SiO2 composite aerogel material loaded with photocatalyst and preparation method of SiO2 composite aerogel material

A composite aerogel, photocatalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., to achieve the effect of high pore volume and adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] ① Prepare silicic acid and TiCl respectively 4 Aqueous solution and tungstic acid solution.

[0072] Preparation of silicic acid: Mix 10ml of water glass and 60ml of deionized water evenly, and obtain silicic acid with pH=2-3 through ion exchange.

[0073] Prepare TiCl 4 Solution: Slowly add 250ml TiCl dropwise to 500g ice 4 solution, and then stirred for 30min, it was packed into a brown glass bottle, and its concentration was 3mol / L.

[0074] Preparation of tungstic acid: take 3.3g Na 2 WO 4 Add 20ml of deionized water to it, then add 20ml of Na 2 WO 4 The solution is ion-exchanged to obtain tungstic acid with a pH value of 1.5-3.

[0075] ② Preparation of SiO 2 Sols and gels.

[0076] Take 50ml of silicic acid and use concentrated ammonia water to adjust the pH value to about 13, then use 2.5mol / L dilute hydrochloric acid to adjust the pH value to between 7 and 8, let it stand for a while, and the silicic acid will form a gel within 5 minutes and have a cert...

Embodiment 2

[0084] Step 1., 2. are the same as Step 1. and 2. of Embodiment 1.

[0085] ③ Preparation of WO 3 -TiO 2 Sol, add 14.4ml of tungstic acid to 60ml of TiCl with a concentration of 3mol / L 4 In the solution, a white precipitate appeared, and after a period of stirring, the precipitate disappeared, forming a light yellow sol, and then continued to stir for 30 minutes; then added 30ml of concentrated ammonia water to it to promote hydrolysis.

[0086] Steps ④, ⑤, ⑥, ⑦ are the same as Steps ④, ⑤, ⑥, ⑦ of Embodiment 1.

