Method for determining diameter of mineral steel ball harder than gangue mineral and used for grinding valuable mineral

A technology of useful minerals and determination methods, applied in the application of stable tension/pressure testing material strength, grain processing, testing material hardness, etc. There are deviations and other problems to achieve the effect of enhancing the content of the intermediate easy-to-select particle size, reasonable particle size composition, and reducing the particle size content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

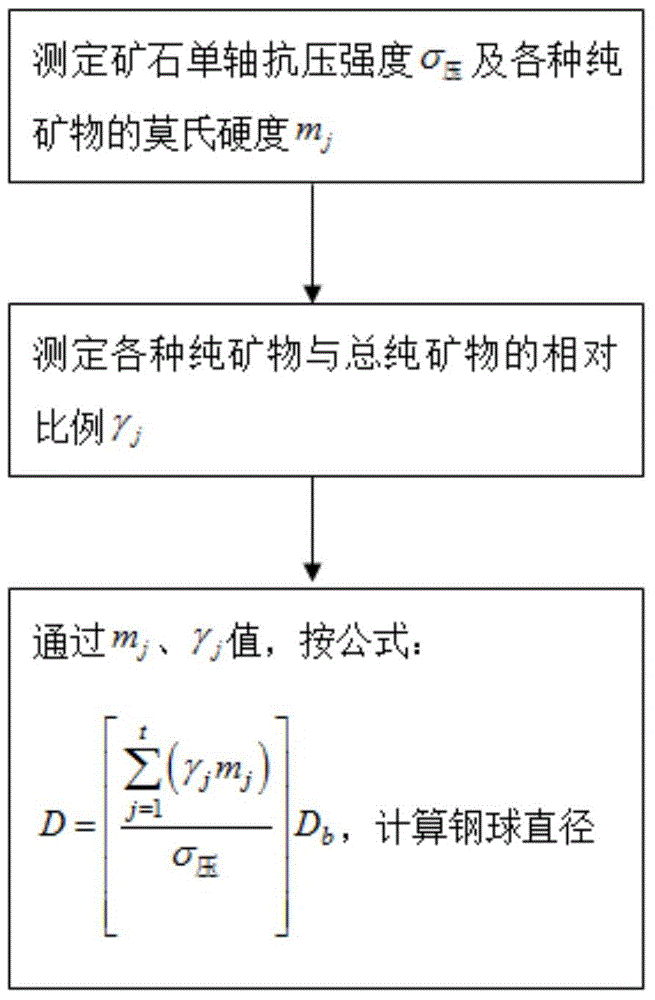

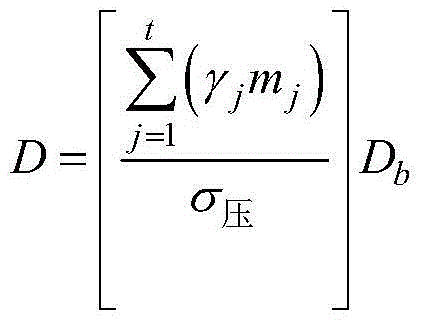

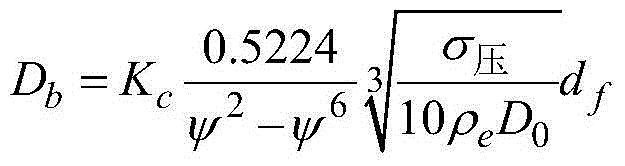

[0031] Embodiment 1: as figure 1 As shown, a method for determining the diameter of a steel ball for grinding useful minerals harder than gangue minerals, the specific steps of the method are as follows:

[0032] Step1. Determination of ore mechanical properties

[0033] Select n pieces of ore whose length, width and height are greater than 20cm before coarse crushing, cut into cylindrical standard specimens of the same standard, measure the uniaxial compressive strength of each standard specimen on the material testing machine and calculate the arithmetic mean of the measurement results Value as ore uniaxial compressive strength σ 压 ; At the same time, use the scratch method to measure the Mohs hardness m of various pure minerals in the raw ore j ;

[0034] Step2. Determination of relative content of minerals

[0035] Use point measurement or line measurement on a microscope to determine the relative content of various minerals in raw oreγ i ; determine the relative prop...

Embodiment 2

[0042] Embodiment 2: as figure 1 As shown, a method for determining the diameter of a steel ball for grinding useful minerals harder than gangue minerals, the specific steps of the method are as follows:

[0043] Step1. Determination of ore mechanical properties

[0044] Select n pieces of ore whose length, width and height are greater than 20cm before coarse crushing, cut into cylindrical standard specimens of the same standard, measure the uniaxial compressive strength of each standard specimen on the material testing machine and calculate the arithmetic mean of the measurement results Value as ore uniaxial compressive strength σ 压 ; At the same time, use the scratch method to measure the Mohs hardness m of various pure minerals in the raw ore j ;

[0045] Step2. Determination of relative content of minerals

[0046] Use point measurement or line measurement on a microscope to determine the relative content of various minerals in raw oreγ i ; determine the relative prop...

Embodiment 3

[0051] Embodiment 3: as figure 1 As shown, a method for determining the diameter of a steel ball for grinding useful minerals harder than gangue minerals, the specific steps of the method are as follows:

[0052] Raw material: Copper-bearing pyrrhotite from Dongguashan Copper Mine in Anhui Province

[0053] (1) Determination of ore mechanical properties

[0054] Before coarse crushing, select 10 pieces of ore whose length, width and height are greater than 20cm, cut them into standard 5×5×10cm or 4×4×8cm cylindrical standard test pieces, and measure the uniaxiality of each ore test piece on a material testing machine Compressive strength, calculate the arithmetic mean σ of the measurement results 压 5505kg / cm 2 . In addition, the Mohs hardness of chalcopyrite is 6, that of pyrite is 6.5, that of pyrrhotite is 4, that of magnetite is 6, and that of serpentine is measured by scratch method. The Mohs hardness of chlorite is 3.5, the Mohs hardness of chlorite is 2.5, and the M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com