A kind of preparation method of nano hydrotalcite

A hydrotalcite and nano-technology, which is applied in the field of preparation of nano-hydrotalcites, can solve problems such as microchannel reactor blockage, and achieve the effects of short residence time, uniform particle size, and narrow distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

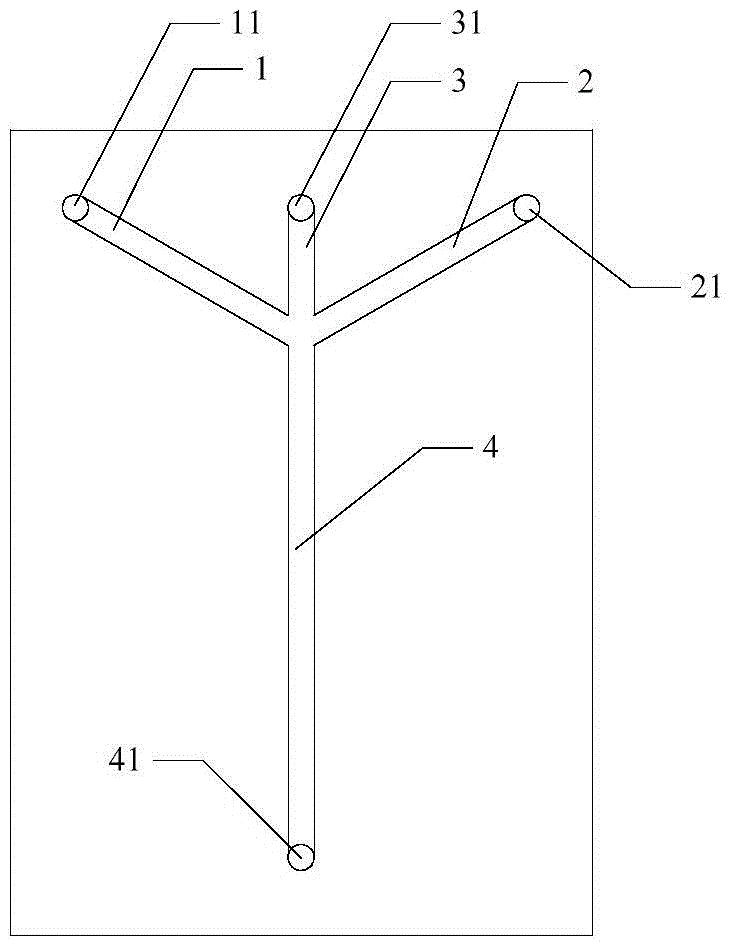

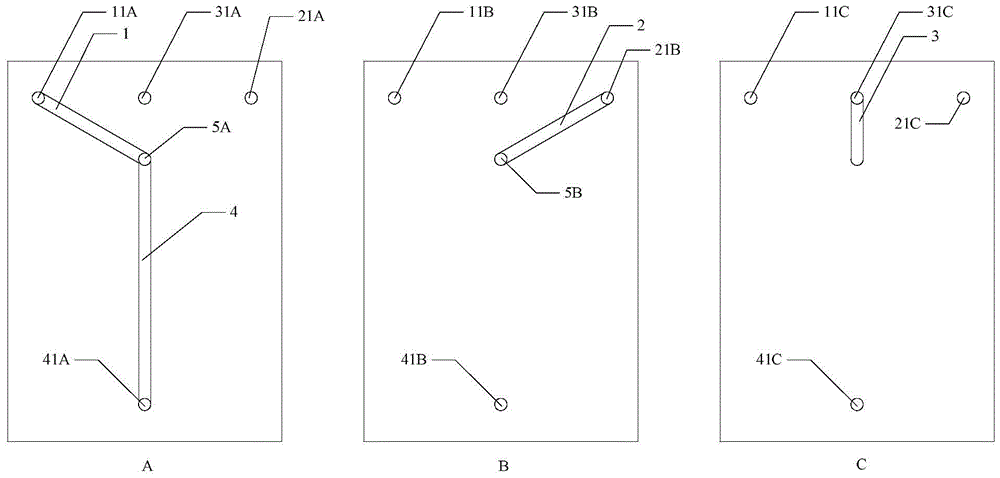

Method used

Image

Examples

Embodiment 1

[0028] Weigh 48.1g of Mg(NO 3 ) 2 ·6H 2 O and 23.4g of Al(NO 3 ) 3 9H 2 O, configured as 500ml of an aqueous solution with a total concentration of metal ions of 0.5mol / L. Weigh 16g of NaOH and 13.25g of Na 2 CO 3 configured as OH - and CO 3 2- 500ml of aqueous solution with a total concentration of 1.05mol / L. Air is selected as the gas, and the flow rate is 100ml / min. Both the metal salt solution and the alkali solution enter the microchannel reactor at a flow rate of 150ml / min to contact, mix and react, and the reaction temperature is 80°C. Take part of the precipitate and put it into a hydrothermal reactor, and treat it at 150°C for 6h. The precipitate after hydrothermal treatment was fully washed with deionized water, and the precipitate obtained after centrifugation was nano-carbonate-type MgAl hydrotalcite. The XRD and TEM characterization results were as follows: image 3 , Figure 4 shown.

