Preparation method of high-performance carbon nano tube/epoxy resin

A technology of carbon nanotubes and epoxy resins, which is applied in the field of preparation of performance carbon nanotubes/epoxy resins, can solve the problems of poor amination modification, high polarity of amino groups, and weak interfacial binding force and other issues, to achieve the effects of improved performance indicators, easy storage, improved modulus and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

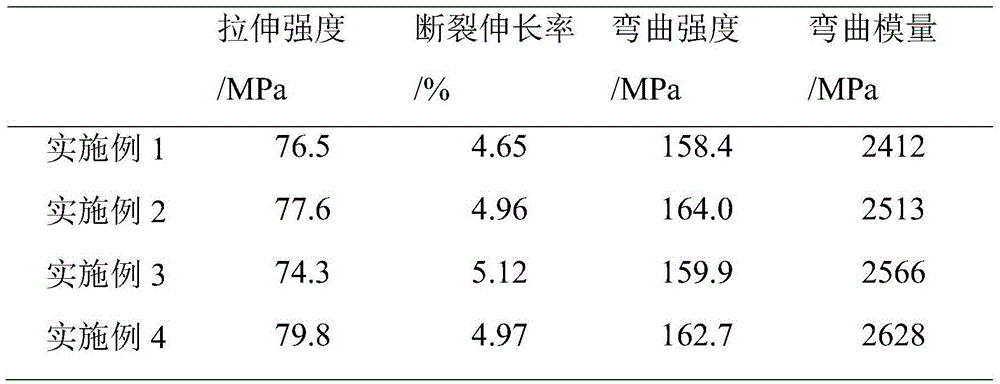

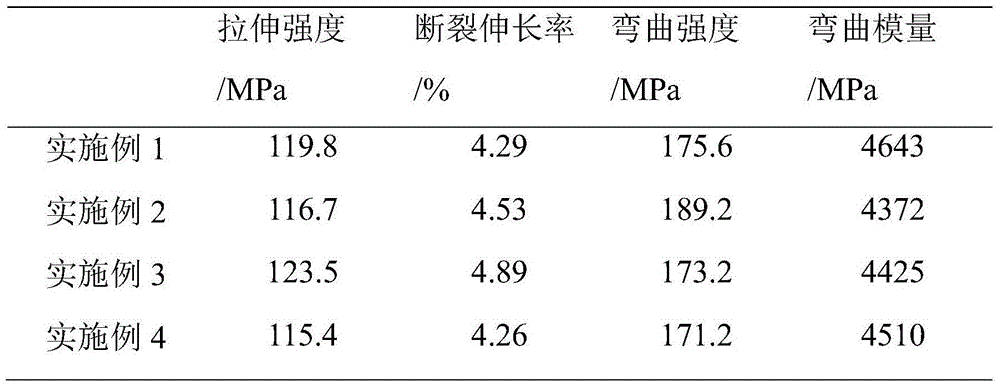

Embodiment 1

[0037] There are four kinds of components in the present embodiment, are respectively:

[0038] Component 1: aminated multi-walled carbon nanotubes, the aminated carbon nanotubes are aminated carbon nanotubes grafted with diethyltoluenediamine on the surface purchased by Chengdu Organic Chemistry Co., Ltd., Chinese Academy of Sciences.

[0039] Component 2: benzyl glycidyl ether;

[0040] Component 3: diaminodiphenylethane;

[0041] Component 4: Diethyltoluenediamine.

[0042] The specific implementation steps of this embodiment are as follows:

[0043] 1. Grinding the aminated carbon nanotubes.

[0044] 2. Put the ground carbon nanotubes into an electric vibrating sieve machine, and sieve the aminated carbon nanotubes with a mesh number of 100.

[0045] 3. Add 0.5 g of the 100-mesh aminated carbon nanotubes sieved in step 2 to 0.5 g of benzyl glycidyl ether, and stir mechanically at room temperature for 3 hours to obtain a black viscous liquid, which is named as mixture I...

Embodiment 2

[0052] The raw material of present embodiment is with embodiment 1, and concrete implementation steps are as follows:

[0053] 1. Grinding the aminated carbon nanotubes.

[0054] 2. Put the ground carbon nanotubes into an electric vibrating sieve machine, and sieve the aminated carbon nanotubes with a mesh number of 50.

[0055] 3. Add 0.5 g of the 50-mesh aminated carbon nanotubes sieved in step 2 to 0.75 g of benzyl glycidyl ether, and stir mechanically at room temperature for 2 hours to obtain a black viscous liquid, which is named as mixture I.

[0056] 4. Add the mixture Ⅰ into the planetary ball mill, and ball mill for 4 hours under the protection of nitrogen. The speed of the ball mill is 200-500r / min. After 10 minutes of continuous ball milling, a 5-minute interval is required to obtain a uniform black viscous liquid, which is named mixture Ⅱ.

[0057] 5. The mixture II was mechanically stirred in an oil bath at 150° C. for 3 h to obtain the mixture III.

[0058] 6. ...

Embodiment 3

[0062] The raw material of present embodiment is with embodiment 1, and concrete implementation steps are as follows:

[0063] 1. Grinding the aminated carbon nanotubes.

[0064] 2. Put the ground carbon nanotubes into an electric vibrating sieve machine, and sieve the aminated carbon nanotubes with a mesh number of 80.

[0065] 3. Add 2 g of the 80-mesh aminated carbon nanotubes sieved in step 2 to 2 g of benzyl glycidyl ether, and stir mechanically at room temperature for 2 h to obtain a black viscous liquid, which is named as mixture I.

[0066] 4. Add the mixture Ⅰ into the planetary ball mill, ball mill for 3 hours under the protection of nitrogen, the speed of the ball mill is 200-500r / min, after 10 minutes of continuous ball milling, a 5-minute interval is required to obtain a uniform black viscous liquid, which is named as the mixture Ⅱ.

[0067] 5. The mixture II was mechanically stirred in an oil bath at 150° C. for 3 h to obtain the mixture III.

[0068] 6. The mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com