Preparation method of deuteroethylene

A technology of deuterated ethylene and deuterated acetylene, which is applied in the field of isotope gas preparation, can solve the problems of restricting compound production technology research, high price, low conversion rate of deuterated ethylene, etc., and meets the requirements of equipment pressure resistance and is basically pollution-free and equipment. Low pressure resistance requirements and the effect of improving the utilization rate of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

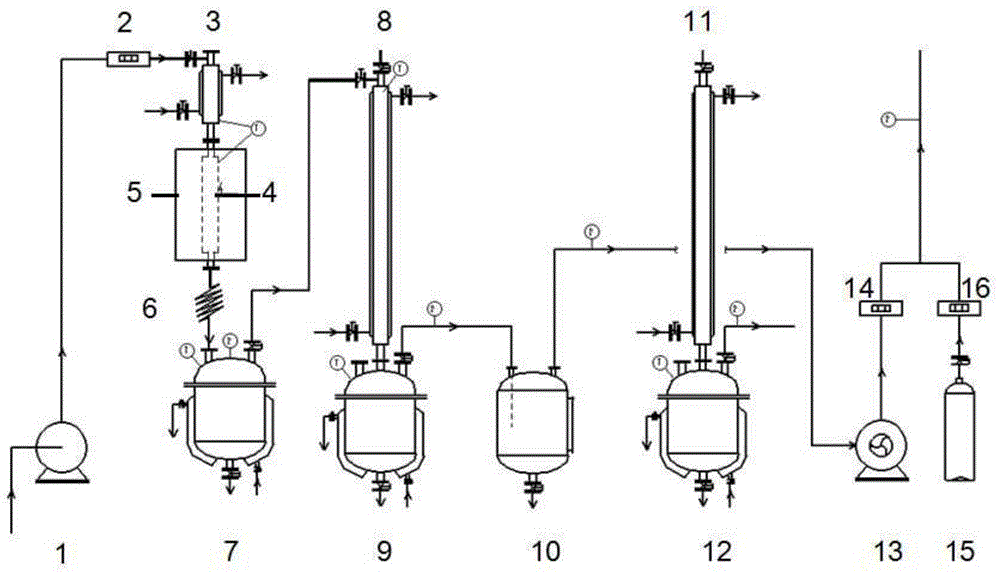

[0026] Carbide (CaC 2 ) and heavy water (D 2 O) reacts as starting material, generates deuterated acetylene (C 2 D. 2 ); deuterated acetylene in Cu-Ni / SiO 2 Under the catalysis of composite catalyst and deuterium gas (D 2 ) carries out deuterium addition reaction and makes deuterated ethylene (C 2 D. 4 ), the deuterated acetaldehyde and deuterium gas are in a volume ratio of 1:10 to 60.

[0027] In a specific embodiment, Cu-Ni / SiO 2 The active metal accounts for 1.75-2.00wt% of the total amount of oxides in the composite catalyst. In a specific embodiment, Cu-Ni / SiO 2 The composite catalyst is activated at high temperature (300-650°C, for example, 400°C). Those skilled in the art know that the above ratios and temperatures are not intended to limit the present invention, and their specific contents and temperatures can be adjusted according to actual needs.

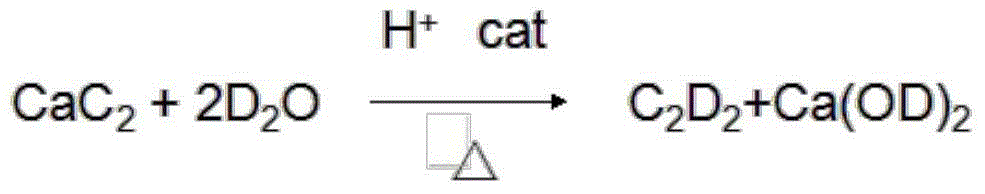

[0028] The reaction principle is as follows:

[0029] Deuterated acetylene synthesis

[0030]

[0031] T...

Embodiment 2

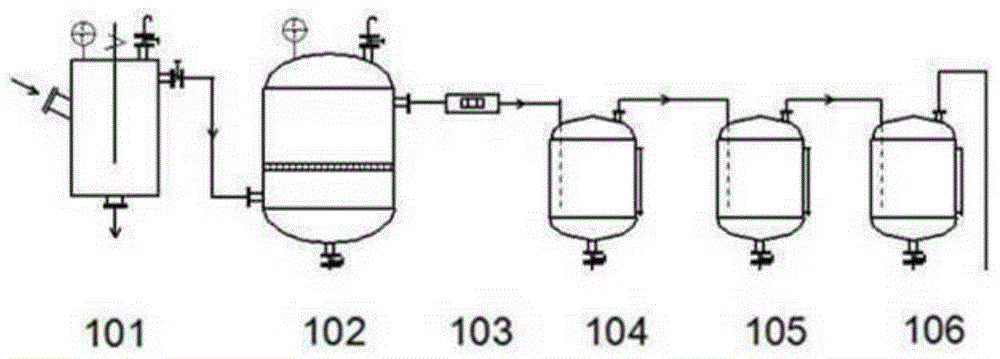

[0038] In a specific embodiment, the step of synthesizing deuterated acetylene is as follows: put calcium carbide qualified for processing into the deuterated acetylene generator 101 in excess. Under the condition of 0~100℃, add D dropwise at a uniform speed 2 O, maintain the pressure in the acetylene reactor 101 at 0-0.5Mpa. The acetylene release rate is adjusted through the outlet valve of the acetylene generator 101.

Embodiment 3

[0040] In a specific embodiment, in order to improve the purity of acetylene, the deuterated acetylene from the acetylene generator 101 passes through the buffer tank 102 and the flow meter 103, and then passes through the neutralization tanks 104-106 sequentially, using D 2 O, D 2 SO 4 and Na 2 S 2 o 3 The deuterated acetylene is washed with the solution, and the dust, NH 3 , S, As and other impurities.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com