Composite door board

A door panel and panel technology, which is applied in the field of composite door panels, can solve problems such as waste, and achieve the effects of low price, simple production process and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing example, the present invention is described in further detail:

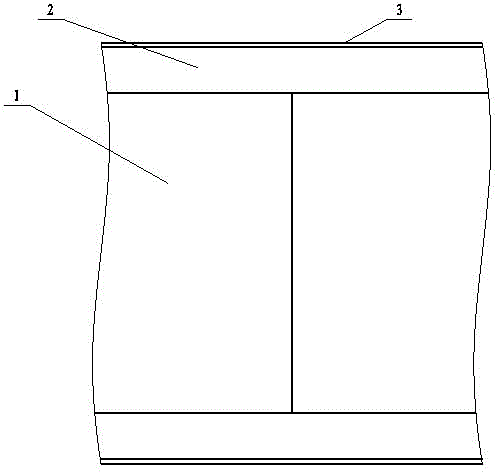

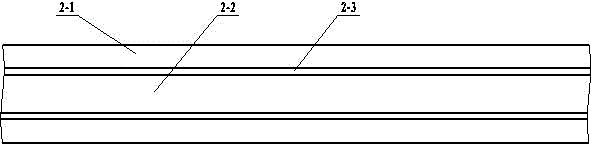

[0015] like figure 1 and figure 2 The present embodiment shown includes a panel, and the panel includes a core formed by splicing two or more finger-jointed slats 1, and a layer of composite Artificial board 2, this artificial board comprises two layers of base material layer 2-1, is provided with sound insulation layer 2-2 between two base material layers, and this sound insulation layer is the foam layer of old foam mattress, base material layer 2-1 Adhesive with glue 2-3 between sound insulation layer 2-2;

[0016] The manufacture method of door panel of the present invention comprises the steps:

[0017] A. Process the recycled old foam mattress, take out the foam layer from the old foam mattress, cut it into a size of 1000*2000mm, prepare two pieces of 1000*2000mm plywood, and paint on one side of the two plywood respectively Urea-formaldehyde resin,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com