System for utilizing oil field produced wastewater to prepare high-dryness steam for steam flooding

A technology of oil extraction wastewater and high dryness, which is applied in the steam generation method using heat carrier, exploitation fluid, earthwork drilling, etc., can solve the problems of high power consumption, low process water production rate, complicated and lengthy pretreatment process, etc. Achieve the effects of no secondary pollution, reduced power consumption costs, and loose pretreatment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the above and other objects, features and advantages of the present invention more comprehensible, preferred embodiments are listed below and described in detail in conjunction with the accompanying drawings.

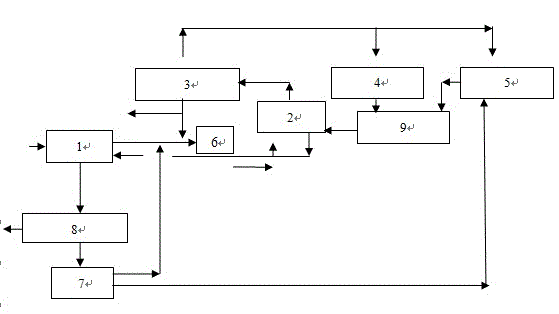

[0016] Such as figure 1 as shown, figure 1 It is a structural diagram of a system for preparing high-dryness steam for steam flooding by using oil production wastewater according to the present invention. The system for preparing high-dryness steam from oil extraction wastewater for steam flooding consists of a preheater 1, an evaporator 2, a steam-water separator 3, a steam compressor 4, a steam ejector 5, a circulation pump 6, a flash tank 7, The steam injection boiler system 8 and the steam mixer 9 are composed.

[0017] The preheater 1 receives the heavy oil produced water, heats the heavy oil produced water to nearly 100°C, discharges it into the outlet pipe of the steam-water separator 3, and pumps it into the evaporator 2 through the cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com