A kind of modified talc used for fire-proof and flame-retardant coating and its manufacturing method

A technology of fire-resistant and flame-retardant coatings and talc, applied in the direction of fire-resistant coatings, chemical instruments and methods, coatings, etc., can solve the problems of little contribution to the improvement of the overall performance of the final coating product and single functionality, and achieve good fusion and dispersion and property retention, strong hydrophilicity, and life-prolonging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

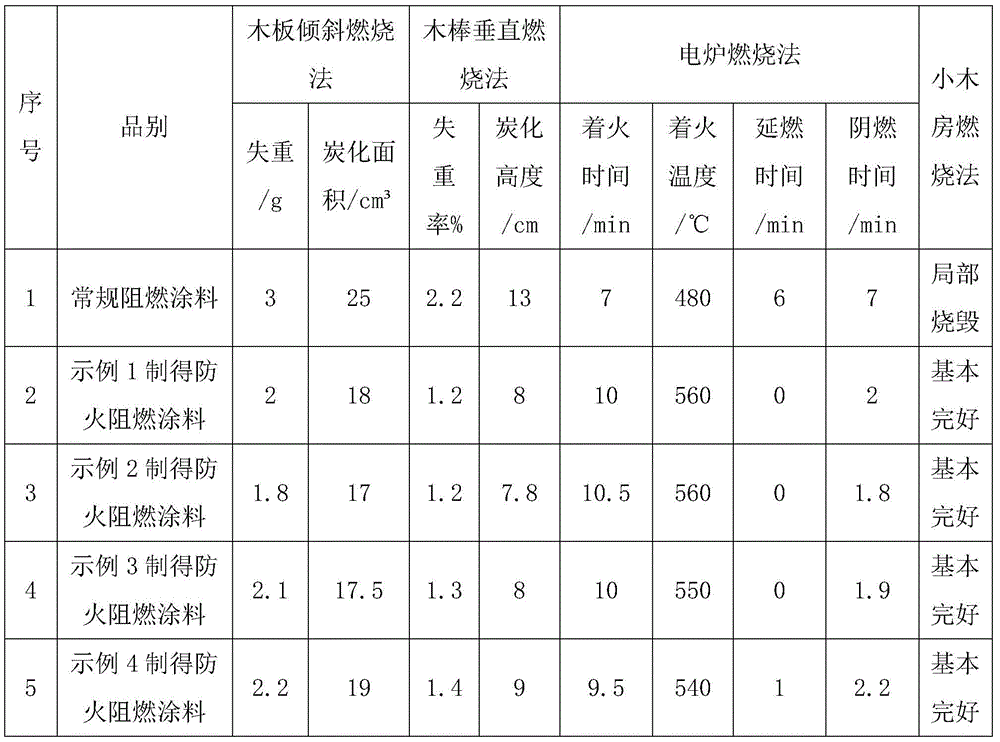

Examples

Embodiment Construction

[0024] Below in conjunction with embodiment the present invention is further described:

[0025] The following examples describe the present invention in detail. These examples are only to describe the best embodiment of the present invention, and do not limit the scope of the present invention.

