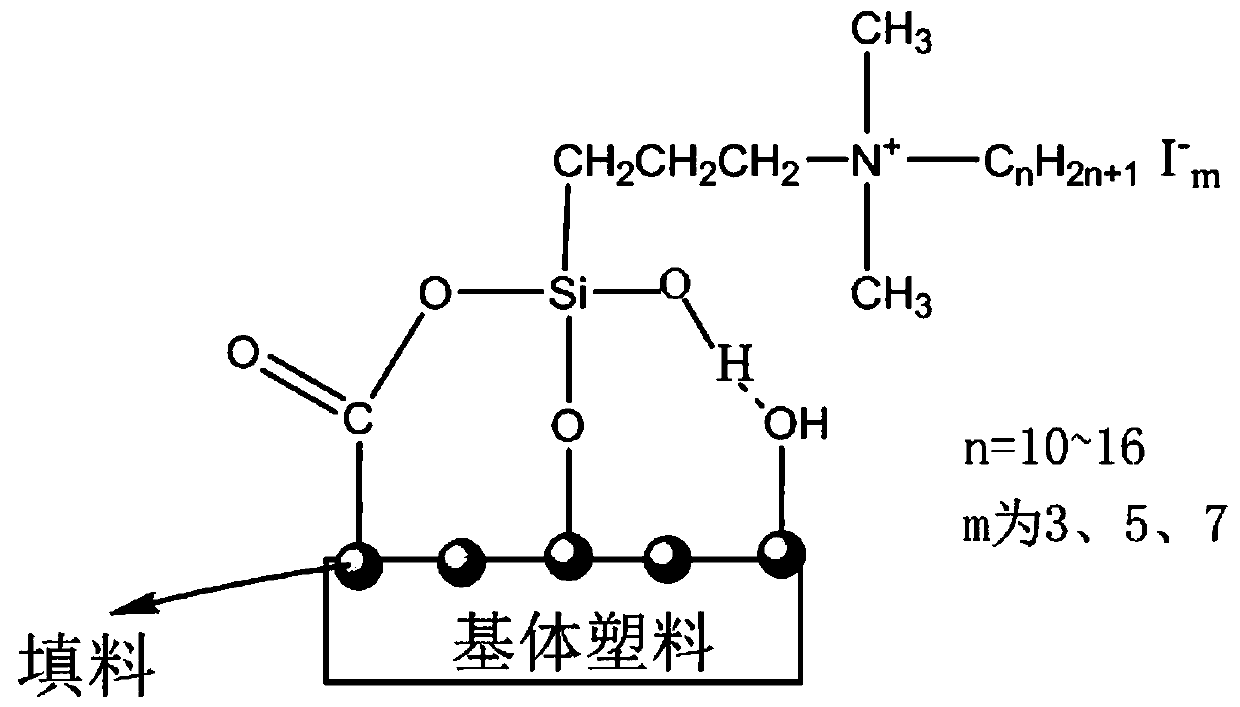

Antibacterial plastic with high polyiodine surface and its preparation method and application

A surface antibacterial, high iodine technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

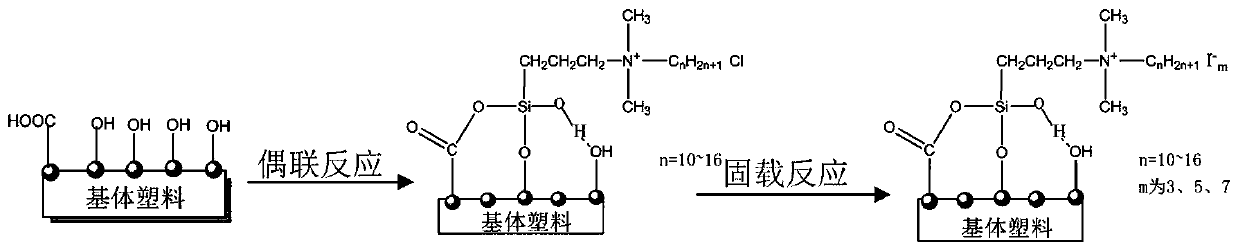

Method used

Image

Examples

Embodiment 1

[0033] Configuration of the coupling solution: add 3.60g of organic silicon quaternary ammonium salt to 894.50g of ethanol aqueous solution (the volume ratio of ethanol and water is 1:2) under stirring conditions to obtain the coupling liquid, wherein the organic silicon quaternary ammonium salt It is 3-(trimethoxysilyl)propyltetradecyldimethylammonium chloride.

[0034] Coupling reaction: put the substrate plastic film to be treated in the above coupling solution, react at 60°C and shaking for 10 minutes, take it out after the reaction, dry at 70°C for 10 minutes, and set aside.

[0035] The configuration of the carrier liquid: Add 1.12g of potassium iodide, 5.14g of iodine, and 1.79g of citric acid in sequence under ultrasonic conditions in an aqueous ethanol solution with a mass of 894.50g (the volume ratio of ethanol to water is 1:2). carrier fluid.

