Double-resonance vertical-cavity surface-emitting laser structure for generating terahertz wave and microwave

A vertical cavity surface emission, terahertz technology, applied in the direction of lasers, laser components, semiconductor lasers, etc., to achieve the effect of improving luminous efficiency and improving the uniformity of current expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

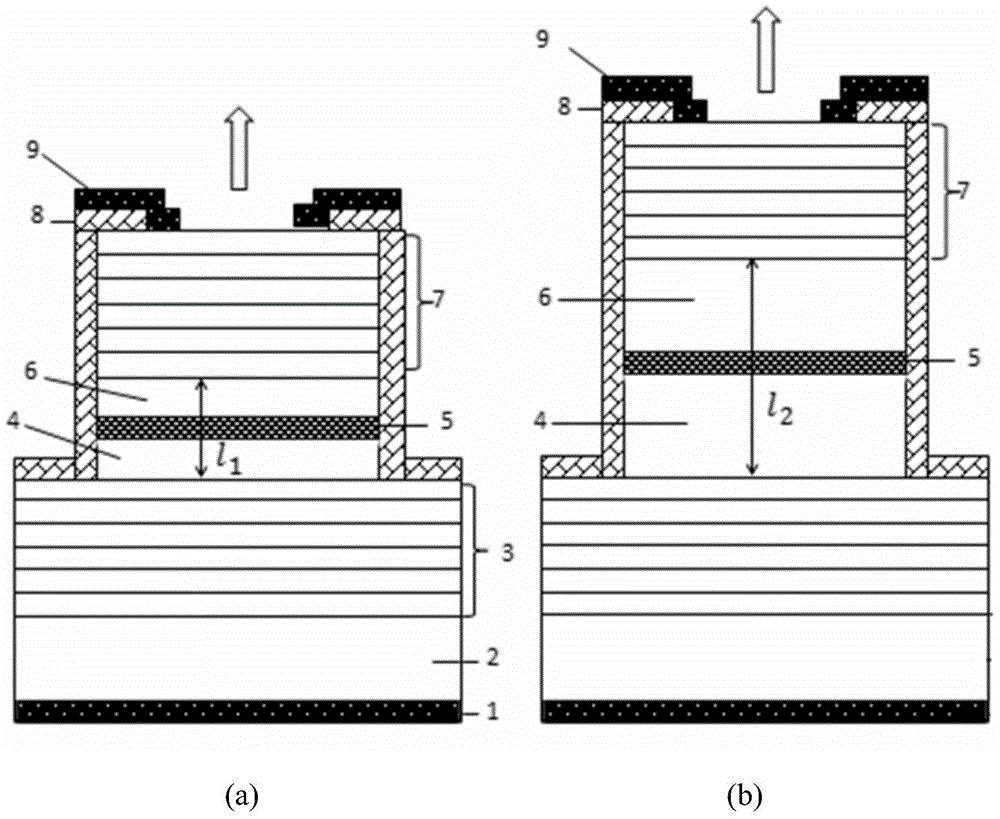

[0040] Figure 4 It is a schematic diagram of the manufacturing process of a dual-resonance vertical-cavity surface-emitting laser for generating terahertz waves or microwaves based on a 980nm GaAs-based substrate according to an embodiment of the present invention.

[0041] Step 1: Using the metal organic chemical vapor deposition method to sequentially grow epitaxial wafers, on the n-type GaAs substrate 2, sequentially grow 36 pairs of Al 0.12 Ga 0.88 As / Al 0.9 Ga 0.1 Distributed Bragg reflector 3 under As, n-type Al 0.3 Ga 0.7 As phase matching layer 4, 3 pairs of GaAs 0.92 P 0.08 (4nm) / Ga 0.83 In 0.17 As(6nm) strained quantum well gain region 5 and p-type Al 0.3 Ga 0.7 The As phase matching layer 6 constitutes an optical thickness of 12λ. The distributed feedback Bragg reflector 7 consists of 23.5 pairs of Al 0.9 Ga 0.1 As / Al 0.12 Ga 0.88 Composed of As, there is 30nm Al between the upper distributed feedback Bragg reflector 7 and the gain region 5 0.98 Ga ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com