Stone exploiting method

A technology of stone and working medium, which is applied in the mining of open-pit mines, earthwork drilling, special mining, etc., can solve the problems of serious noise and dust pollution, small diameter of drilling holes, inconvenient movement, etc., to simplify operation steps and reduce labor intensity. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

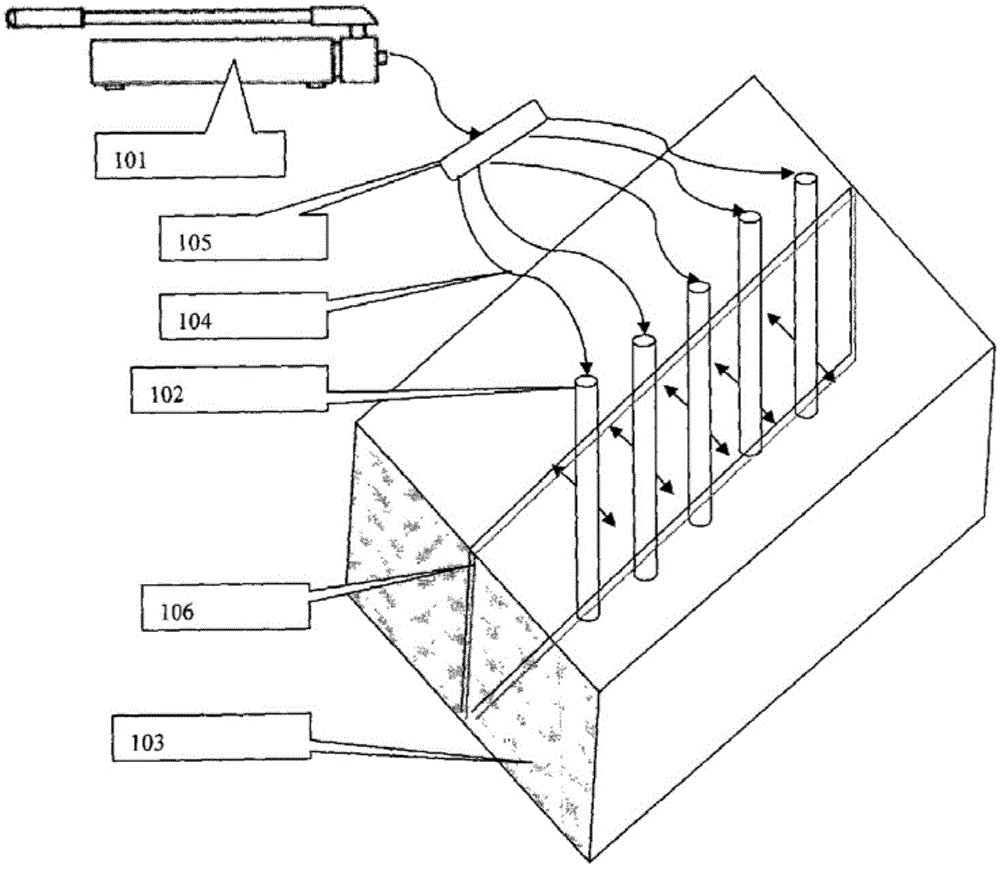

Image

Examples

Embodiment 1

[0027] The diameter of said drill bit in the above-mentioned method is 30 millimeters. The distance between two adjacent drill holes is 400mm. The working flow rate of the manual hydraulic pump is 1 liter / minute. The pressure applied to the working medium is 80MPa, the inner layer of the hydraulic pipe is the inner layer of post-crosslinked polyethylene resin, the outer layer of the hydraulic pipe is the outer layer of polyvinyl chloride resin grafted with acrylic acid, and the reinforced layer of the hydraulic pipe is It is a nanometerized polyester fiber reinforcement layer. The hydraulic pipe reinforcement layer is two layers of winding reinforcement layers with opposite winding directions crossing left and right. The inner diameter of the hydraulic pipe is 3mm and the outer diameter is 12mm.

Embodiment 2

[0029] The method described in the above-mentioned embodiment 1 is basically the same, the difference is that the diameter of said drill bit is 43 millimeters. The distance between two adjacent drilling holes is 800mm. The working flow rate of the manual hydraulic pump is 1.5 liters / minute. The pressure applied to the working medium is 100 MPa, the inner layer of the hydraulic pipe is an inner layer of polyamide resin, the outer layer of the hydraulic pipe is an outer layer of polyurethane resin, the reinforced layer of the hydraulic pipe is a carbon fiber reinforced layer, and the reinforced layer of the hydraulic pipe is It is 5 layers of winding reinforcing layers with opposite winding directions crossing left and right. The inner diameter of the hydraulic pipe is 4mm and the outer diameter is 10mm.

Embodiment 3

[0031] The method described in the above-mentioned embodiment 2 is basically the same, and the difference is that the diameter of the drill bit is 63 millimeters. The distance between two adjacent drilling holes is 1000mm. The working flow rate of the manual hydraulic pump is 2 liters / minute. The pressure applied to the working medium is 110MPa, the inner layer of the hydraulic pipe is an inner layer of post-crosslinked polyethylene resin, the outer layer of the hydraulic pipe is an outer layer of ultra-high molecular weight polyethylene, and the reinforcement layer of the hydraulic pipe is a steel wire winding reinforcement layer , the hydraulic pipe reinforcement layer is a 3-layer winding reinforcement layer with opposite winding directions crossing left and right, the inner diameter of the hydraulic pipe is 3.5mm, and the outer diameter is 8mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com