Concentrated cow feed

A concentrated feed and dairy cow technology, applied in animal feed, animal feed, applications, etc., can solve problems such as low supply of trace elements, increased feeding costs, and imbalance of energy and nitrogen ratio, so as to improve the health of the body, reduce feed costs, The effect of increasing the milk fat percentage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A kind of high-yielding milk cow concentrate, its composition comprises by weight percentage:

[0025] Ingredients include: soybean meal 4%, corn gluten meal 35.8%, DDGS 24.6%, stone powder 10%, calcium hydrogen phosphate 5%, salt 5%, baking soda 9%, rumen-passed choline 1.5%, magnesium oxide 3%, yeast Composition 0.3%, 0.2% Lactation Premix 0.96%, Avimozinc 0.12%, Avimomanganese 0.06%, Avimocopper 0.06%, Biotin 0.06%, Yeast Selenium 0.04%, Mycotoxin Adsorbent 0.5%. The yeast composition is the product obtained by cultivating Saccharomyces cerevisiae, Candida rutatus, and Candida tropicalis at a ratio of 2:1:1, and fermenting the fermentation substrate, where the fermentation substrate is soybean meal , bran, molasses, ammonium sulfate, etc. as fermentation substrates.

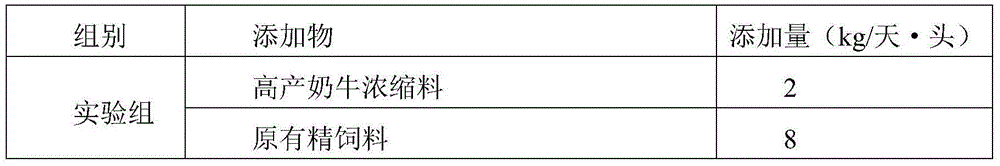

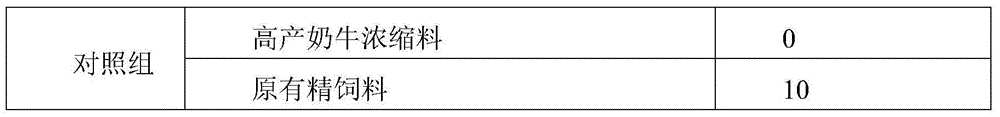

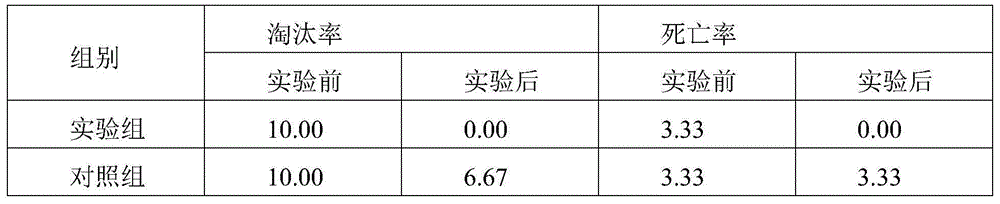

[0026] The experiment was carried out on a pasture in Hohhot for a period of 2 months. The original formula was used as the control group, and the high-yield milk cow concentrated feed formula was use...

Embodiment 2

[0064] The present invention also provides other two concentrate formulas, comprising by mass ratio:

[0065] Formula 1: soybean meal 4.4%, corn gluten meal 33.4%, DDGS 27.5%, stone powder 9.8%, calcium hydrogen phosphate 4.9%, salt 4.75%, baking soda 8.6%, rumen-passed choline 1.55%, magnesium oxide 2.84%, yeast Composition 0.45%, 0.2% Lactation Premix 0.9%, Amvilox Zinc 0.12%, Amvilox Manganese 0.07%, Amvilox Copper 0.06%, Biotin 0.06%, Yeast Selenium 0.05%, Mycotoxin Adsorbent 0.55%. The yeast composition is the product obtained by cultivating Saccharomyces cerevisiae, Candida ruguens, and Candida tropicalis at a ratio of 3:2:1, and fermenting the fermentation substrate, where the fermentation substrate is soybean meal , bran, molasses, ammonium sulfate, etc. as fermentation substrates.

[0066] Formula 2: soybean meal 4.5%, corn gluten meal 38%, DDGS 20.4%, stone powder 11%, calcium hydrogen phosphate 5.5%, salt 4.5%, baking soda 8.5%, rumen-passed choline 1.6%, magnesiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com