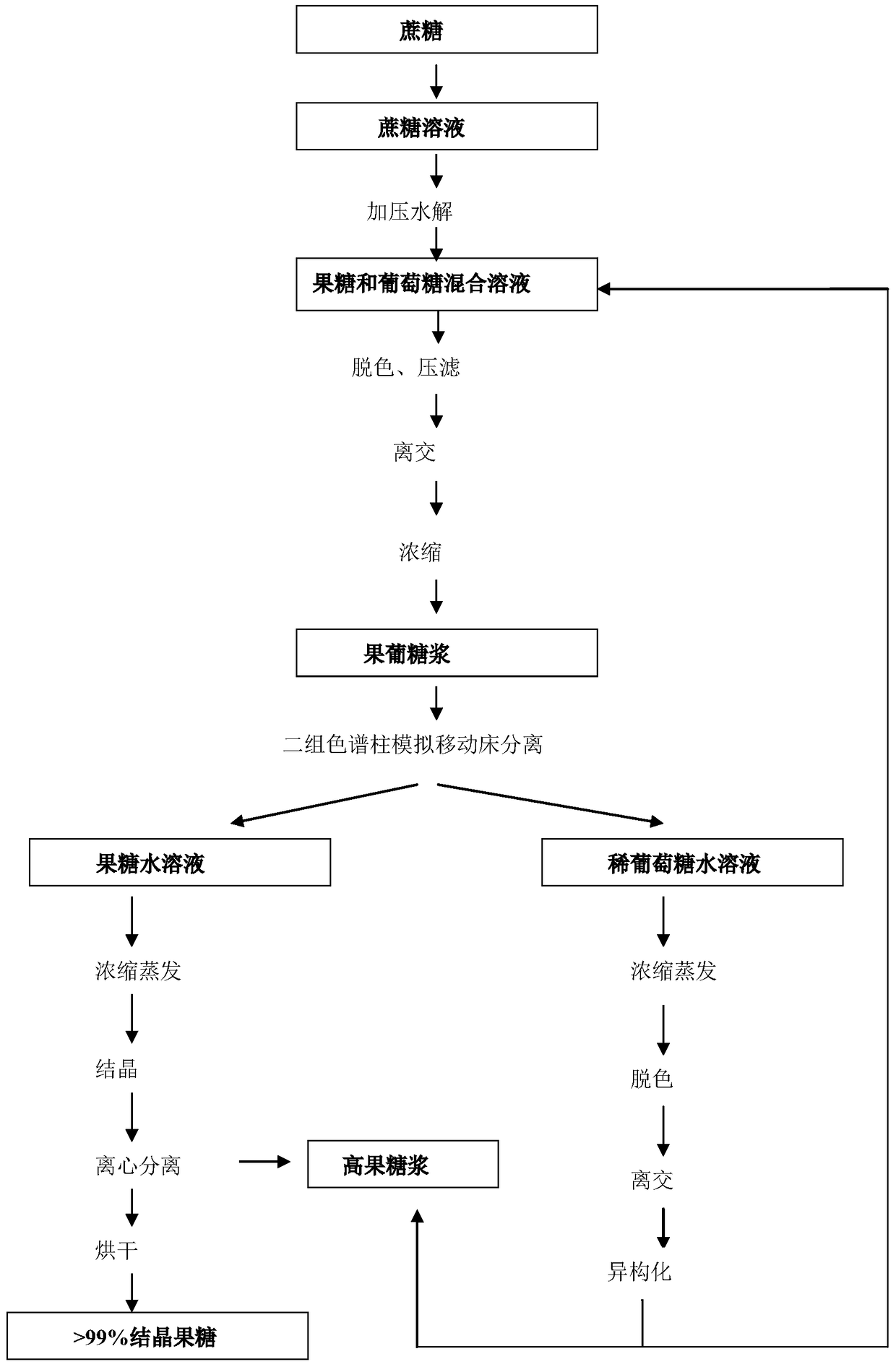

A method for producing crystalline fructose from sucrose

A technology for crystallizing fructose and fructose, applied in the field of sucrose production of crystallized fructose, can solve the problems of high cost, low production efficiency and high energy consumption, and achieve the effects of low cost, equipment improvement and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1) Pressurized hydrolysis of sucrose

[0034]Dissolve sucrose in water to obtain a sugar solution with a concentration of 55%, add it to the reaction pot and stir; open the steam valve, wait until the steam pressure in the reaction pot is 0.15Mpa, and when the temperature rises to 111°C, close the steam valve, and then add 5 % dilute hydrochloric acid, adjust the pH value of the solution to 2.5, and then keep it warm for 30 minutes. The test shows that the fructose content is >42%. It is a mixed solution of 47% fructose and glucose.

[0035] 2) Decolorization and separation

[0036] Send the mixed solution obtained in step 1) into the decolorization tank through the decolorization pump, and pump compressed air to make the sugar solution tumbling, then add an appropriate amount of activated carbon, tumbling evenly, after about 20 minutes, stop pumping compressed air, and start while it is hot Decolorization and filtration; Each decolorization tank is alternately fed an...

Embodiment 2

[0047] 1) Hydrolysis of sucrose

[0048] Dissolve sucrose in water to obtain a sugar solution with a concentration of 45%, add it to the reaction pot and stir; open the steam valve, wait until the steam pressure in the reaction pot is 0.20Mpa, and when the temperature rises to 120°C, close the steam valve, and then add 5 % dilute hydrochloric acid, adjust the pH value of the solution to 2.8, and then keep it warm for 60 minutes. The test shows that the fructose content is >42%. It is a mixed solution of 46% fructose and glucose.

[0049] 2) Decolorization and separation

[0050] With embodiment 1.

[0051] 3) Chromatographic separation: send the above fructose syrup through the flow regulating valve and high-purity water into the two sets of columns to simulate the moving bed, and automatically adjust the inlet and outlet through the automatic control system according to the temperature, pressure, flow, flow rate and other parameters in the bed The pressure of the material ...

Embodiment 3

[0056] 1) Hydrolysis of sucrose

[0057] Dissolve sucrose in water to obtain a sugar solution with a concentration of 40%, add it to the reaction pot and stir; open the steam valve, wait until the steam pressure in the reaction pot is 0.3Mpa, and when the temperature rises to 130°C, close the steam valve, and then add 5 % dilute hydrochloric acid, adjust the pH value of the solution to 3, and then keep it warm for 45 minutes. The test shows that the fructose content is >42%. It is a mixed solution of 45% fructose and glucose.

[0058] 2) Decolorization and separation

[0059] With embodiment 1.

[0060] 3) Chromatographic separation

[0061] The fructose syrup mentioned above is sent into the two sets of column simulated moving bed through the flow regulating valve and high-purity water. According to the temperature, pressure, flow rate, flow rate and other parameters in the bed, the pressure and the pressure of the inlet and outlet material pumps are automatically adjusted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com