Bridge deck continuous seam structure and forming method thereof

A bridge deck paving and bridge pier technology, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as top expansion of beams, accelerated rainwater infiltration, blocking beams, etc. The effect of developing and accelerating the attenuation of the amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

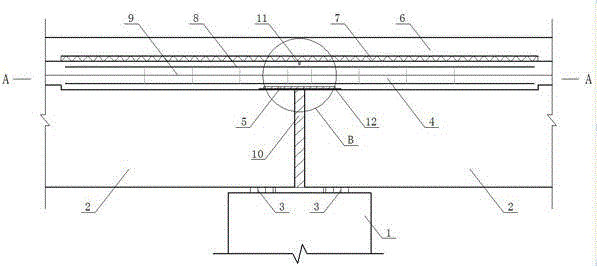

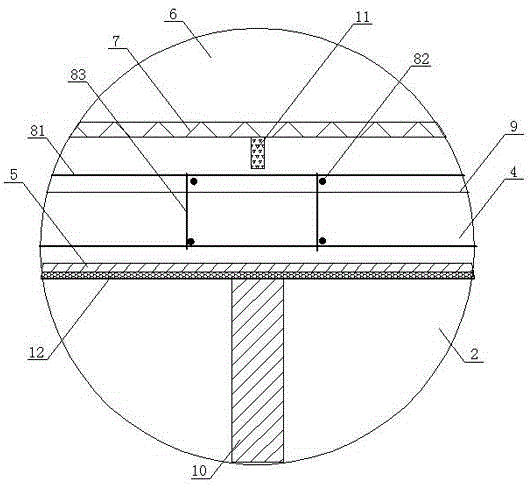

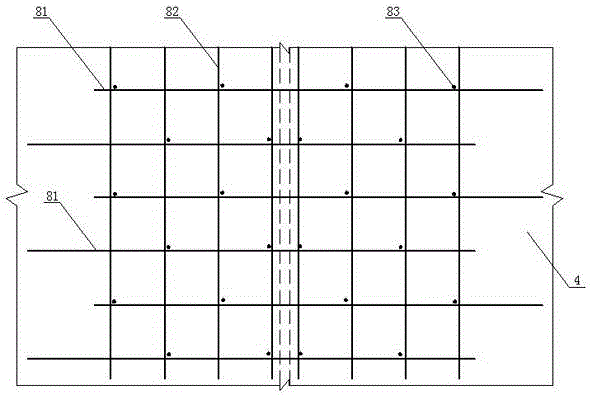

[0031] Such as figure 1 As shown, a bridge deck continuous seam structure provided by the embodiment of the present invention includes a bridge pier 1 and two supports 3 located on the top surface of the bridge pier 1, and two plate girders 2 located on the two supports 3, two Beam end joints are formed between the plate girders 2, and buffer blocks 10 are filled in the beam end joints, and a thermal asphalt adhesive layer 12 is arranged at the upper end of the plate girder 2, and the thermal asphalt adhesive layer 12 and the beam end joints are also The rubber cushion layer 5 is set. The setting of the buffer block 10 and the rubber cushion layer 5 can reduce the vibration energy transmitted from the vibration of the plate girder 2 to the continuous joi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com