Fuel oil and preparation method thereof

A technology for fuel oil and kerosene, applied in the field of fuel oil, can solve the problems such as troublesome pretreatment of residual fuel heavy oil, limited processing and development capacity, high price of light diesel oil, etc., achieving low cost, promoting economic development, and high cetane number. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

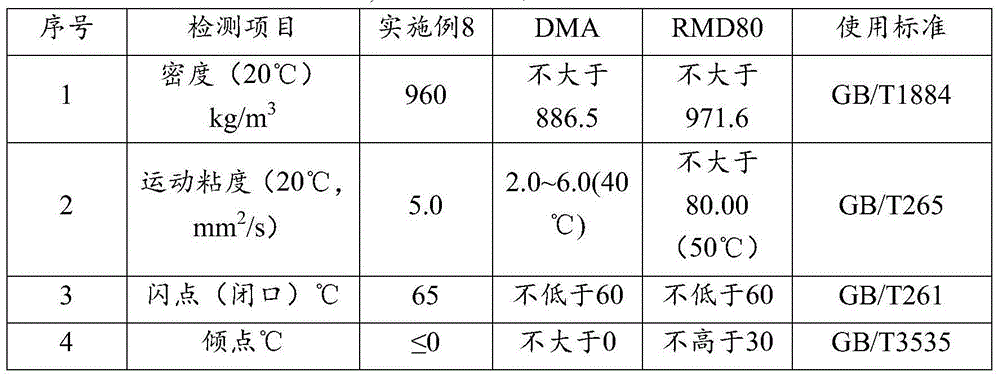

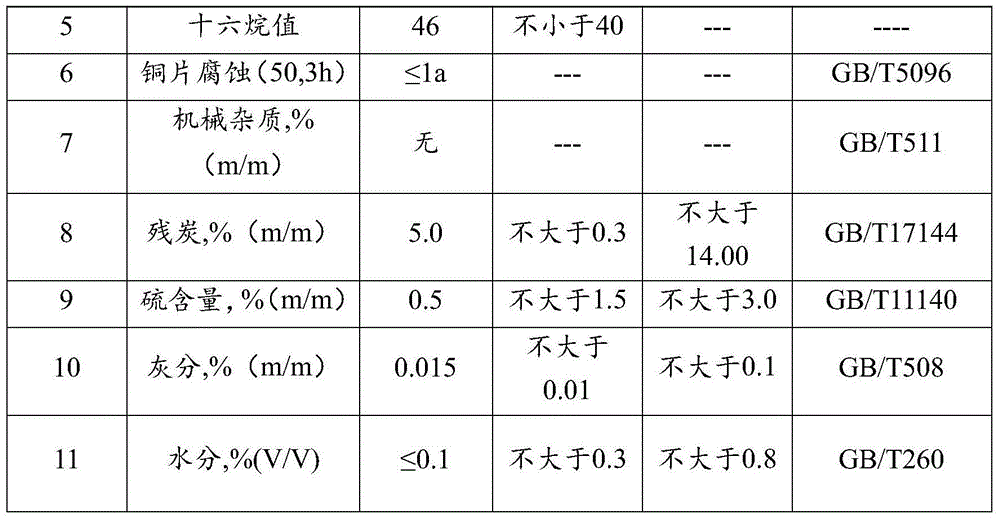

Examples

preparation example Construction

[0018] According to the method for preparing fuel oil of the present invention, the method includes raw materials by weight: 60 to 80 parts of base oil, 5 to 30 parts of kerosene, 5 to 20 parts of light diesel oil, 0.1 to 1 part of cetane number improver, 0.05 ~0.2 parts of low temperature flow improver and 0.01~0.1 parts of high-efficiency composite additives, of which,

[0019] The method includes the following operations: stirring, cooling, and centrifuging the base oil after crystallization; combining the kerosene, the light diesel oil, the cetane number improver, the low-temperature flow improver, and the high-efficiency composite additive with the base oil The oil is thoroughly mixed.

[0020] Among them, the base oil is preferably a washing oil; in addition, the base oil can also preferably be a mixture of 50 to 80 parts of anthracene oil and 20 to 50 parts of washing oil. Among them, anthracene oil is a part of coal tar components, and 280-360 degree fractions are collecte...

Embodiment 1

[0035] According to the preparation method of fuel oil of the present invention, the method includes raw materials by weight: 60 parts of base oil, 5 parts of kerosene, 5 parts of light diesel oil, 0.1 part of cetane number improver, 0.05 part of low temperature flow improver and 0.01 part High-efficiency composite additives, among which base oil is washing oil, kerosene is aviation kerosene, light diesel is 0# diesel, cetane number improver is isooctyl nitrate, low temperature flow improver is polyethylene-vinyl acetate, high-efficiency composite additive It is a mixture of 13 parts of ferrocene, 17 parts of ethylene glycol, 8 parts of calcium naphthenate, 7 parts of dodecanol and 42 parts of washing oil by weight; wherein, the method includes the following operations: After stirring, cooling, and crystallization, centrifugation; the kerosene, the light diesel oil, the cetane number improver, the low temperature flow improver, and the high-efficiency composite additive are full...

Embodiment 2

[0037] According to the preparation method of fuel oil of the present invention, the method includes raw materials by weight: 80 parts of base oil, 30 parts of kerosene, 20 parts of light diesel oil, 1 part of cetane number improver, 0.2 part of low temperature flow improver and 0.1 part High-efficiency composite additive, in which base oil is a mixture of 50 parts anthracene oil and 20 parts washing oil, kerosene is power kerosene, light diesel is 0# diesel, cetane number improver is amyl nitrate, and low temperature flow improver is long Alkyl naphthalene, the high-efficiency composite additive is made by mixing 18 parts of ferrocene, 23 parts of ethylene glycol, 13 parts of calcium naphthenate, 12 parts of dodecanol and 48 parts of washing oil by weight, wherein the method includes The following operations are as follows: the base oil is stirred, cooled, crystallized and then centrifuged; the kerosene, the light diesel oil, the cetane number improver, the low temperature flow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com