Dysprosium-doped hexagonal yttrium aluminate ceramic powder and preparation method thereof

A technology of ceramic powder and yttrium aluminate, which is applied in the field of dysprosium-doped hexagonal yttrium aluminate ceramic powder and its preparation, can solve the problems of long reaction time, difficulty in obtaining YAH powder, slow heating and cooling rate, and achieve good The effect of sintering activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

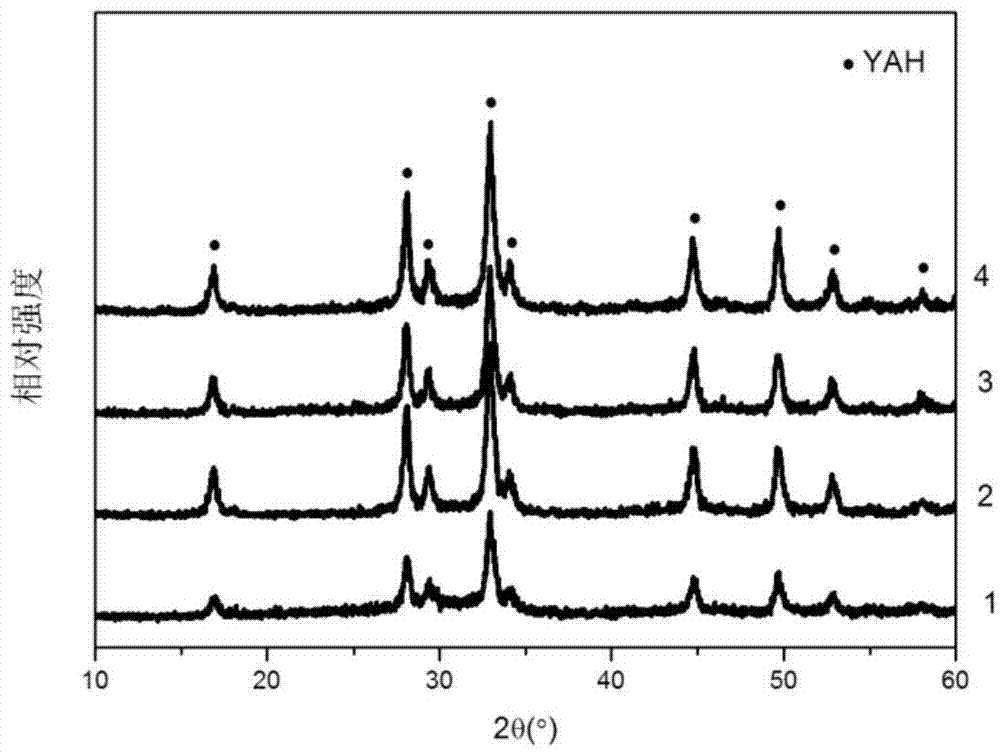

Embodiment 1

[0032] A kind of preparation method of dysprosium doped hexagonal yttrium aluminate ceramic powder, is characterized in that, comprises the following steps:

[0033](1) Dysprosium nitrate pentahydrate, yttrium nitrate hexahydrate, aluminum nitrate nonahydrate and citric acid monohydrate are mixed according to the molar ratio of 0.5%:3 (1-0.5%):5:4, dissolved in deionized water, and added Ammonia water was used to adjust the pH to 1, and after fully stirring, the water was evaporated and dried to obtain a xerogel; the xerogel was heat-treated at 700°C in a muffle furnace, and the precursor powder was obtained after ball milling and drying;

[0034] (2) Place the precursor powder in a graphite reactor, place the graphite reactor in a high-current reaction device (discharge plasma sintering equipment), keep the atmosphere in the graphite reactor as a non-oxidizing atmosphere, and apply a pulse current to the graphite reactor , so that it was heated to a temperature of 800°C at a ...

Embodiment 2

[0038] A kind of preparation method of dysprosium doped hexagonal yttrium aluminate ceramic powder, is characterized in that, comprises the following steps:

[0039] (1) Dysprosium nitrate pentahydrate, yttrium nitrate hexahydrate, aluminum nitrate nonahydrate and citric acid monohydrate are mixed according to the molar ratio of 2%:3 (1-2%):5:4, dissolved in deionized water, and added Ammonia water was used to adjust the pH to 1.5. After fully stirring, the water was evaporated and dried to obtain a xerogel; the xerogel was heat-treated at 740°C in a muffle furnace, and the precursor powder was obtained after ball milling and drying;

[0040] (2) Place the precursor powder in a graphite reactor, place the graphite reactor in a high-current reaction device (discharge plasma sintering equipment), keep the atmosphere in the graphite reactor as a non-oxidizing atmosphere, and apply a pulse current to the graphite reactor , so that it was heated to a temperature of 840°C at a heati...

Embodiment 3

[0044] A kind of preparation method of dysprosium doped hexagonal yttrium aluminate ceramic powder, is characterized in that, comprises the following steps:

[0045] (1) Dysprosium nitrate pentahydrate, yttrium nitrate hexahydrate, aluminum nitrate nonahydrate and citric acid monohydrate are mixed according to the molar ratio of 4%:3 (1-4%):5:4, dissolved in deionized water, and added Ammonia water was used to adjust the pH to 2. After fully stirring, the water was evaporated and dried to obtain a xerogel; the xerogel was heat-treated at 720°C in a muffle furnace, and the precursor powder was obtained after ball milling and drying;

[0046] (2) Place the precursor powder in a graphite reactor, place the graphite reactor in a high-current reaction device (discharge plasma sintering equipment), keep the atmosphere in the graphite reactor as a non-oxidizing atmosphere, and apply a pulse current to the graphite reactor , so that it was heated to a temperature of 810°C at a heating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| luminous efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com