Method for modifying calcium sulphate whisker surface

A calcium sulfate whisker and surface modification technology, which is applied in chemical instruments and methods, crystal growth, inorganic compound addition, etc., can solve the problems of high cost, complicated operation, high solubility, etc., and achieve low cost, simple operation, physical and chemical The effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

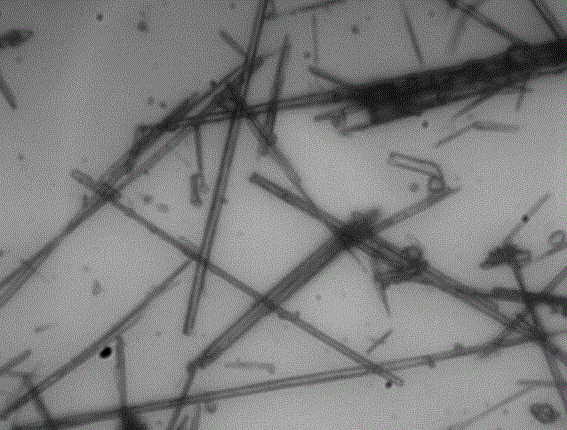

Image

Examples

Embodiment 1

[0023] At room temperature, add calcium sulfate whiskers to deionized water. The mass ratio of calcium sulfate whiskers to deionized water is 1:9. After stirring, put it into an ultrasonic disperser and shake for 2 minutes to obtain a suspension for use. Sodium aluminate was added to the shaken calcium sulfate whisker solution, the mass ratio of sodium aluminate to calcium sulfate whisker was 1:10, and the surface chemical wrapping reaction was carried out at a temperature of 60°C for 2 hours. After diluting 2g of dry fiber to a certain concentration, add modified calcium sulfate whiskers and stir evenly. Inject water into the paper former, pour the slurry when the water reaches the 4 liter mark, add fully dissolved 0.04% (to the pulp) cationic polyacrylamide (CPAM) retention aid before the automatic air stirring, after the paper is formed Squeeze, peel off the paper, and dry. According to the relevant national standard GB / T742-2008, the retention rate of calcium sulfate whis...

Embodiment 2

[0025] At room temperature, add calcium sulfate whiskers to deionized water. The mass ratio of calcium sulfate whiskers to deionized water is 1:9. After stirring, put it into an ultrasonic disperser and shake for 3 minutes to obtain a suspension for use. Sodium aluminate was added to the shaken calcium sulfate whisker solution, the mass ratio of sodium aluminate to calcium sulfate whisker was 1:30, and the surface chemical wrapping reaction was carried out at a temperature of 65°C for 2.5 hours. After diluting 2g of dry fiber to a certain concentration, add modified calcium sulfate whiskers and stir evenly. Inject water into the paper former, pour the slurry when the water reaches the 4 liter mark, add fully dissolved 0.04% (to the pulp) cationic polyacrylamide (CPAM) retention aid before the automatic air stirring, after the paper is formed Squeeze, peel off the paper, and dry. According to the relevant national standard GB / T742-2008, the retention rate of calcium sulfate wh...

Embodiment 3

[0027] At room temperature, add calcium sulfate whiskers to deionized water. The mass ratio of calcium sulfate whiskers to deionized water is 1:9. After stirring, put it into an ultrasonic disperser and shake for 4 minutes to obtain a suspension for use. Sodium aluminate was added to the shaken calcium sulfate whisker solution, the mass ratio of sodium aluminate to calcium sulfate whisker was 1:50, and the surface chemical wrapping reaction was carried out at a temperature of 70°C for 3 hours. After diluting 2g of dry fiber to a certain concentration, add modified calcium sulfate whiskers and stir evenly. Inject water into the paper former, pour the slurry when the water reaches the 4 liter mark, add fully dissolved 0.04% (to the pulp) cationic polyacrylamide (CPAM) retention aid before the automatic air stirring, after the paper is formed Squeeze, peel off the paper, and dry. According to the relevant national standard GB / T742-2008, the retention rate of calcium sulfate whis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com