A kind of high-strength antibacterial plastic and its preparation method

An antibacterial plastic, high-strength technology, applied in antifouling/underwater coatings, biocide-containing paints, coatings, etc., can solve the problems of low mechanical strength and short-term antibacterial effect of antibacterial plastics, and achieve high-efficiency sterilization and antibacterial Bacterial performance, excellent antibacterial performance, high strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

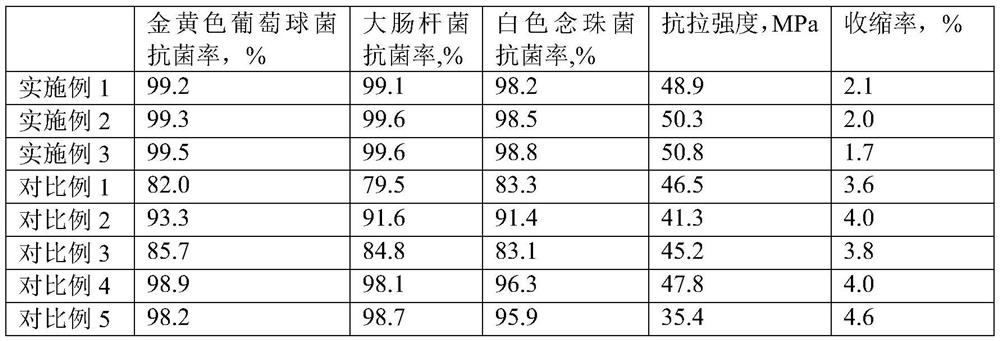

Examples

Embodiment 1

[0028] A high-strength antibacterial plastic comprises the following raw materials, in parts by weight, 36 parts of polyvinyl chloride, 25 parts of filler, 16 parts of modifier, 5 parts of antibacterial agent, 1 part of coloring agent, and 0.7 part of lubricant.

[0029] A preparation method for high-strength antibacterial plastics, comprising the following steps;

[0030] (1) Disperse tetrabutyl titanate in an aqueous solution and react for 2 minutes; add hydrogen peroxide and lithium hydroxide solution, stir, heat up to 100°C, react for 1 hour, and filter to obtain substance A; anneal the substance A, and add acetic acid solution until the pH is 6.8, washed, and dried; add nitric acid solution, heat up to 215°C, and react for 6 hours to obtain titanium dioxide nanowires; dissolve titanium dioxide nanowires in absolute ethanol, stir, heat up to 90°C, and add nano silver Particles and 3-aminopropyltrimethoxysilane are stirred to obtain an antibacterial agent;

[0031] (2) Pre...

Embodiment 2

[0035] A high-strength antibacterial plastic comprises the following raw materials in parts by weight: 42 parts of polyvinyl chloride, 27 parts of filler, 18 parts of modifier, 5 parts of antibacterial agent, 3 parts of coloring agent, and 0.8 part of lubricant.

[0036] A preparation method for high-strength antibacterial plastics, comprising the following steps;

[0037] (1) Disperse tetrabutyl titanate in aqueous solution, react for 2-8min; add hydrogen peroxide and lithium hydroxide solution, stir, heat up to 107°C, react for 1.5h, filter to obtain substance A; anneal treatment on substance A , add acetic acid solution until the pH is 7.0, wash and dry; add nitric acid solution, heat up to 220°C, and react for 6.5h to obtain titanium dioxide nanowires; dissolve titanium dioxide nanowires in absolute ethanol, stir, and heat up to 97°C , adding nano-silver particles and vinyltrimethoxysilane, stirring to obtain an antibacterial agent;

[0038] (2) Prepare modifier; mix diet...

Embodiment 3

[0042] A high-strength antibacterial plastic comprises the following raw materials, in parts by weight, 45 parts of polyvinyl chloride, 26 parts of filler, 19 parts of modifier, 7 parts of antibacterial agent, 2 parts of colorant, and 1.5 parts of lubricant.

[0043] A preparation method for high-strength antibacterial plastics, comprising the following steps;

[0044] (1) Disperse tetrabutyl titanate in an aqueous solution and react for 8 minutes; add hydrogen peroxide and lithium hydroxide solution, stir, heat up to 110°C, react for 2 hours, and filter to obtain substance A; anneal the substance A, add acetic acid solution until the pH is 7.2, washed, and dried; add nitric acid solution, heat up to 225°C, and react for 7 hours to obtain titanium dioxide nanowires; dissolve titanium dioxide nanowires in absolute ethanol, stir, heat up to 100°C, and add nano silver Particles and 3-aminopropyltrimethoxysilane are stirred to obtain an antibacterial agent;

[0045] (2) Prepare m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com