Tussah silk fabric functional finishing agent, finishing method and tussah silk fabric obtained by finishing

A functional finishing agent, the technology of tussah silk, applied in textiles and papermaking, textile material processing, liquid/gas/vapor textile processing and other directions, can solve the problems of reduced mechanical strength, unsatisfactory UV resistance, etc., and achieve mechanical strength. The effect of reduced reduction, easy industrial-scale production and application, and reduced input cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

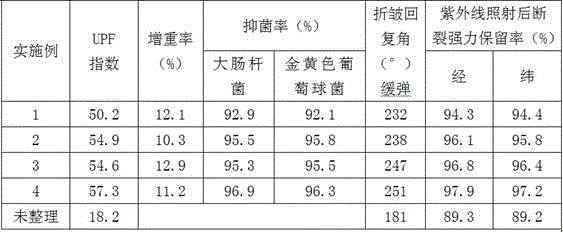

Examples

Embodiment 1

[0017] 1. The tussah silk fabric functional finishing agent is obtained through the following steps:

[0018] A, the acquisition of chestnut leaf extract:

[0019] Wash and crush dead chestnut leaves, immerse in water at a bath ratio of 1:15, soak at room temperature until soaked, then raise the temperature to 80°C, keep stirring for 90 minutes, then filter out impurities to obtain chestnut leaf extract stock solution;

[0020] b. The raw material composition of the functional finishing agent includes: chestnut leaf extract stock solution, 1,2-pentanediol and acid regulator, wherein 1,2-pentanediol is 5g / L, and the acid regulator makes the pH value of the functional finishing agent Adjusted to 4.5, the rest is chestnut leaf extract stock solution; the acid regulator is any one of glacial acetic acid, citric acid, tartaric acid, acetic acid-sodium acetate.

[0021] 2. Finishing method of tussah silk fabric:

[0022] The degummed tussah silk fabric is immersed in the above fun...

Embodiment 2

[0024] 1. The tussah silk fabric functional finishing agent is obtained through the following steps:

[0025] A, the acquisition of chestnut leaf extract:

[0026] Wash and crush dead chestnut leaves, immerse in water at a bath ratio of 1:15, soak at room temperature until saturated and macerated, then raise the temperature to 100°C, keep stirring for 60 minutes, then filter out impurities to obtain chestnut leaf extract stock solution ;

[0027]b. The raw material composition of the functional finishing agent includes: chestnut leaf extract stock solution, 1,2-pentanediol and acid regulator, wherein 1,2-pentanediol is 10g / L, and the acid regulator makes the pH value of the functional finishing agent Adjusted to 5.5, the rest is chestnut leaf extract stock solution; the acid regulator is any one of glacial acetic acid, citric acid, tartaric acid, acetic acid-sodium acetate.

[0028] 2. Finishing method of tussah silk fabric:

[0029] a. Pretreatment of tussah silk fabrics, ...

Embodiment 3

[0033] 1. The tussah silk fabric functional finishing agent is obtained through the following steps:

[0034] A, the acquisition of chestnut leaf extract:

[0035] Wash and crush dead chestnut leaves, immerse in water at a bath ratio of 1:20, soak at room temperature until saturated and macerated, then heat up to 100°C, keep warm and stir for 60 minutes, then filter out impurities to obtain chestnut leaf extract stock solution;

[0036] b. The raw material composition of the functional finishing agent includes: chestnut leaf extract stock solution, 1,2-pentanediol and acid regulator, wherein 1,2-pentanediol is 7g / l, the acidity is adjusted to 5.0, and the rest is chestnut leaf extract stock solution, the acid regulator is any one of glacial acetic acid, citric acid, tartaric acid, acetic acid-sodium acetate.

[0037] 2. Finishing method of tussah silk fabric:

[0038] a. Immerse the degummed tussah silk fabric in the functional finishing solution with a bath ratio of 1:30, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com