Novel water-based alkyd resin coating and preparation method thereof

A water-based alkyd resin, alkyd resin technology, used in antifouling/underwater coatings, polyester coatings, coatings, etc., can solve the problem of no antibacterial sterilization, improve compatibility, improve antibacterial The effect of long-term bactericidal and antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

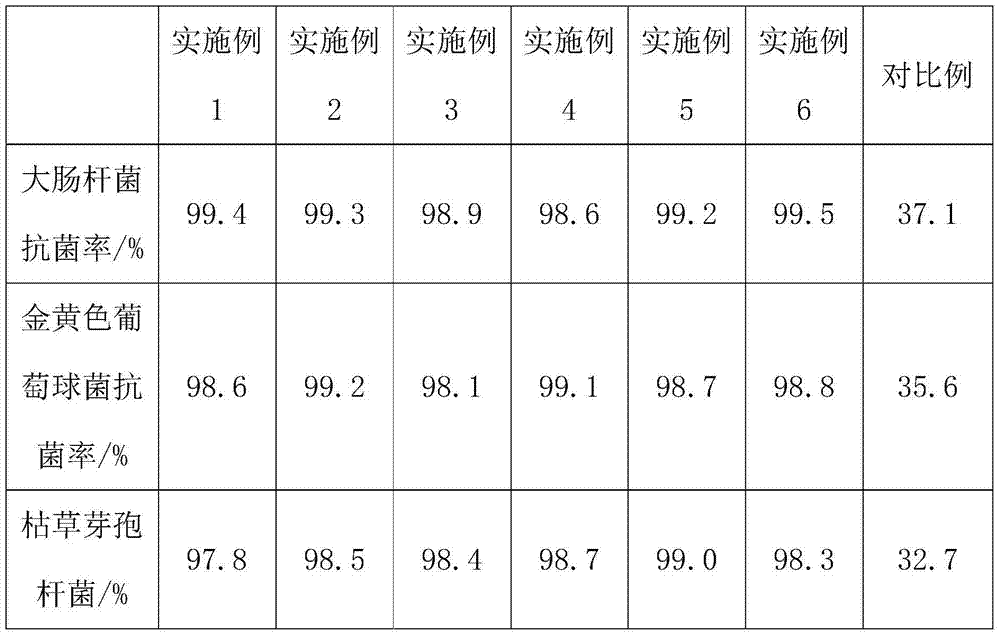

Examples

Embodiment 1

[0026] A new type of water-based alkyd resin coating, its parts by weight consist of: 45 parts of alkyd resin, 0.3 part of silver-loaded hydroxyapatite, 0.6 part of carboxylate, 5 parts of peppermint extract, alkyd resin-maleic anhydride copolymer 1.4 parts, 10 parts of titanium dioxide, 5 parts of barium sulfate, 9 parts of toluene, 0.2 parts of iron isooctanoate, 0.1 parts of acrylic acid, 16 parts of deionized water.

[0027] The steps of its preparation method are as follows:

[0028] (1) Place silver-loaded hydroxyapatite in a drying oven at 100°C for 3 hours, move it to a mixer, add glyceryl oleate and stir for 12 minutes at 95°C at a stirring speed of 300r / min, add alkyd resin Continue to stir for 15 minutes, move to a twin-screw extruder to extrude and granulate to obtain pellets, place the pellets in a grinder and grind for 5 hours to obtain silver-loaded hydroxyapatite masterbatch powder;

[0029] (2) Crush fresh mint leaves and add them to distilled water, move the...

Embodiment 2

[0032] A new type of water-based alkyd resin coating, its parts by weight consist of: 55 parts of alkyd resin, 0.6 part of silver-loaded hydroxyapatite, 0.5 part of carboxylate, 6 parts of peppermint extract, alkyd resin-maleic anhydride copolymer 1.8 parts of carbon black, 20 parts of carbon black, 14 parts of calcium carbonate, 7 parts of ethyl acetate, 0.1 part of iron isooctanoate, 0.2 parts of acrylic acid, and 13 parts of deionized water.

[0033] The steps of its preparation method are as follows:

[0034] (1) Place silver-loaded hydroxyapatite in a drying oven at 100°C for 3 hours, move it to a mixer, add glyceryl oleate and stir for 12 minutes at 95°C at a stirring speed of 300r / min, add alkyd resin Continue to stir for 15 minutes, move to a twin-screw extruder to extrude and granulate to obtain pellets, place the pellets in a grinder and grind for 5 hours to obtain silver-loaded hydroxyapatite masterbatch powder;

[0035] (2) Crush fresh mint leaves and add them to ...

Embodiment 3

[0038] A new type of water-based alkyd resin coating, its parts by weight consist of: 66 parts of alkyd resin, 0.5 part of silver-loaded hydroxyapatite, 0.9 part of carboxylate, 8 parts of peppermint extract, alkyd resin-maleic anhydride copolymer 2 parts, 15 parts of titanium dioxide, 10 parts of calcium carbonate, 7.5 parts of toluene, 0.5 parts of calcium naphthenate, 0.2 parts of acrylic acid, 14 parts of deionized water.

[0039] The steps of its preparation method are as follows:

[0040] (1) Place silver-loaded hydroxyapatite in a drying oven at 100°C for 3 hours, move it to a mixer, add glyceryl oleate and stir for 12 minutes at 95°C at a stirring speed of 300r / min, add alkyd resin Continue to stir for 15 minutes, move to a twin-screw extruder to extrude and granulate to obtain pellets, place the pellets in a grinder and grind for 5 hours to obtain silver-loaded hydroxyapatite masterbatch powder;

[0041] (2) Crush fresh mint leaves and add them to distilled water, mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com