A method for improving the sand-carrying capacity of fracturing fluid and its fiber-containing fracturing fluid

A fracturing fluid and cleaning fracturing fluid technology, applied in chemical instruments and methods, drilling compositions and other directions, can solve the problem that the fracturing fluid is difficult to meet the requirements, improve the sand-carrying capacity, reduce the dosage, and be easy to break glue effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

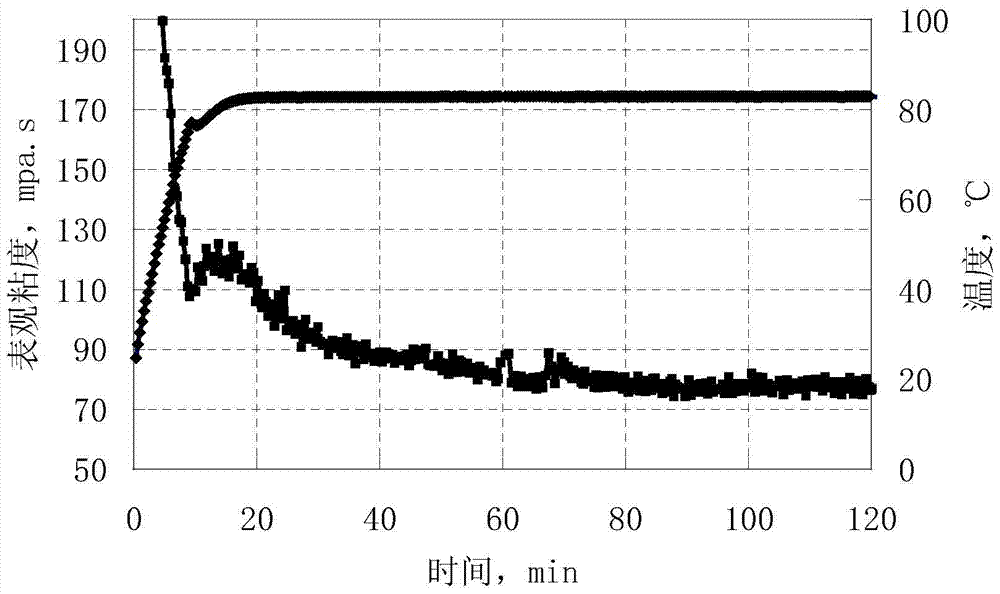

[0031] This embodiment provides a fiber-containing guar gum fracturing fluid, the preparation method of which is as follows:

[0032] Step 1: under stirring condition, add 0.2 weight part of thickener hydroxypropyl guar gum (China Petroleum Substances Kunshan Company), 0.12 weight part of sodium carbonate, 0.1 weight part of potassium chloride to 100 weight parts of water, then stir for 20min, Obtain guar thickener aqueous solution;

[0033]Step 2: During the fracturing operation, under stirring conditions, add 0.2 parts by weight of crosslinking agent FAL-120 (Langfang Vanke Petroleum and Natural Gas Technology Engineering Co., Ltd.) Ammonium sulfate, obtains guar gum fracturing fluid (does not contain fiber guar gum fracturing fluid);

[0034] Step 3: Add 0.5 parts by weight polyacrylonitrile fiber (the tensile strength is 100MPa, and the real density is 0.98g / cm2 in the above-mentioned guar gum fracturing fluid) 3 , the length is 5 mm, and the diameter is 78 μm), and stir...

