Barium strontium titanate pyroelectric ceramic prepared from uniform fine grains and preparation method thereof

A technology of pyroelectric ceramics and barium strontium titanate, which is applied in the field of uniform fine-grain barium strontium titanate pyroelectric ceramics and its preparation, can solve problems such as difficulty in obtaining uniform fine-grain BST pyroelectric ceramics, and achieve Solve the effect of large and uneven grain size, uniform grain size and high performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

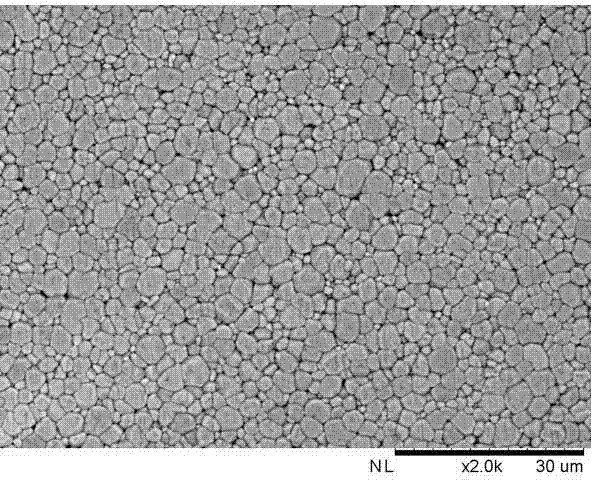

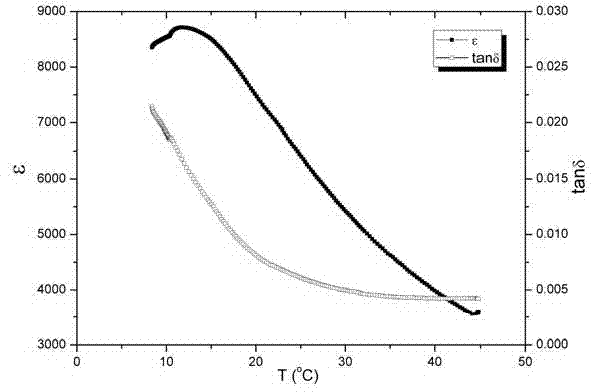

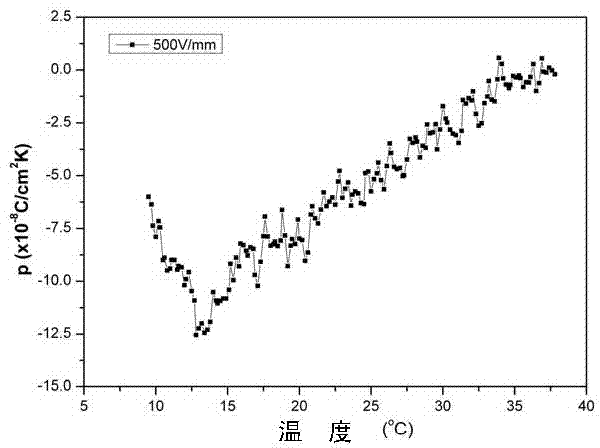

Image

Examples

preparation example Construction

[0035] More specifically, the preparation method of the uniform fine-grain barium strontium titanate pyroelectric ceramics includes:

[0036] (1) Weigh the raw material BaCO according to the stoichiometric ratio 3 , SrCO 3 、TiO 2 , Fe 2 o 3 , MnCO 3 And the oxide of A, mixed evenly by wet ball milling process, after drying, add 4-10wt% deionized water according to the weight of the raw materials to briquetting, and keep warm at 1000-1200°C for 1-2 Obtain strontium barium titanate block in 3 hours; Then the gained strontium barium titanate block is pulverized and sieved to obtain (Ba 1-x Sr x ) 1-a-b A a+b Ti 1-a-b Fe a mn b o 3 Powder;

[0037] (2) Income (Ba 1-x Sr x ) 1-a-b A a+b Ti 1-a-b Fe a mn b o 3 The powder is mixed evenly by wet ball milling process, after drying, a specified amount of binder is added, after granulation, aging, sieving, pre-pressing, isostatic pressing molding, and plastic discharge to obtain the barium strontium titanate green bo...

Embodiment 1

[0049] Embodiment 1 (preparation 6mol, 1313.87 grams)

[0050] Weigh raw material powder BaCO 3 (849.14g), SrCO 3 (249.09g) and TiO 2 (475.55g), and Fe 2 o 3 (4.45g), MnCO 3 (1.66g) and Y 2 o 3 (7.86) gram powder, all powders are mixed evenly with wet ball milling process; The mass ratio of material, ball milling medium and deionized water is 1:1.5:1.2, and the ball milling time is 24 hours, and ball milling medium is agate ball;

[0051] Dry the abrasive, add deionized water with 4% of the total powder mass, briquette, and synthesize in the air at a synthesis temperature of 1150°C and a holding time of 2 hours to obtain BST blocks; pulverize, pass through a 40-mesh sieve, and use wet The ball milling process makes the powder mix evenly; the mass ratio of material, ball milling medium and deionized water is 1:2.0:0.8, the ball milling time is 48 hours, and the ball milling medium is agate ball;

[0052] Drying, adding PVA solution as a binder, granulating, aging for 24...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

| Pyroelectric coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com