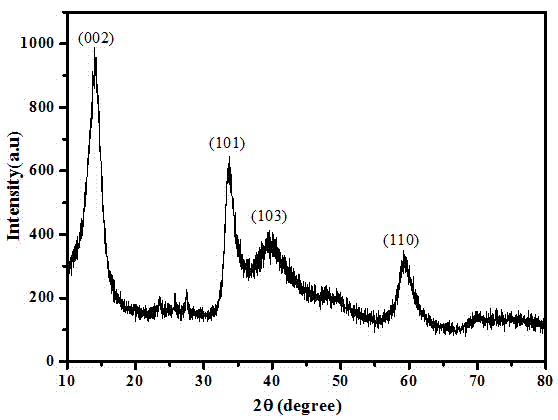

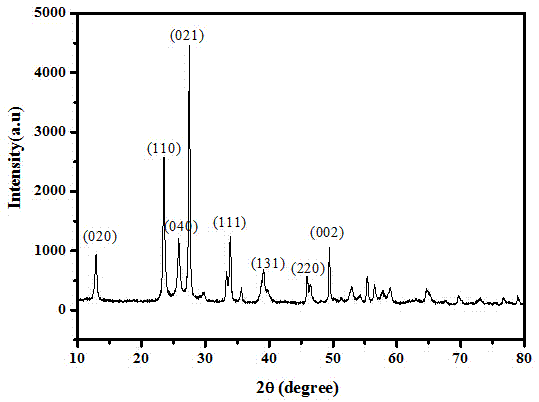

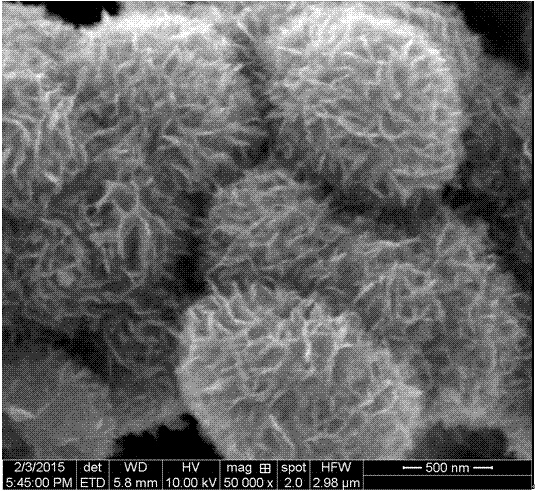

Preparation method of molybdenum trioxide microsphere in three-dimensional hierarchical structure

A molybdenum trioxide, three-dimensional technology, which is applied in the field of preparation of three-dimensional hierarchical flower spherical molybdenum trioxide microspheres, can solve the problems of no three-dimensional hierarchical structure flower spherical molybdenum trioxide microspheres preparation method, low purity, complicated process, etc. , to achieve the effect of short hydrothermal reaction time, simple equipment and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Weigh a certain amount of sodium molybdate and thiourea, and dissolve them in deionized water, wherein the concentration of sodium molybdate is 0.03 moles / liter, the concentration of thiourea is 0.112 moles / liter, and the moles of sodium molybdate and thiourea The ratio is 4:15;

[0025] (2) Add citric acid as an additive to the mixed solution obtained in step (1), wherein the molar ratio of citric acid to sodium molybdate is 1, stir magnetically at room temperature, and mix well;

[0026] (3) Move the mixed solution obtained in step (2) to a hydrothermal reaction kettle lined with polytetrafluoroethylene, and conduct a hydrothermal reaction at a temperature of 200°C for 21 hours, and then use the product after the hydrothermal reaction The centrifuge is used for solid-liquid separation, and the obtained solid product is washed several times with deionized water and ethanol;

[0027] (4) Place the solid product obtained in step (3) in a drying oven, dry at 60°C for...

Embodiment 2

[0030] (1) Weigh a certain amount of sodium molybdate and thiourea, dissolve them in deionized water, wherein the concentration of sodium molybdate is 0.04 mol / L, the concentration of thiourea is 0.15 mol / L, and the molar concentration of sodium molybdate and thiourea The ratio is 4:15;

[0031] (2) Add citric acid as an additive to the mixed solution obtained in step (1), wherein the molar ratio of citric acid to sodium molybdate is 1, stir magnetically at room temperature, and mix well;

[0032] (3) Move the mixed solution obtained in step (2) to a hydrothermal reaction kettle lined with polytetrafluoroethylene, conduct a hydrothermal reaction at 200°C for 22 hours, and then use the product after the hydrothermal reaction The centrifuge is used for solid-liquid separation, and the obtained solid product is washed several times with deionized water and ethanol;

[0033] (4) Place the solid product obtained in step (3) in a drying oven, dry at 60°C for 24 hours, then put it in ...

Embodiment 3

[0035] (1) Weigh a certain amount of sodium molybdate and thiourea, and dissolve them in deionized water, wherein the concentration of sodium molybdate is 0.02 mole / liter, the concentration of thiourea is 0.075 mole / liter, and the molar concentration of sodium molybdate and thiourea The ratio is 4:15;

[0036] (2) Add citric acid as an additive to the mixed solution obtained in step (1), wherein the molar ratio of citric acid to sodium molybdate is 1, stir magnetically at room temperature, and mix well;

[0037] (3) Move the mixed solution obtained in step (2) to a hydrothermal reaction kettle lined with polytetrafluoroethylene, conduct a hydrothermal reaction at a temperature of 190°C for 24 hours, and then use the product after the hydrothermal reaction The centrifuge is used for solid-liquid separation, and the obtained solid product is washed several times with deionized water and ethanol;

[0038] (4) Place the solid product obtained in step (3) in a drying oven, dry at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com