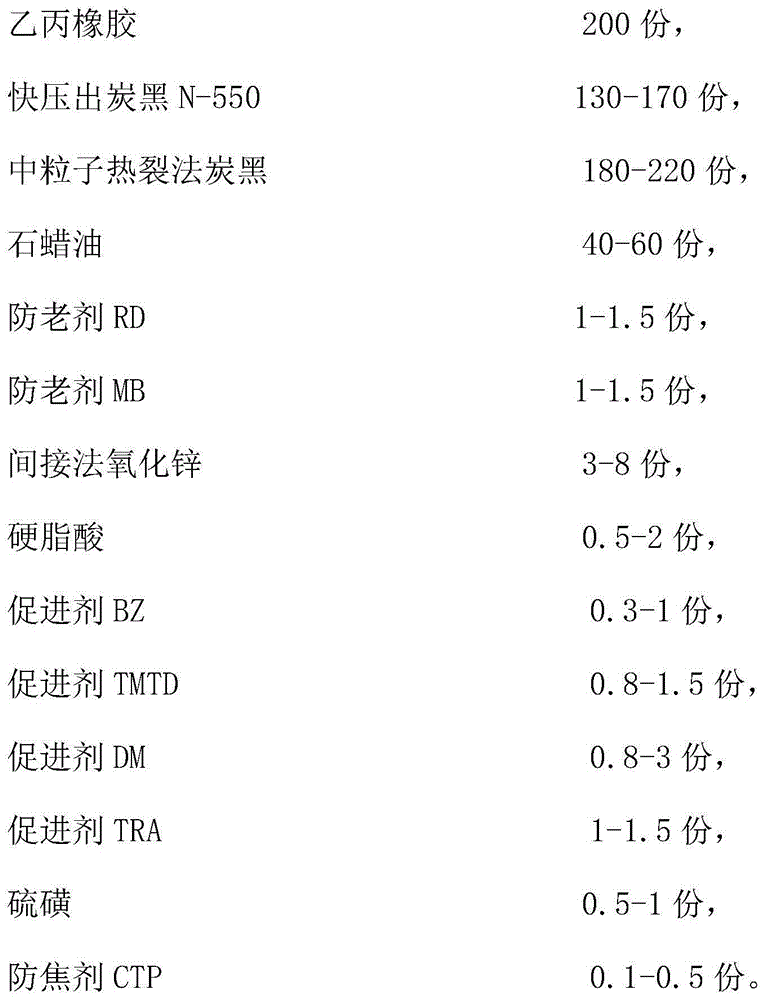

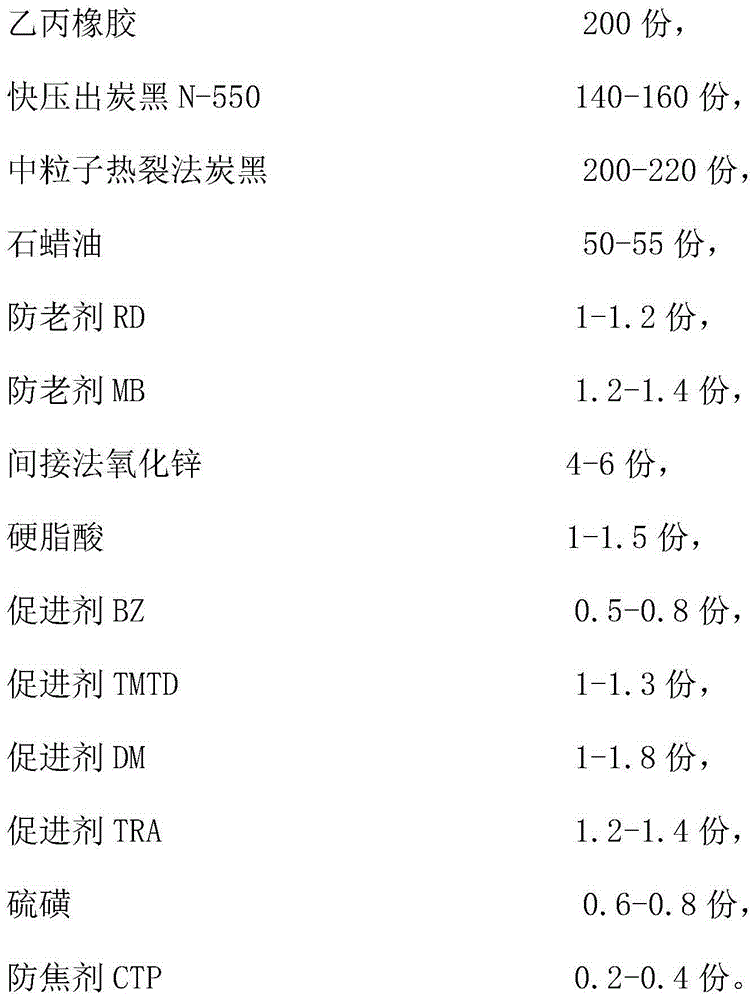

[0021] Below, the technical solution of the present invention will be described in detail through specific examples. In Examples 1-5, the raw materials of a low-expansion ethylene-propylene rubber material proposed by the present invention are composed as shown in the following table in parts by weight.

[0022] Component

[0023] Paraffin oil

[0024] Wherein, in embodiment 1, ethylene propylene rubber is the high Mooney ethylene propylene rubber that oil content is 95PHR; In embodiment 2, the iodine absorption value of quick extruding carbon black N-550 is 49mg / g; In embodiment 3, The ethylene-propylene rubber is a high Mooney EPDM rubber with an oil content of 100PHR. The iodine absorption value of the fast extruded carbon black N-550 is 43mg / g, and the DBP absorption value of the medium particle thermal black is 4.2×10 -4 m 3 / kg; In embodiment 4, the iodine absorption value of quick extruding carbon black N-550 is 37mg / g, and the DBP absorption value...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Iodine absorption value | aaaaa | aaaaa |

| Absorbance | aaaaa | aaaaa |

| Absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com