A kind of sulfonate surfactant suitable for weak alkali three-component compound flooding and its application

A surfactant and ternary composite technology, which is applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of formation damage caused by strong alkali, and achieve controllable product composition, enhanced oil recovery, and preparation technology. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] This kind of sulfonate surfactant suitable for weak base ASP flooding is made of C 12 ~C 24 Alkylaryl compounds, C 20 ~C 28 After mixing the mixed α-olefins, carry out sulfonation reaction, aging hydrolysis, then add alcohol, and then neutralize. Alkylaryl sulfonate and α-alkenyl sulfonate, wherein the average equivalent weight of alkylaryl sulfonate is 400~500, the specific preparation method is as follows:

[0019] ⑴Choose alkylbenzene, C with an average molecular weight of 310 20 ~C 28 Mixed α-olefins, mixed as raw materials for sulfonation, wherein the weight percentage of alkylbenzene is 50%~90%, C 20 ~C 28 The weight percentage of mixed α-olefins is 10%~50%; (2) Sulfonation reaction: use falling film sulfonator to carry out sulfonation reaction on the above mixed sulfonation raw materials, the reaction process conditions are: the molar ratio of reaction raw materials is 1.0~2.0:1, sulfonation reaction temperature is 30℃~80℃, SO 3 The gas concentration is 2...

Embodiment 2

[0022] The specific preparation method of this sulfonate surfactant suitable for weak alkali three-component compound flooding is as follows:

[0023] ⑴Choose alkylxylene and C with an average molecular weight of 310 20 ~C 28 Mixed α-olefins, mixed as raw materials for sulfonation, wherein the weight percentage of alkylxylene is 65%~85%, C 20 ~C 28 The weight percentage of mixed α-olefins is 15%~35%; (2) Sulfonation reaction: use falling film sulfonator to carry out sulfonation reaction on the above mixed sulfonation raw materials, the reaction process conditions are: the molar ratio of reaction raw materials is 1.3~1.45:1, sulfonation reaction temperature is 45℃~55℃, SO 3 The gas concentration is 4.0g / L~4.5%g / L, the total amount of protective air volume is controlled at 2000L / h, the ratio of primary air to secondary air is 500 / 1500L / h~600 / 1400L / h; the molar ratio of reaction raw materials is SO 3 The molar ratio with the mixed sulfonated raw material;

[0024] (3) Aging...

Embodiment 3

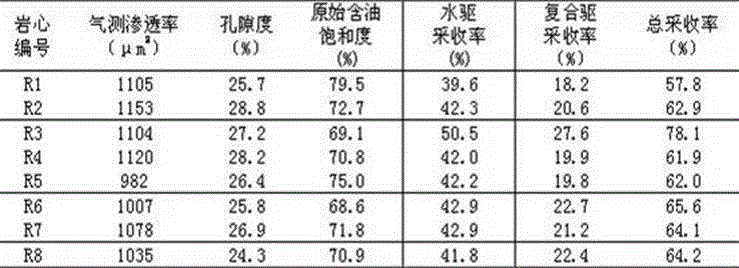

[0026] It is suitable for performance experiment of sulfonate surfactant used in weak base ASP flooding.

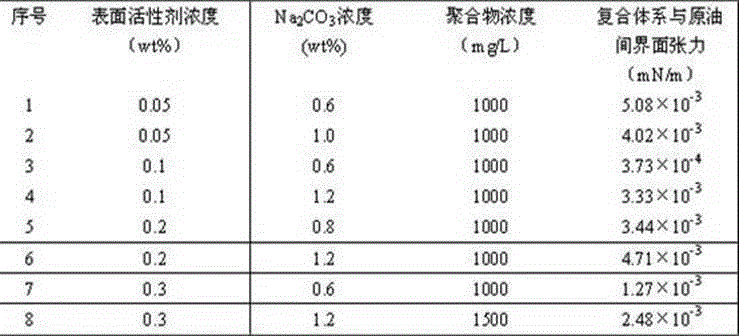

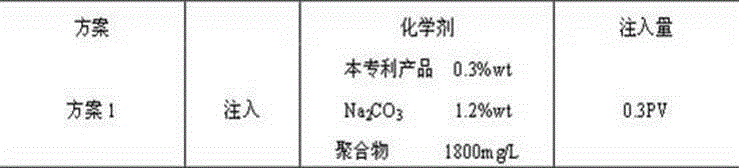

[0027]Utilize the sulfonate surfactant suitable for weak base three-way compound oil flooding prepared in Example 1, prepare the weak base three-way compound system as shown in Table 1, the method is: surfactant (effective concentration) and alkali All are first prepared into 5wt% mother liquor. The polymer is prepared into a 5000mg / L solution by advanced treatment sewage, and the polymer solution is stirred for 2-3 hours at a speed of 1000RPM, and matured for 12 hours. When preparing the ternary system, dilute the 5000mg / L solution with sewage to the corresponding concentration. When preparing the ternary system, according to the principle that the lesser amount is added first and the surfactant and alkali should be added separately, the order of adding various chemical agents should be: surfactant-polymer-sewage-alkali. Weighing should be accurate to 0.001g, and the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com