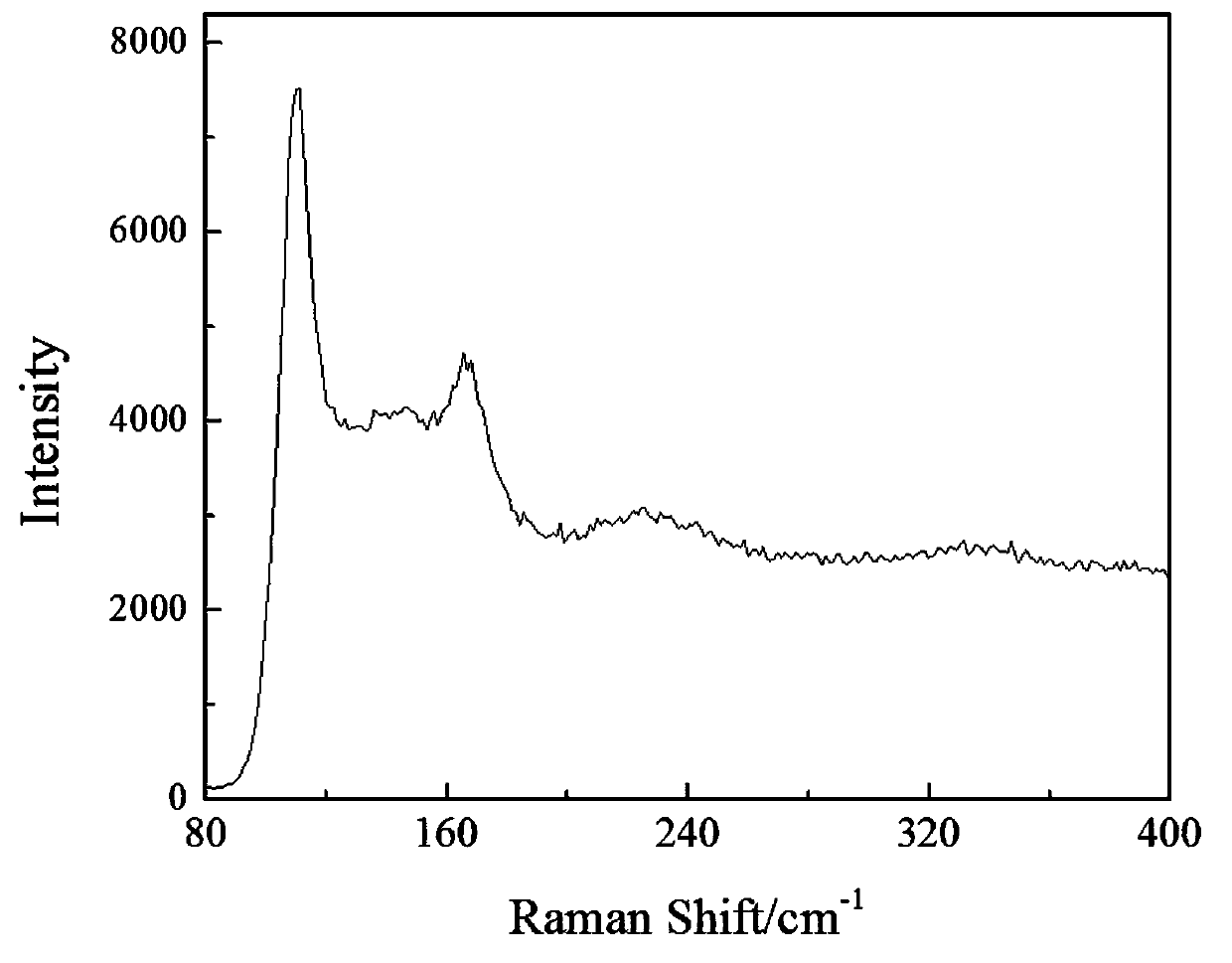

[0036] Immobilization reaction: put the base plastic after the coupling reaction in a beaker filled with the immobilizatio...

Embodiment 2

[0042] Configuration of the coupling solution: add 4.47g of organic silicon quaternary ammonium salt to 894.50g of ethanol aqueous solution (the volume ratio of ethanol and water is 1: 1) under stirring conditions to obtain the coupling liquid, wherein the organic silicon quaternary ammonium salt It is 3-(trimethoxysilyl)propyl dodecyldimethyl ammonium chloride.

[0043] Coupling reaction: put the substrate plastic film to be treated in the above coupling solution, react for 10 minutes at 60°C under shaking conditions, take it out after the reaction, dry at 60°C for 10 minutes, and set aside.

[0044] The configuration of the carrier liquid: add 1.12g of potassium iodide, 5.14g of iodine, and 1.79g of oxalic acid in sequence under ultrasonic conditions in an aqueous ethanol solution with a mass of 894.50g (the volume ratio of ethanol to water is 1: 1), and the carrier is obtained after dissolution liquid.

[0045] Immobilization reaction: place the base plastic film after the...

Embodiment 3

[0051] Configuration of the coupling solution: add 4.47g of organosilicon quaternary ammonium salt to 894.50g of ethanol aqueous solution (the volume ratio of ethanol and water is 2:1) under stirring conditions to obtain the coupling solution, wherein the organosilicon quaternary ammonium salt It is 3-(trimethoxysilyl)propyl dodecyldimethyl ammonium chloride.

[0052] Coupling reaction: put the base plastic film to be treated in the above coupling solution, react at 70°C for 10 minutes with shaking, take it out after the reaction, dry at 60°C for 10 minutes, and set aside.

[0053] The configuration of the carrier liquid: Add 0.93g of potassium iodide, 4.29g of iodine, and 2.68g of oxalic acid in sequence under ultrasonic conditions in an aqueous ethanol solution with a mass of 894.50g (the volume ratio of ethanol to water is 2:1), and the carrier is obtained after dissolution liquid.

[0054] Immobilization reaction: Place the base plastic film after the coupling reaction in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com