Patch special for esophageal hiatus hernia

A technology of hiatal hernia and mesh, which is applied in the field of hernia mesh, can solve problems such as failure to satisfy hiatal hernia, corrosion of esophagus and stomach, and non-adaptability of the mesh, so as to strengthen the edge of esophageal hiatus and have good tissue adaptability , fixed easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

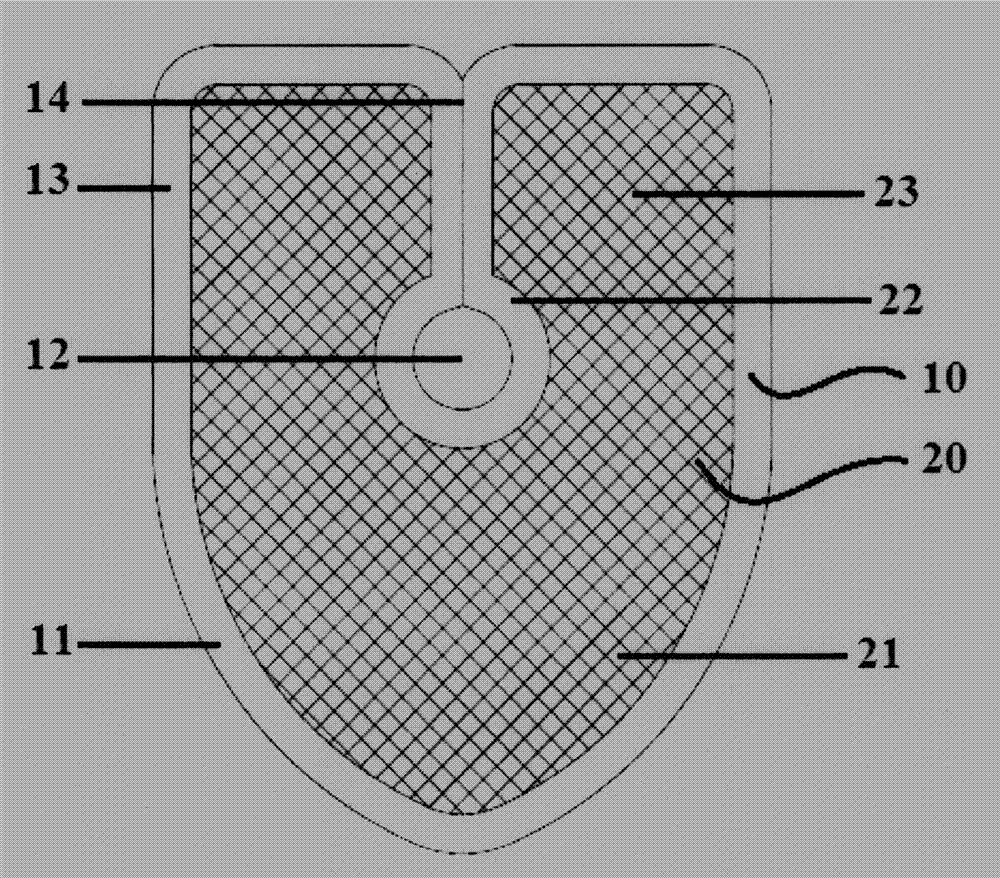

[0022] Such as figure 1 As shown, the special patch for hiatal hernia described in this embodiment includes a poly L-lactide-caprolactone (PLCL) absorbable layer 10, and a mesh poly Propylene non-absorbable layer 20; in application, the outer surface of said absorbable layer 10 is placed facing the stomach, and the outer surface of said non-absorbable layer 20 is placed facing the diaphragm. Because the polypropylene network structure is conducive to the growth of tissues, it can quickly induce the formation of scars in the surrounding tissues and achieve the effect of strengthening the edge of the esophageal hiatus. Poly L-lactide-caprolactone (PLCL) has good biocompatibility and stability, and can avoid the adhesion or formation of scar tissue between the patch and the abdominal viscera and omentum, which will affect the movement of the esophagus and cause abdominal viscera shift. The area of the absorbable layer is larger than that of the non-absorbable layer, but both ...