Embodiment 2

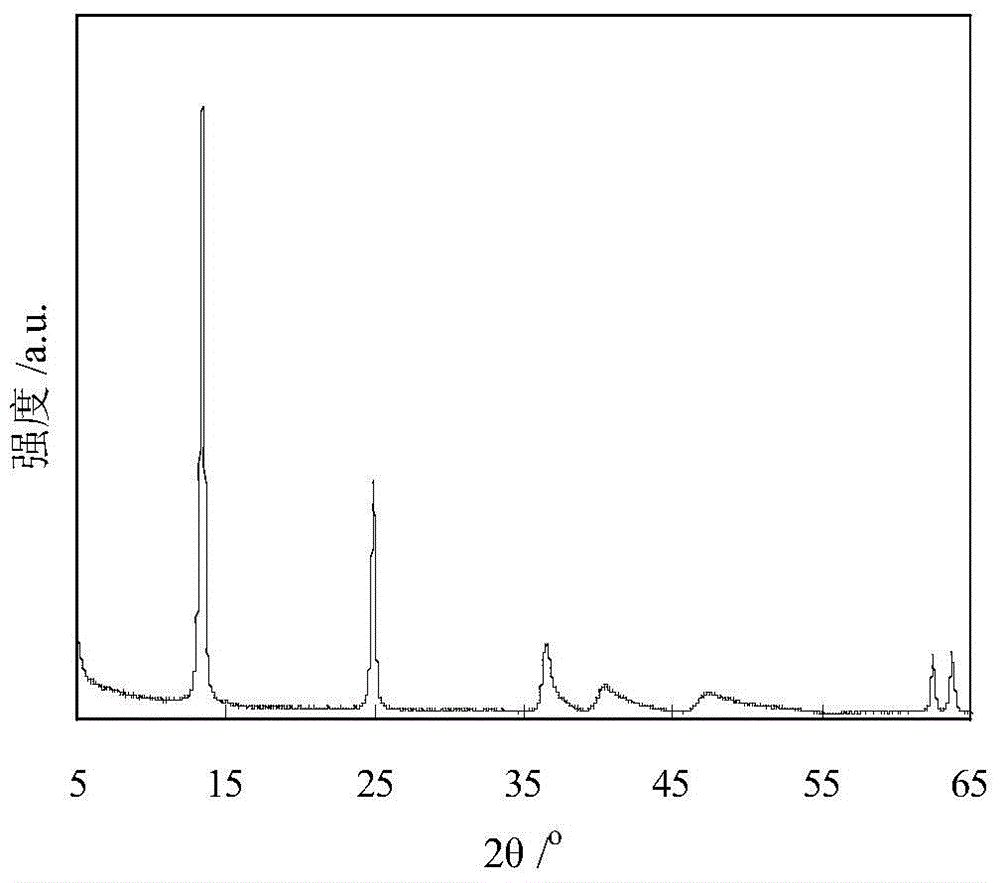

[0030] Weigh 48.1g of Mg(NO 3 ) 2 ·6H 2 O, 11.7g of Al(NO 3 ) 3 9H 2 O and 12.6g of Fe(NO 3 ) 3 9H 2 O, configured as 500ml of an aqueous solution with a total concentration of metal ions of 0.5mol / L. Weigh 16g of NaOH and 13.25g of Na 2 CO 3 configured as OH - and CO 3 2- 500ml of aqueous solution with a total concentration of 1.05mol / L. The gas is nitrogen, and the flow rate is 20ml / min. Both the metal salt solution and the alkali solution enter the microchannel reactor at a flow rate of 100ml / min to contact, mix and react, and the reaction temperature is 80°C. Take part of the precipitate and put it into a hydrothermal reactor, and treat it at 100°C for 4h. The precipitate after hydrothermal treatment is fully washed with deionized water, and the precipitate obtained after centrifugation is nano-carbonate-type MgAlFe hydrotalcite. The XRD pattern analysis results of the hydrotalcite are shown in the attached Figure 5 Show.

Embodiment 3

[0032] Weigh 24.0g of Mg(NO 3 ) 2 ·6H 2 O, 27.3g of Ni(NO 3 ) 2 ·6H 2 O, 11.7g of Al(NO 3 ) 3 9H 2 O and 12.6g of Fe(NO 3 ) 3 9H 2 O, configured as 500ml of an aqueous solution with a total concentration of metal ions of 0.5mol / L. Weigh 16g of NaOH and 13.25g of Na 2 CO 3 configured as OH - and CO 3 2- 500ml of aqueous solution with a total concentration of 1.05mol / L. The gas is nitrogen, and the flow rate is 150ml / min. Both the metal salt solution and the alkali solution enter the microchannel reactor at a flow rate of 150ml / min to contact, mix and react, and the reaction temperature is 80°C. Take part of the precipitate and put it into a hydrothermal reactor, and treat it at 100°C for 4h. The precipitate after hydrothermal treatment is fully washed with deionized water, and the precipitate obtained after centrifugation is nano-carbonate-type MgNiFeAl hydrotalcite. The XRD pattern analysis results of this hydrotalcite are shown in the attached Figure 6 Show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com