Multi-graded concurrent tempering heat pump dehumidification and closed type circulating coarse cereal drying process method

A technology of slow heat pump and drying process, which is applied in the direction of saving seeds through drying and adapting to climate change. It can solve the problems of no recycling of sensible heat and latent heat and low energy rate, so as to reduce energy consumption and achieve good drying uniformity. , the effect of increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

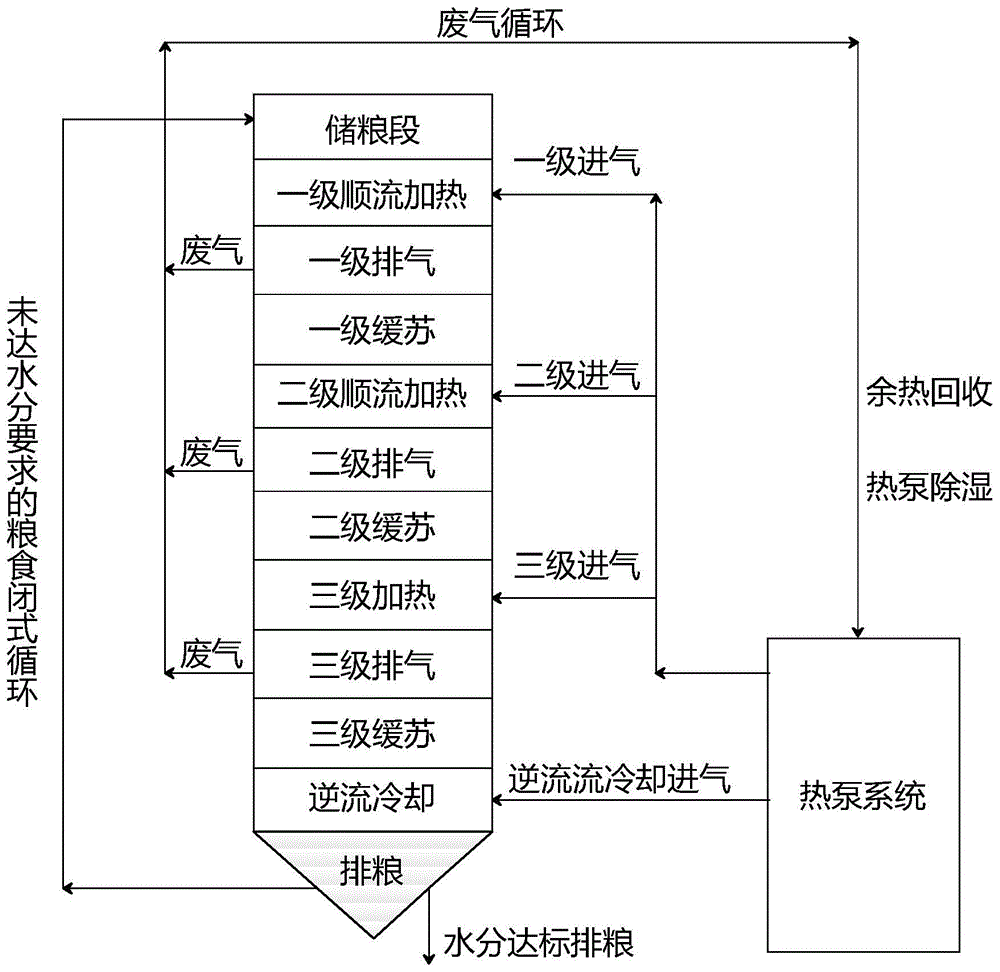

[0016] A multi-stage downstream slow-flow heat pump dehumidification and closed-cycle drying process for miscellaneous grains, characterized in that: the multi-stage downstream slow-flow heat pump dehumidification and drying device is used to dry and dehydrate the miscellaneous grains, and the multi-stage downstream slow-flow heat pump dehumidification and drying device There is a grain storage section that goes through the first level of downstream heating and drying, the first level of slowing, and the first level of exhaust; the second level of downstream heating and drying, the second level of slowing, and the second level of exhaust; Su, three-level exhaust; headwind cooling to reach grain discharge; its process method: according to the variety of miscellaneous grains, the initial moisture content and the change law of the moisture content of miscellaneous grains during the dehydration process, the expert intelligent control system is used to accurately control the paramete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com