Embodiment 2

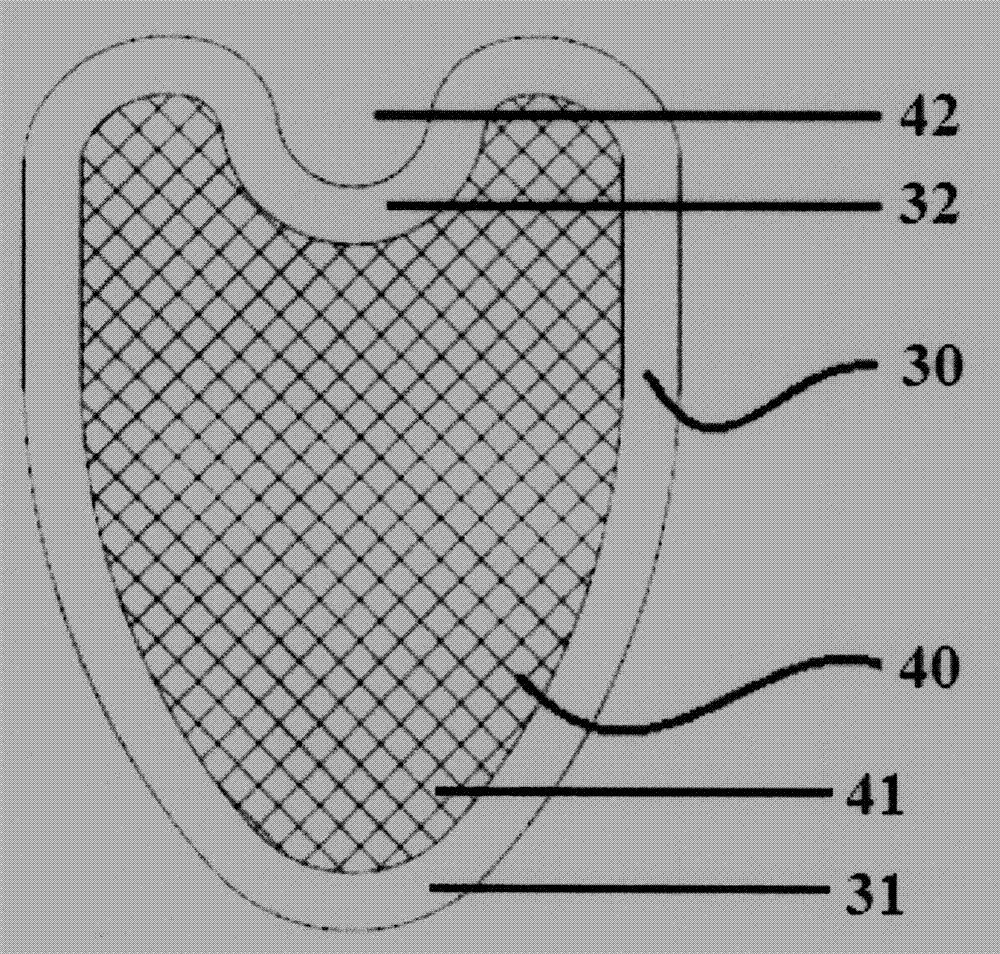

[0024] Such as figure 2 As shown, the special patch for hiatal hernia described in this embodiment includes a poly L-lactide-caprolactone (PLCL) absorbable layer 30, and a mesh poly Propylene non-absorbable layer 40; in application, the outer surface of said absorbable layer 30 is placed facing the stomach, and the outer surface of said non-absorbable layer 40 is placed facing the diaphragm. Because the polypropylene network structure is conducive to the ingrowth of tissues, it can quickly induce the formation of scars in the surrounding tissues and achieve the effect of strengthening the edge of the esophageal hiatus. Poly L-lactide-caprolactone (PLCL) has good biocompatibility and stability, and can avoid the adhesion or formation of scar tissue between the patch and the abdominal viscera and omentum, which will affect the movement of the esophagus and cause abdominal viscera shift. The area of the absorbable layer is larger than that of the non-absorbable layer, but bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com