Method for producing THEIC

A technology of cyanuric acid and triethylamine, applied in the direction of organic chemistry, can solve the problems of high energy consumption and long process, and achieve the effects of improving quality, shortening reaction time and ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

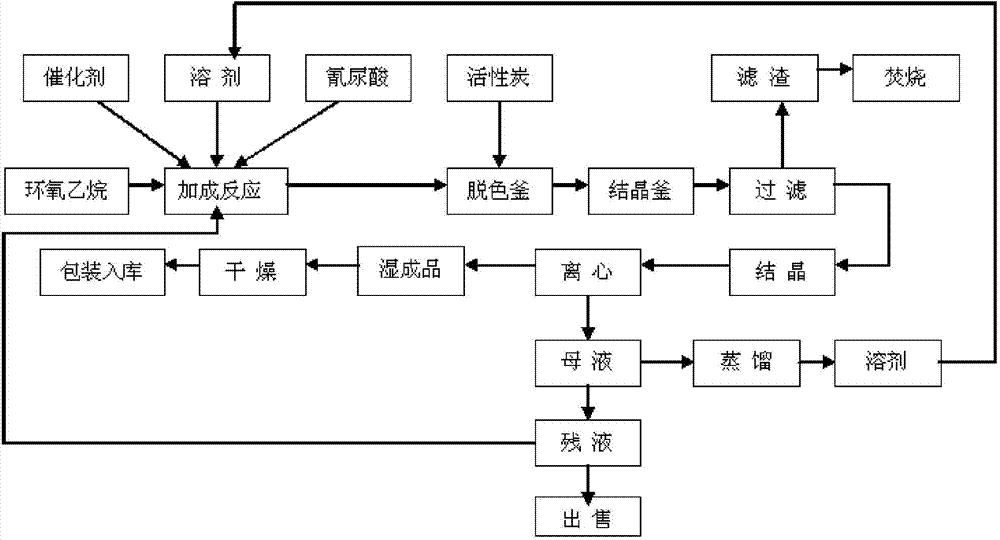

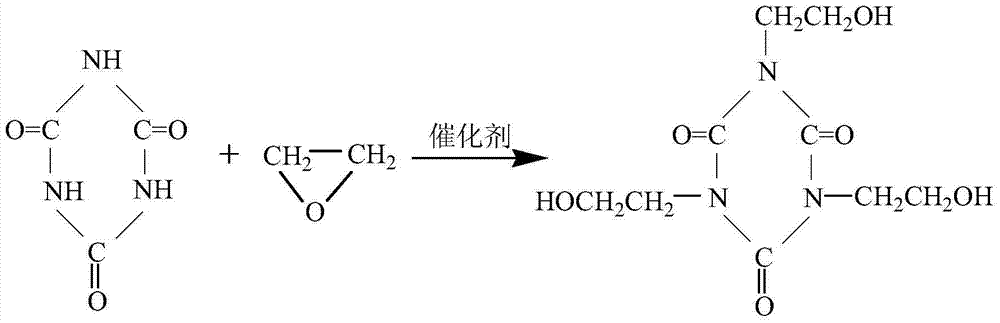

Method used

Image

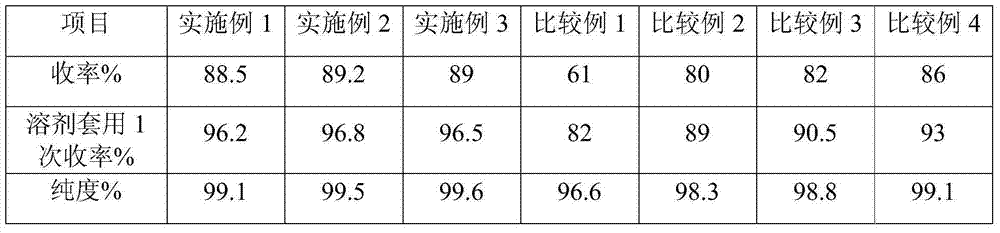

Examples

Embodiment 1

[0022] Put 200 grams of cyanuric acid, 400 grams of methanol, 3 grams of solid catalyst tetramethylammonium chloride and 1.5 grams of liquid catalyst triethylamine into a 2000L pressure reactor, at 90 ° C, 5 kg of pressure, within 2 hours 210 grams of ethylene oxide, then keep warm for 1 hour, cool down to 30°C, add 2 grams of activated carbon, heat and decolorize at 50°C, remove the active carbon layer by hot filtration, cool the filtrate to 10°C and centrifuge to get a wet product, bake Well done.

Embodiment 2

[0024] Put 200 grams of cyanuric acid, 400 grams of methanol, 6 grams of solid catalyst tetramethylammonium chloride and 3 grams of liquid catalyst triethylamine into a 2000L pressure reactor, and feed it within 3 hours at 100 °C and 6 kg of pressure 225 grams of ethylene oxide, then keep warm for 2 hours, cool down to 35°C, add 3 grams of activated carbon, heat and decolorize at 60°C, remove the active carbon layer by hot filtration, cool the filtrate to 15°C and centrifuge to get a wet product, bake Well done.

Embodiment 3

[0026] Put 200 grams of cyanuric acid, 400 grams of ethanol, 4 grams of solid catalyst tetramethylammonium chloride and 2 grams of liquid catalyst triethylamine into a 2000L pressure reactor, and feed it within 3 hours at 95 °C and 6 kg of pressure 220 grams of ethylene oxide, then keep warm for 1.5 hours, cool down to 30°C, add 2.5g of activated carbon, heat and decolorize at 55°C, remove the active carbon layer by hot filtration, cool the filtrate to 15°C and centrifuge to get a wet product, bake Well done.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com