Preparation method of rare-earth fluorescent molecularly imprinted membrane and application of rare-earth fluorescent molecularly imprinted membrane

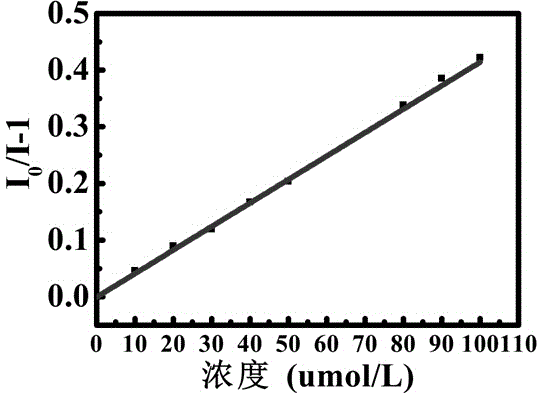

A molecularly imprinted membrane and rare earth fluorescence technology, applied in the field of preparation of rare earth fluorescent imprinted membrane, can solve the problems of poor selectivity of adsorbents, high cost, secondary pollution, etc., and achieve the effects of high sensitivity, reduction of detection time, and improvement of sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) EuCl 3 0.5 mmol, 0.75 mmol of phen, and 0.5 mmol of TTA were dissolved in 100 mL of ethanol, stirred evenly by magnetic force, and concentrated ammonia water was added dropwise. Adjust pH=7, the solution becomes turbid. Continue stirring for 2 h, centrifuge, and wash three times with ethanol. The Eu(III) complex is obtained.

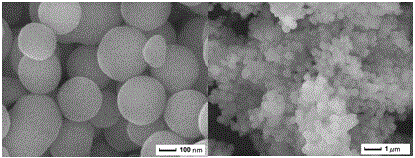

[0039](2) Dissolve 100 mg of Eu(III) complex in step (1) in 5 mL of DMF. Form solution A with a mixed solution of 25 ml ethanol and 1 mL TEOS. Then 1 mL of ammonia water was added to the mixed solution of 14 ml of ethanol and 5 ml of distilled water to form solution B, then solution A was quickly poured into solution B, and magnetically stirred for 2 h. centrifuged and washed three times to obtain Eu(III)SiO 2 .

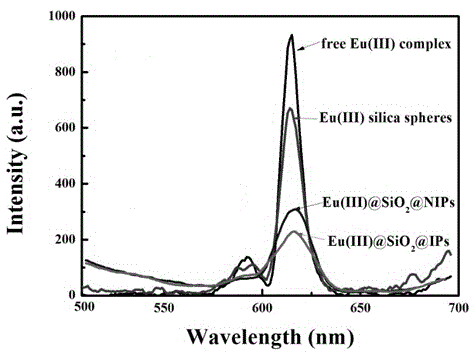

[0040] (3) Eu(III)SiO obtained in (2) 2 0.1 g was dispersed in 30 mL of acetonitrile, and then 0.35 mmol of methacrylic acid (MAA), 1.50 mL of ethylene glycol dimethacrylate (EGDMA), and 0.10 mmol of cyfluthrin were added. ...

Embodiment 2

[0045] (1) EuCl 3 0.5 mmol, 0.5 mmol of phen, and 0.5 mmol of TTA were dissolved in 100 mL of ethanol, stirred evenly by magnetic force, and concentrated ammonia water was added dropwise. Adjust pH=7, the solution becomes turbid. Continue stirring for 2 h, centrifuge, and wash three times with ethanol. The Eu(III) complex is obtained.

[0046] (2) Dissolve 20 mg of the Eu(III) complex in step (1) in 1 mL of DMF. Form solution A with a mixed solution of 5 ml ethanol and 0.19 mL TEOS. Then 0.2 mL of ammonia water was added to the mixed solution of 3.5 mL of ethanol and 1.3 mL of distilled water to form solution B, then solution A was quickly poured into solution B, and magnetically stirred for 2 h. centrifuged and washed three times to obtain Eu(III)SiO 2 .

[0047] (3) Disperse 0.12 g of the fluorescent material obtained in (2) in 30 mL of acetonitrile, and then add 0.50 mmol of methacrylic acid (MAA), 1.55 mL of ethylene glycol dimethacrylate (EGDMA), and 0.12 mmol of c...

Embodiment 3

[0053] (1) EuCl 3 0.5 mmol, 0.5 mmol of phen, and 0.5 mmol of TTA were dissolved in 100 mL of ethanol, stirred evenly by magnetic force, and concentrated ammonia water was added dropwise. Adjust pH=7, the solution becomes turbid. Continue stirring for 2 h, centrifuge, and wash three times with ethanol. The Eu(III) complex is obtained.

[0054] (2) Dissolve 50 mg of the Eu(III) complex in step (1) in 2 mL of DMF. The mixed solution with 10ml ethanol and 0.5 mL TEOS forms solution A. Then 0.4 mL of ammonia water was added to the mixed solution of 7 ml of ethanol and 2.5 ml of distilled water to form solution B, then solution A was quickly poured into solution B, and magnetically stirred for 2 h. centrifuged and washed three times to obtain Eu(III)SiO 2 .

[0055] (3) Disperse 0.12 g of the fluorescent material obtained in (2) in 30 mL of acetonitrile, and then add 0.60 mmol of methacrylic acid (MAA), 1.70 mL of ethylene glycol dimethacrylate (EGDMA), and 0.15 mmol of cyfl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com