Iron-based compound oxygen carrier and preparation method thereof

An oxygen carrier, iron-based technology, applied in chemical instruments and methods, chemical/physical processes, fuel additives, etc. Oxygen capacity is poor, the scope of use is limited, etc., to achieve the effect of high reactivity and tar removal rate, convenient industrial continuous production, and unique formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

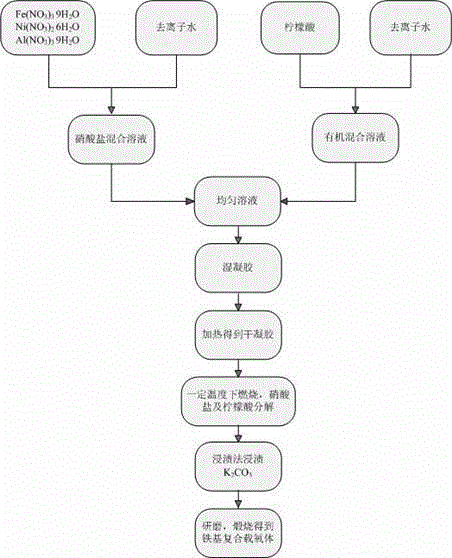

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: An iron-based composite oxygen carrier is prepared by the following method:

[0029] Take 40.40 g Fe(NO 3 ) 3· 9H 2 O was placed in a 500 mL beaker, 80 mL of deionized water was added, and then the beaker was placed on a magnetic stirrer with a constant temperature water bath for stirring; 25.21g of Al(NO 3 ) 3· 9H 2 O and 3.66 g Ni(NO 3 ) 2· 6H 2O was added to a 100 mL beaker, and 50 mL of deionized water was added and stirred. Al(NO 3 ) 3· 9H 2 O and Ni(NO 3 ) 2· 6H 2 The mixture of O was added to Fe(NO 3 ) 3· 9H 2 O solution, and stirred at 45°C until completely dissolved. Add 36.43 g of citric acid into a 100 mL beaker, and add 40 mL of deionized water to stir until the citric acid is completely dissolved, then add it to the above mixed salt solution, and stir the mixture at 72°C for 8 hours to form a coagulate gel, and then place the wet gel at room temperature for 18 hours to form a wet gel. The wet gel was heated at 75°C for 6...

Embodiment 2

[0031] Embodiment 2: get 40.40 g Fe(NO 3 ) 3· 9H 2 O was placed in a 500 mL beaker, 80 mL of deionized water was added, and then the beaker was placed on a magnetic stirrer with a constant temperature water bath for stirring; 25.21 g of Al(NO 3 ) 3· 9H 2 O and 3.66 g Ni(NO 3 ) 2· 6H 2 O was added to a 100 mL beaker, and 50 mL of deionized water was added and stirred. Al(NO 3 ) 3· 9H 2 O and Ni(NO 3 ) 2· 6H 2 The mixture of O was added to Fe(NO 3 ) 3· 9H 2 O solution, and stirred at 50°C until completely dissolved. Add 36.43 g of citric acid into a 100 mL beaker, add 40 mL of deionized water and stir until the citric acid is completely dissolved, then add it to the above mixed salt solution, and stir the mixture at 75 °C for 6 hours to form a coagulate gel, and then place the wet gel at room temperature for 18 hours to form a wet gel. The wet gel was heated at 70°C for 8 hours, and then heated at 105°C for 14 hours to form a dry gel. Take out the dry gel,...

Embodiment 3

[0034] Embodiment 3: An iron-based composite oxygen carrier is prepared by the following method:

[0035] Take 40.40g Fe(NO 3 ) 3 9H 2 O into a 500 ml beaker, add 80 ml of deionized water, and then place the beaker on a magnetic stirrer with a constant temperature water bath for stirring. Then put 25.21 g Al(NO 3 ) 3 9H 2 O and 3.66 gNi(NO 3 ) 2 ·6H 2 O was added to a 100 ml beaker, and 50 ml of deionized water was added and stirred. Then Al(NO 3 ) 3 9H 2 O and Ni(NO 3 ) 2 ·6H 2 Add Fe(NO 3 ) 3 9H 2 O solution, and stirred at 45°C until completely dissolved. Take 36.43 g of citric acid and add it to a 100 ml beaker, add 40 ml of deionized water and stir until the citric acid is completely dissolved, and then add it to the above mixture. The mixture was stirred at 72° C. for 8 hours to form a gel, and then the wet gel was left at room temperature for 18 hours to form a wet gel. The wet gel was heated at 75°C for 5 hours, and then heated at 110°C for 13 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com