A kind of temperature-resistant and salt-resistant water-in-oil nanoemulsion and preparation method thereof

A nanoemulsion, heat-resistant and salt-resistant technology, applied in mixing methods, chemical instruments and methods, dissolution, etc., can solve problems such as poor stability, and achieve the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Take by weighing 1.6g T154, 33.6g white oil, 4.8g 18wt% calcium chloride brine (T154 weight percent 4%, white oil weight percent 84, calcium chloride brine weight percent 12%), mix in beaker, control system temperature Keep it at 80°C, stir on a magnetic stirrer at 400rpm for 3min (minutes) to make the system evenly stirred, at this time, use ultrasonic emulsification method, ultrasonic at 400W for 200s (seconds), and the nanoemulsion can be obtained. The average particle diameter of the emulsion measured by BI-200SM dynamic light scattering instrument is 454.7nm. The nanoemulsion was aged in a high temperature roller furnace at 180° C. for 12 hours (hours), and the average particle diameter of the emulsion was measured by a BI-200SM dynamic light scattering instrument to be 321.6 nm.

Embodiment 2

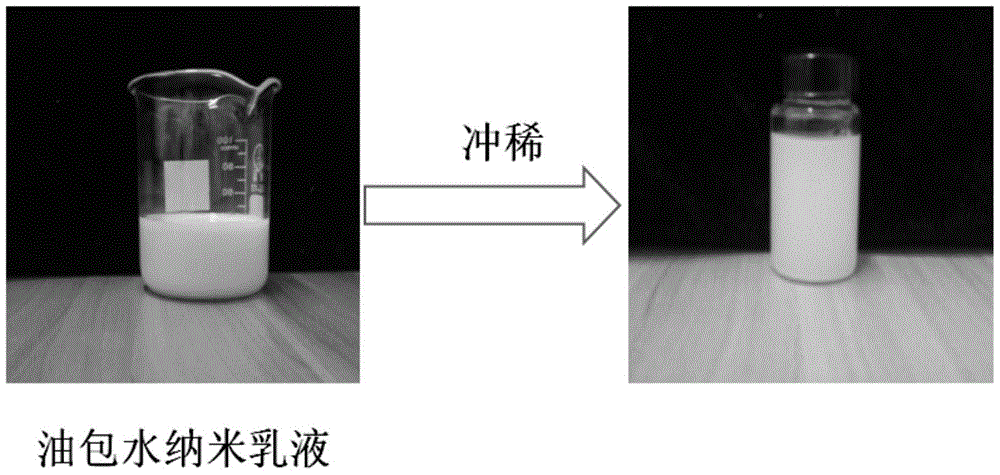

[0019] Weigh 2g OLOA1200, 28g n-dodecane, 10g 22wt% sodium chloride and the brine of calcium sulfate mass ratio 1:1 mixture (OLOA1200 weight percent 2%, n-dodecane weight percent 73%, the weight percent 25% of brine ), mix in a beaker, keep the temperature of the system at 60°C, and stir for 3 minutes at a speed of 650rpm on a magnetic stirrer to make the system evenly stirred. At this time, use ultrasonic emulsification method, ultrasonic at 300W for 200s, and nanoemulsion can be obtained . The average particle diameter of the emulsion measured by a BI-200SM dynamic light scattering instrument is 364nm. The nanoemulsion was aged in a high temperature roller furnace at 180° C. for 12 hours, and the average particle size of the emulsion was measured by a BI-200SM dynamic light scattering instrument to be 243.5 nm. The emulsion is diluted with a certain amount of white oil to obtain an emulsion such as figure 1 shown.

Embodiment 3

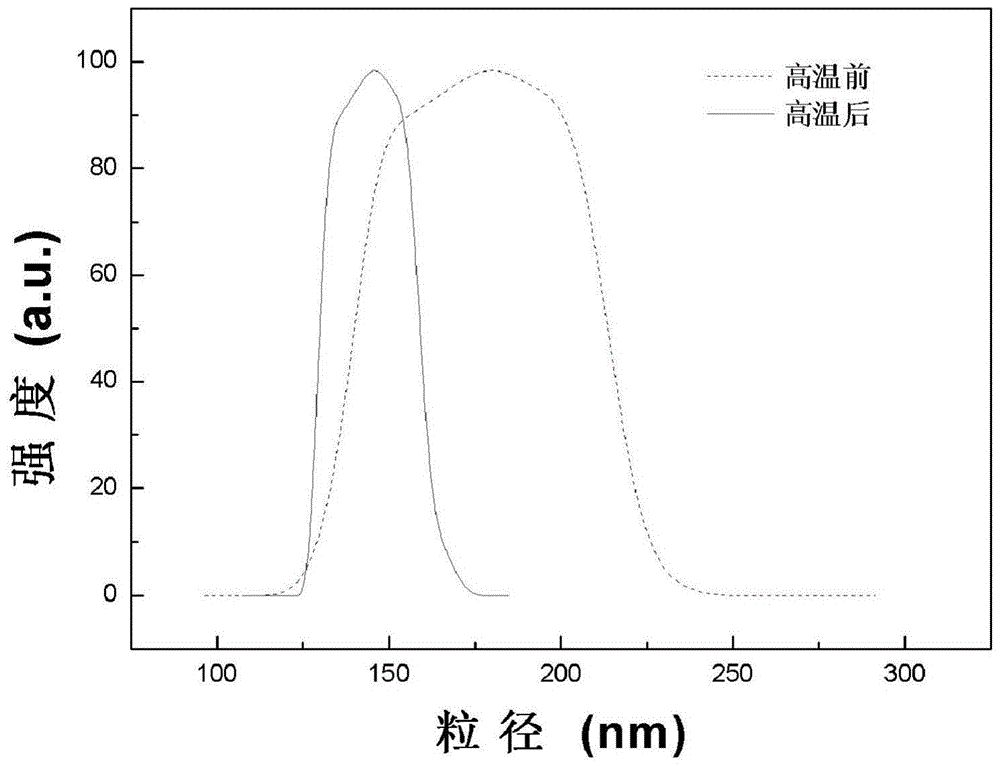

[0021] Take by weighing 4g LZ890, 26g liquid paraffin and 10g 20wt% iron bromide brine (LZ890 weight percentage 10%, liquid paraffin weight percentage 65%, ferric bromide brine weight percentage 25%), mix in beaker, control system temperature and keep at At 70°C, stir on a magnetic stirrer at a speed of 400rpm for 4min to make the system evenly stirred. At this time, use ultrasonic emulsification method, ultrasonic at 200W for 200s, and the nanoemulsion can be obtained. The average particle diameter of the emulsion measured by BI-200SM dynamic light scattering instrument is 201.6nm. The nanoemulsion was aged in a high-temperature roller furnace at 180° C. for 12 hours, and the average particle size of the emulsion was measured by a BI-200SM dynamic light scattering instrument to be 179.6 nm. Its particle size distribution is as figure 2 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com