Fire-resistant coating fluid and coating process for expanded polystyrene insulation material

A technology of expanded polystyrene and thermal insulation materials, applied in the direction of fireproof coatings, coatings, epoxy resin coatings, etc., can solve problems such as increased bulk density, decreased thermal insulation performance, and products that do not meet national standards, so as to inhibit thermal decomposition and improve The effect of flame retardant and fire prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

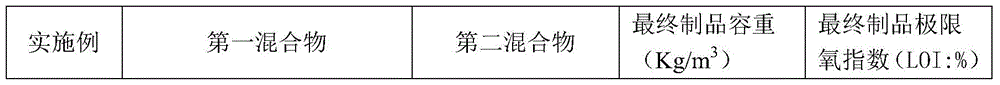

Embodiment 1

[0057] Make the first mixture: take 60.00g of dimethyl methylphosphonate (DMMP), add 30.00g of resorcinol bis[bis(2,6-dimethylphenyl)phosphate] (PX200), and stir at room temperature until the solid flame retardant is completely dissolved to obtain the first mixture.

[0058] Take 100.00g of pre-made EPS beads (loose density 15Kg / m 3 ), add 30.00g of the first mixture, stir and coat evenly; then add 70.00g of the second mixture, stir and coat evenly again, and dry at 50-55°C at low temperature to obtain flame-retardant thermosetting coated EPS beads.

[0059] After the bead is formed according to the conventional scale pressing process, the bulk density is 30Kg / m 3 The EPS board has a limiting oxygen index (LOI value) of 28.5.

Embodiment 2

[0061] Make the first mixture: Take 60.00g of diethyl ethylphosphonate (DEEP), add 30.00g of resorcinol bis[bis(2,6-dimethylphenyl)phosphate] (PX200), and stir at room temperature until the solid flame retardant is completely dissolved to obtain the first mixture.

[0062] Take 100.00g of pre-made EPS beads (loose density 15Kg / m 3 ), add 30.00g of the first mixture, stir and coat evenly; then add 70.00g of the second mixture, stir and coat evenly again, and dry at 50-55°C at low temperature to obtain flame-retardant thermosetting coated EPS beads.

[0063] After the bead is formed according to the conventional scale pressing process, the bulk density is 30Kg / m 3 The EPS board has a limiting oxygen index (LOI value) of 28.2.

Embodiment 3

[0065] Make the first mixture: Take 60.00g of dimethyl propyl phosphonate (DMPP), add 30.00g of resorcinol bis[bis(2,6-dimethylphenyl)phosphate] (PX200), and stir at room temperature until the solid flame retardant is completely dissolved to obtain the first mixture.

[0066] Take 100.00g of pre-made EPS beads (loose density 15Kg / m 3 ), add 30.00g of the first mixture, stir and coat evenly; then add 70.00g of the second coating mixture, stir and coat evenly again, and dry at 50-55°C at low temperature to obtain flame-retardant thermosetting coated EPS beads.

[0067] After the bead is formed according to the conventional scale pressing process, the bulk density is 30Kg / m 3 The EPS board has a limiting oxygen index (LOI value) of 29.4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com