Embodiment 2

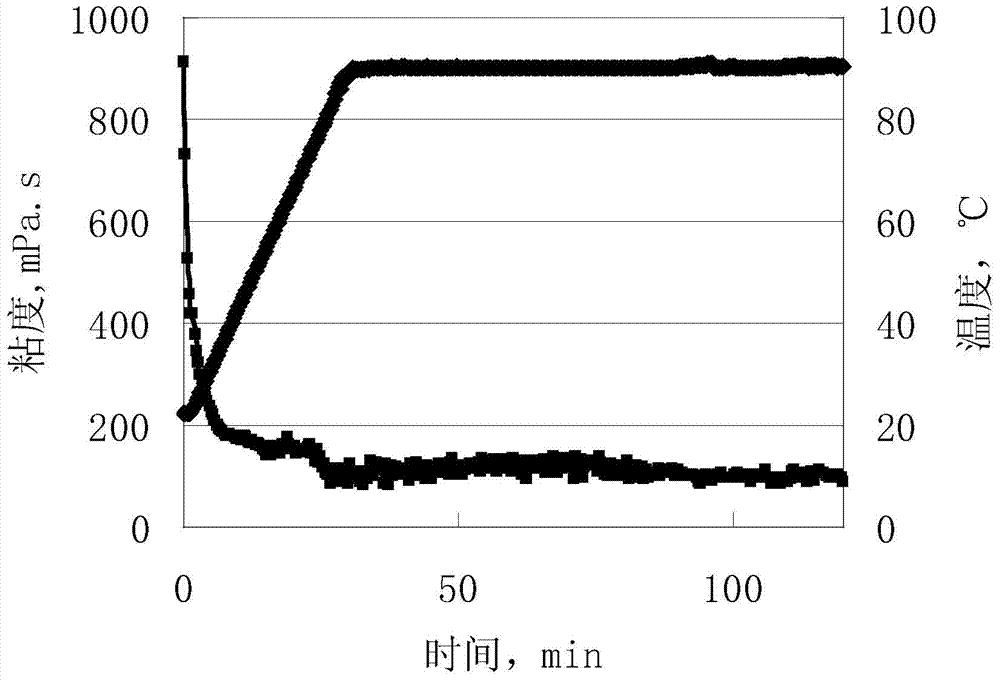

[0037] This embodiment provides a fiber-containing polymer fracturing fluid, the preparation method of which is as follows:

[0038] Step 1: under stirring condition, add 0.3 weight part thickening agent nonionic synthetic polymer FA92 (Langfang Vanke Petroleum Technology Engineering Co., Ltd.), 0.02 weight part cross-linking regulator FAH-2 (Langfang City) to 100 weight parts water Vanke Petroleum and Natural Gas Technology Engineering Co., Ltd.), 0.1 parts by weight of potassium chloride, and then stirred for 20min to obtain an aqueous polymer thickener solution;

[0039] Step 2: During the fracturing operation, under stirring conditions, add 0.3 parts by weight of crosslinking agent FAG18 (Langfang Vanke Petroleum and Natural Gas Technology Engineering Co., Ltd.), 0.03 parts by weight of gel breaker ammonium persulfate to the above-mentioned thickener aqueous solution , to obtain polymer fracturing fluid (excluding fiber polymer fracturing fluid);

[0040] Step 3: Add 0.35...

Embodiment 3

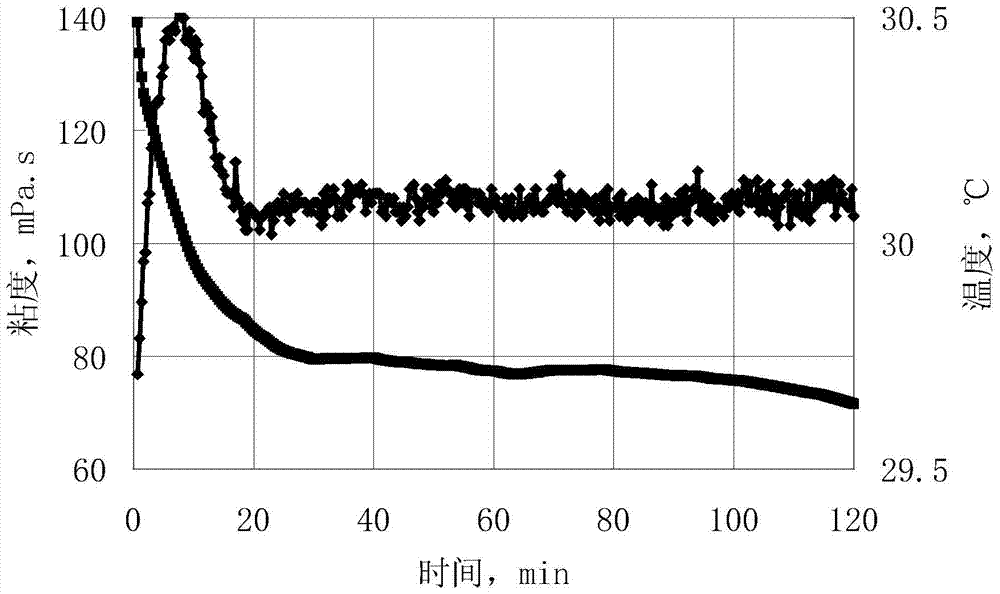

[0043] This embodiment provides a fiber-containing clean fracturing fluid, the preparation method of which is as follows:

[0044] Step 1: under stirring condition, add 0.1 weight part of thickener gemini cationic surfactant SF-A (Langfang City Vanke Petroleum and Natural Gas Technology Engineering Co., Ltd.) to 100 weight parts of water, 0.1 weight part of sodium chloride, then stir for 20min, Get clean fracturing fluid (clean fracturing fluid without fibers);

[0045] Step 2: During the fracturing operation, under stirring conditions, add 0.4 parts by weight of gel breaker SF-C (Langfang Vanke Petroleum and Natural Gas Technology Engineering Co., Ltd.), 0.5 parts by weight of soluble polyethylene fiber to the above-mentioned clean fracturing fluid (The tensile strength is 110MPa, the real density is 1.12g / cm 3 , with a length of 8 mm and a diameter of 102 μm) were stirred and mixed evenly to obtain a fiber-containing clean fracturing fluid.

[0046] The fiber-containing cl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com