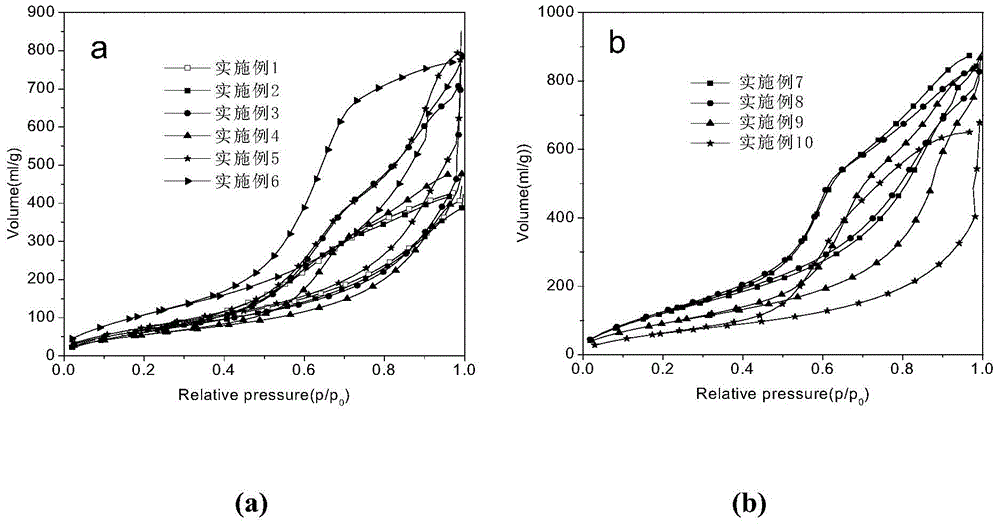

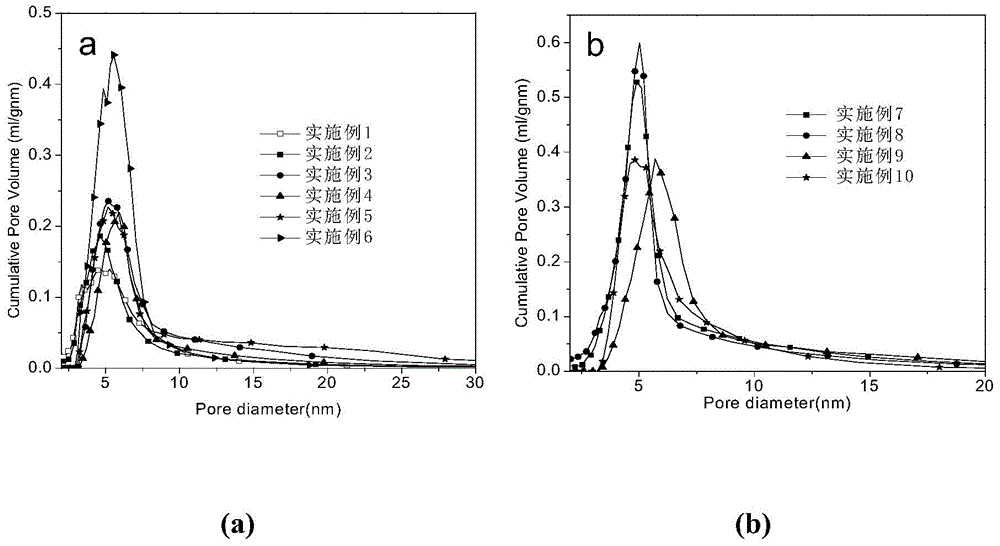

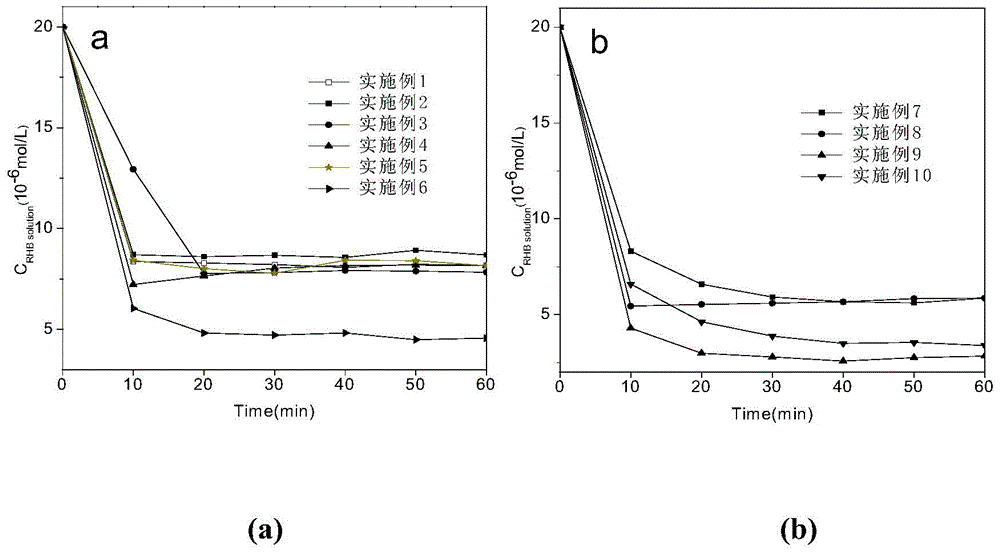

[0087] After determination, the WO prepared by this method 3 -TiO 2 / SiO 2 The composite airgel has a specific surface area of 280.9m 2 / g, the pore volume is 0.65cm 3 / g, the average pore diameter is 9.38nm. The adsorption rate of Rhodamine B was 56.52% for 1 hour in the dark room, and the degradation rate of Rhodamine B within 3 hours of light was as follows: Figure 5 -e.

Embodiment 3

[0089] Step 1., 2. are the same as Step 1. and 2. of Embodiment 1.

[0090] ③ Preparation of WO 3 -TiO 2 Sol, add 14.4ml of tungstic acid to 60ml of TiCl with a concentration of 3mol / L 4 In the solution, a white precipitate appeared, and after a period of stirring, the precipitate disappeared, forming a light yellow sol, and then continued to stir for 30 minutes; then 25ml of concentrated ammonia water was added to it to promote hydrolysis.

[0091] Steps ④, ⑤, ⑥, ⑦ are the same as Steps ④, ⑤, ⑥, ⑦ of Embodiment 1.

[0092] After determination, the WO prepared by this method 3 -TiO 2 / SiO 2 The composite airgel has a specific surface area of 279.6m 2 / g, the pore volume is 1.18cm 3 / g, the average pore diameter is 16.84nm. The adsorption rate of Rhodamine B was 59.18% for 1 hour in the dark room, and the degradation rate of Rhodamine B within 3 hours of light was as follows: Figure 5 -d.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com