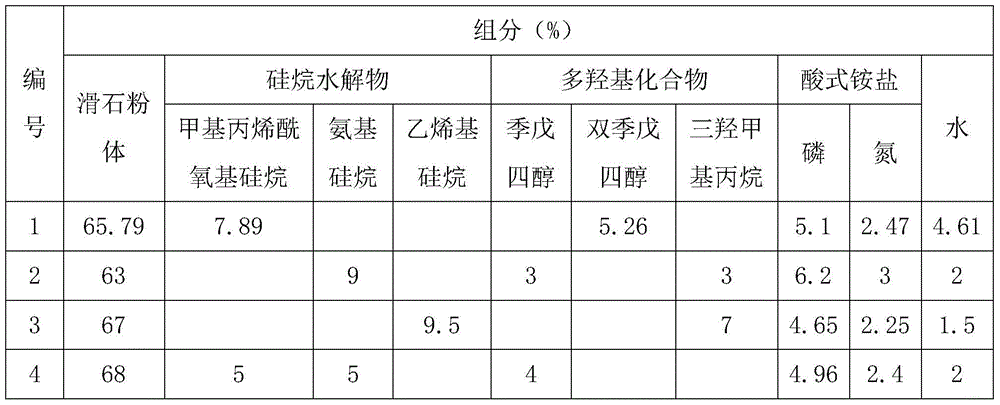

[0026] A modified talc used for fire-resistant and flame-retardant coatings. The modified talc is white prismatic granular, and its main mineral component is natural talc with a purity of ≥75%. The mass percentage of each component in the product is: 63-68 % talcum powder, 4%-8% polyol, 15-20% acid ammonium salt, 6-10% silane hydrolyzate, moisture≤10%;

[0027] Table 1: Implementation Example Component Composition

[0028]

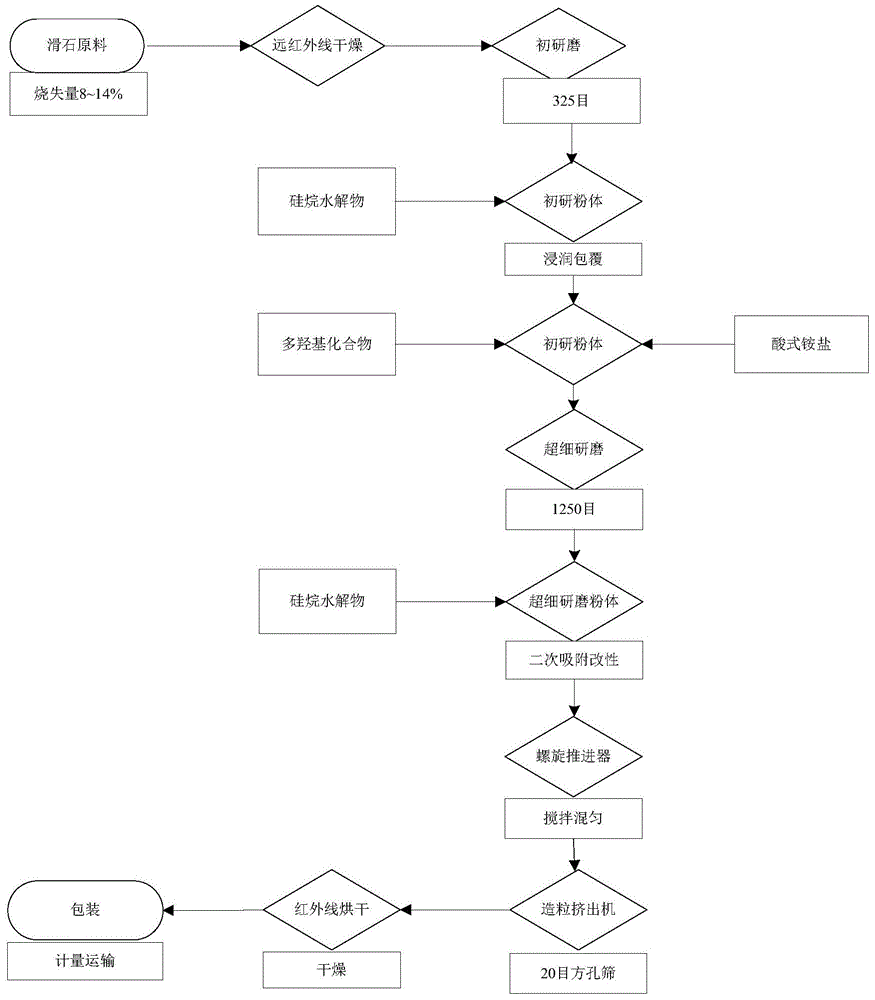

[0029] See figure 1 , embodiment 1 is used for the modified talc manufacture method of fireproof flame retardant coating, comprises the following steps:

[0030] 1) Select a muffle furnace, detect the loss on ignition at 1050°C, and ensure that the loss on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com