Electrostatic atomizing and cooling capacity evaluation device with adjustable nozzle space angle

A technology of electrostatic atomization and spatial angle, applied in the field of heat exchange and cooling, it can solve the problems such as difficulty of cutting fluid entering the cutting area, increase in cost, environmental pollution, etc., to make up for critical heat flux density and heat transfer coefficient, convenient application, and device integration. high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

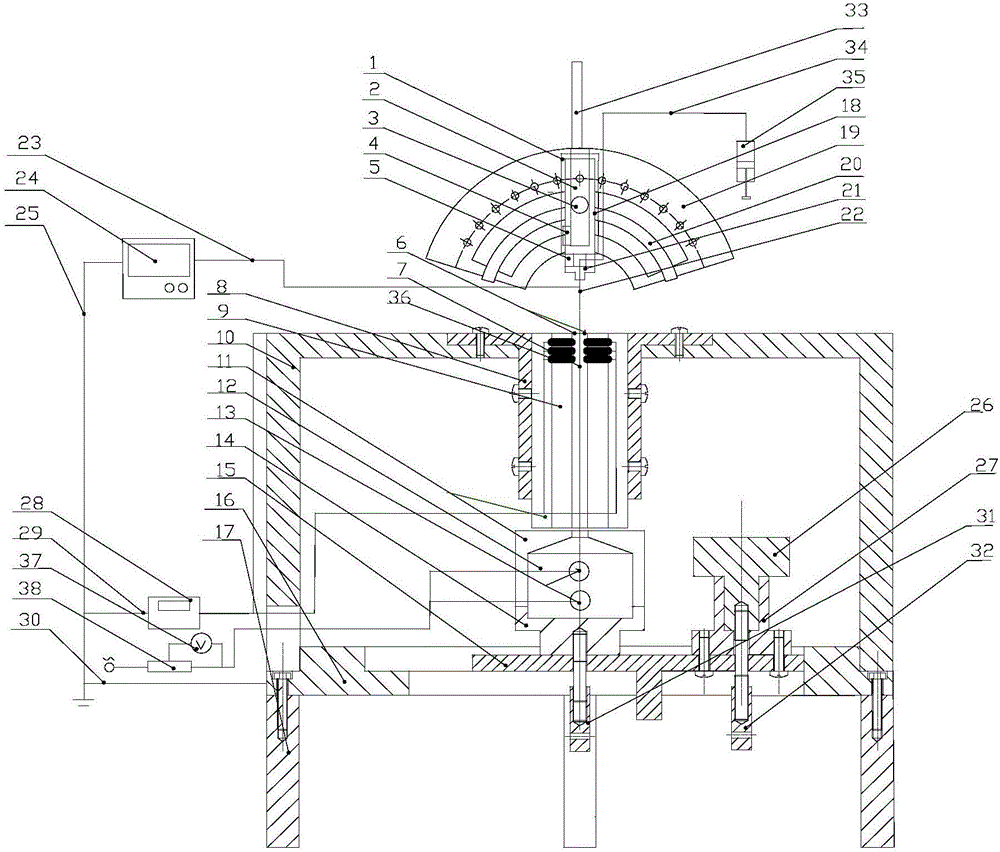

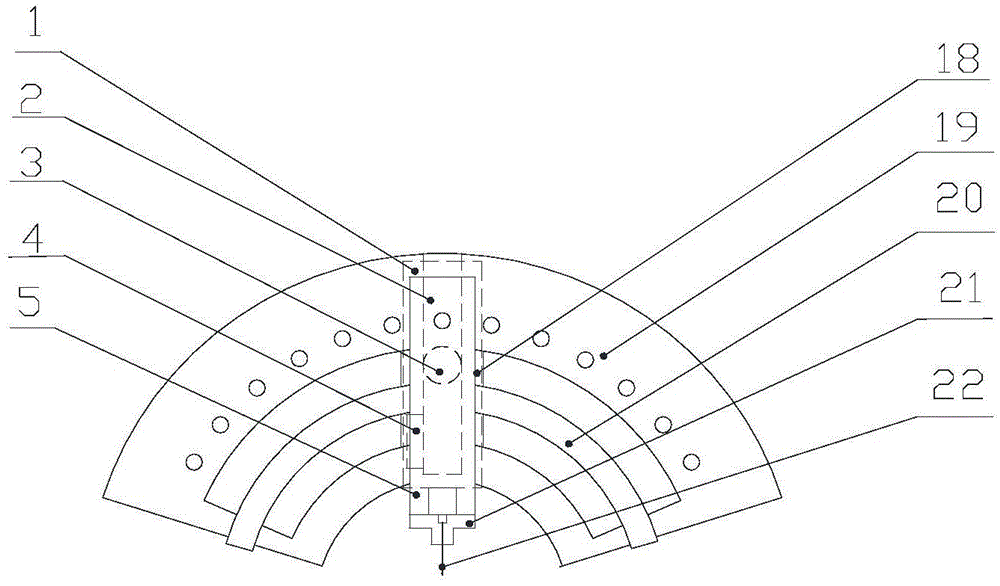

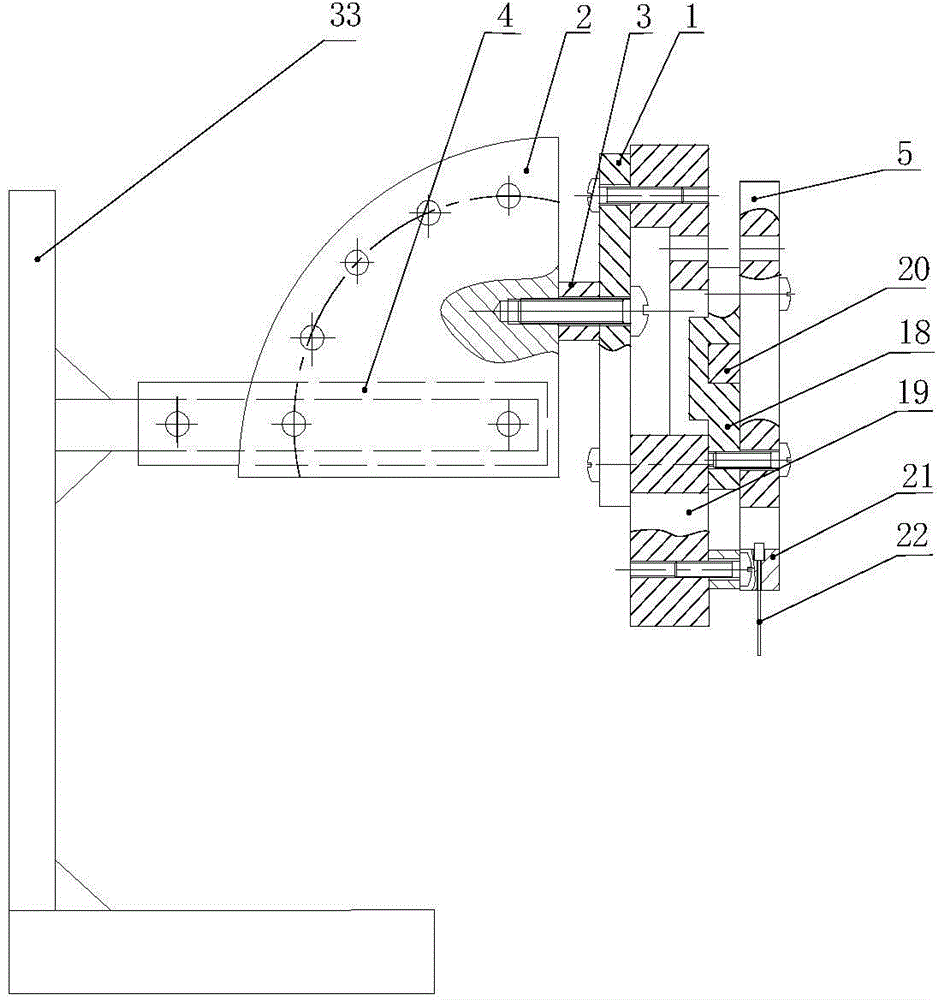

[0040] Specific implementation methods are described below with the aid of the accompanying drawings. Such as figure 1 , Figure 4 As shown, an electrostatic atomization cooling capacity evaluation device with adjustable nozzle space angle of the present invention includes an electrostatic atomization cooling system and a critical heat flux density and heat transfer coefficient measurement system. Among them, the electrostatic atomization cooling system consists of a large fan-shaped disk 19, a small fan-shaped disk 2, an adjustable handle 5, a pad 21, a guide rail 20, a first slider 18, a connecting pad 3, a gasket 1, a connecting handle 4, and a nozzle 22 , high-voltage electrostatic generator 24, high-voltage cable 23, lead A25, injection pump 35, silicon rubber tube 34, support 33 constitute. The critical heat flux density and heat transfer coefficient measurement system consists of copper rod 7, K-type thermocouple wire 6, K-type thermocouple 36, flange 8, heat insulati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com